Injection molding applied to safer and more durable educational environments

Injection molding supports the creation of safe and durable educational environments by manufacturing technical plastic components designed for intensive daily use.

Injection molding supports the creation of safe and durable educational environments by manufacturing technical plastic components designed for intensive daily use.

Injection molding enables the local production of technical plastic components, supporting industrial recovery by strengthening manufacturing capacity, supply chains, and productive autonomy.

Injection molding enables the production of technical plastic components used in large-scale urban infrastructure projects such as the Bogotá Metro, ensuring durability, precision, and repeatability.

A technical guide explaining how preventive and corrective Mold Maintenance ensures efficiency, minimizes failures, and extends mold lifespan in industrial injection molding environments.

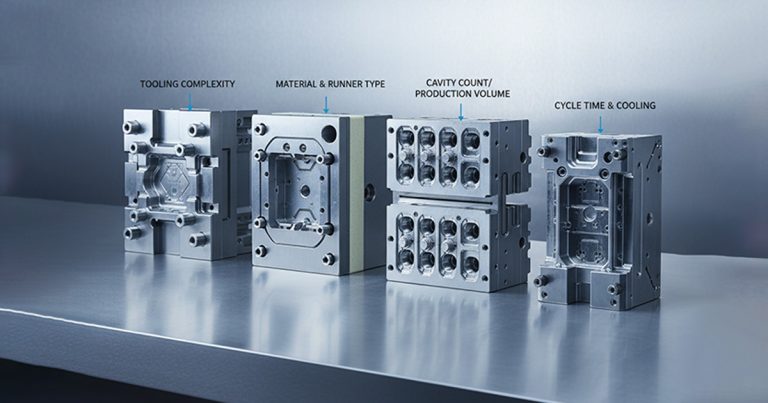

Understanding Injection Mold Cost begins with analyzing design complexity, materials, tooling requirements, and production goals. This summary explains the main factors that determine mold investment and long-term manufacturing efficiency.

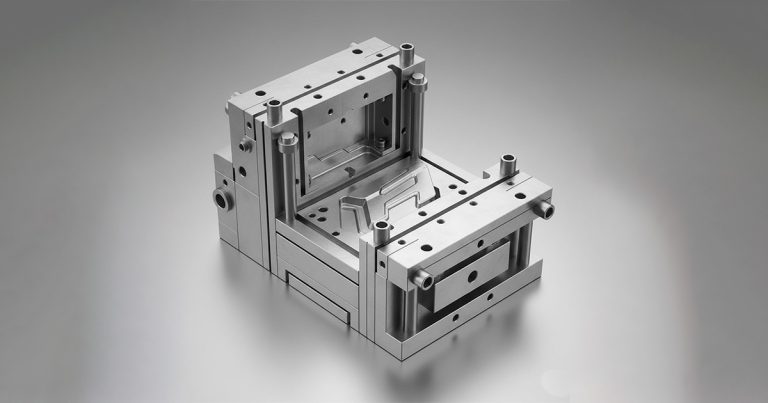

Discover the most important injection molding mold types, how each design works, and how they influence quality, cycle time, cost, and manufacturing performance.

Choosing the right plastic granules for injection molding determines mechanical performance, cost, and durability. This article explains how to select the ideal material for any project in 2026.

The strategic design of plastic injection molds defines cycle time, part quality, and production costs. Aquí analizamos cómo la ingeniería del molde transforma la eficiencia industrial.

High-precision plastic injection molding is redefining manufacturing standards with improved accuracy, faster cycles, and better performance across multiple industries.