What is Shielded Metal Arc Welding?

Shielded Metal Arc Welding (SMAW), commonly known as manual arc welding, is one of the most widely used welding processes in metal fabrication. It uses an electric arc between a coated electrode and the metal workpiece to melt both the electrode and the base metal, forming a solid and durable joint once cooled.

The coating on the electrode produces a shielding gas and a layer of slag that protects the molten metal from atmospheric contamination, ensuring strong and defect-free welds.

If you want to know more about the SMAW welding, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.

Understanding Welding in Modern Manufacturing

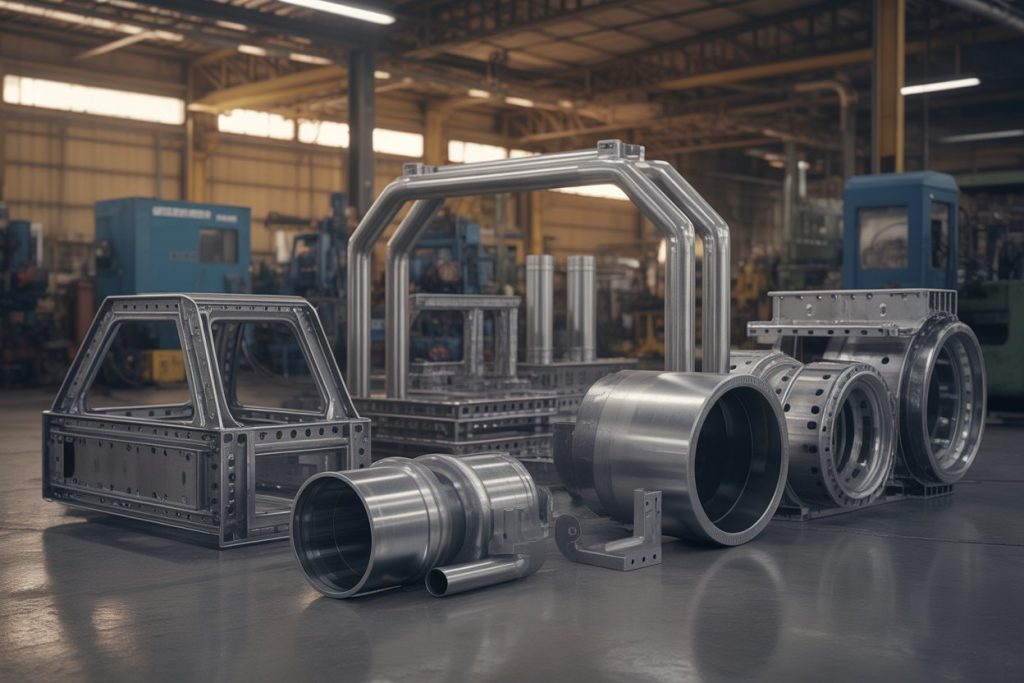

Welding is one of the most fundamental processes in modern metal fabrication. It allows different metal components to be permanently joined through the application of heat, pressure, or both, creating a solid bond that can withstand heavy mechanical stress. From small repair tasks to large-scale industrial production, welding ensures strength, precision, and structural integrity across countless applications.

There are many types of welding, including Shielded Metal Arc Welding (SMAW), Tungsten Inert Gas (TIG) Welding, Metal Inert Gas (MIG) Welding, and Plasma Arc Welding. Each method serves specific purposes depending on the type of metal, thickness, and environmental conditions. The selection of the right welding technique is critical to achieving durable and consistent joints.

Why Welding is Essential in the Metal Industry

The importance of welding in the metal industry cannot be overstated. It plays a key role in manufacturing everything from construction beams and automotive frames to pipelines, machinery, and custom industrial components. Unlike mechanical fastening, welding creates a metallurgical bond, producing seamless, high-strength structures.

Beyond its mechanical advantages, welding also supports design flexibility. Complex geometries, lightweight assemblies, and aesthetic finishes are possible when advanced welding processes are combined with machining, cutting, or polishing. This makes welding a vital step in the full manufacturing cycle — from prototyping to final production.

How the Welding Process Works

The SMAW welding process begins when the electrode tip touches the workpiece and an electric current flows, generating an arc of intense heat—often exceeding 6000°C.

This heat melts the metals, and as the welder moves the electrode, a continuous bead of molten material forms along the joint.

When the arc moves forward, the molten metal solidifies, creating a metallurgical bond. The slag layer that remains on top must be removed after each pass to expose the clean weld beneath.

Advantages of Shielded Metal Arc Welding

This welding process offers several practical and technical benefits, especially in construction, repair, and heavy manufacturing:

-

Versatility: Works with ferrous and non-ferrous metals, both indoors and outdoors.

-

Portability: Compact equipment ideal for field work or confined spaces.

-

Strong joints: Produces high mechanical resistance and long-lasting connections.

-

Cost-effective: Requires simple equipment and minimal maintenance.

-

Adaptability: Performs well in various positions—flat, vertical, or overhead.

Industrial Applications

SMAW is essential in sectors such as:

-

Structural fabrication: beams, frames, and supports.

-

Shipbuilding and marine repairs.

-

Pipe welding for oil, gas, and water lines.

-

Machinery and equipment maintenance.

-

Automotive restoration and heavy transport.

Its reliability makes it ideal for jobs where durability and field performance are crucial.

Best Practices for Quality Welds

To obtain consistent and precise results in welding operations, it’s important to:

-

Keep electrodes dry and free from moisture.

-

Clean surfaces of rust, oil, and contaminants before welding.

-

Maintain correct arc length and electrode angle.

-

Choose proper current (AC/DC) according to electrode type.

-

Control cooling time to prevent cracks and stress in the joint.

These measures help guarantee uniform, professional results—especially when combined with machining or finishing processes like CNC turning or metal polishing.

Conclusion

Shielded Metal Arc Welding remains a cornerstone of industrial fabrication due to its simplicity, efficiency, and strength. Despite technological advances in MIG or TIG welding, SMAW continues to be a reliable, field-proven process used worldwide for maintenance and construction tasks that demand precision and durability.