The Industrial Importance and Properties of Rubber

Rubber plays a critical role in multiple industries, with vulcanized rubber being especially valued for its versatility, durability, and adaptability. Its applications range from heavy-duty vulcanized rubber components in the construction, mining, and automotive sectors to consumer products that ensure safety, hygiene, and comfort in everyday life. This wide demand highlights the significance of vulcanized rubber manufacturing and the continuous innovation in rubber processing.

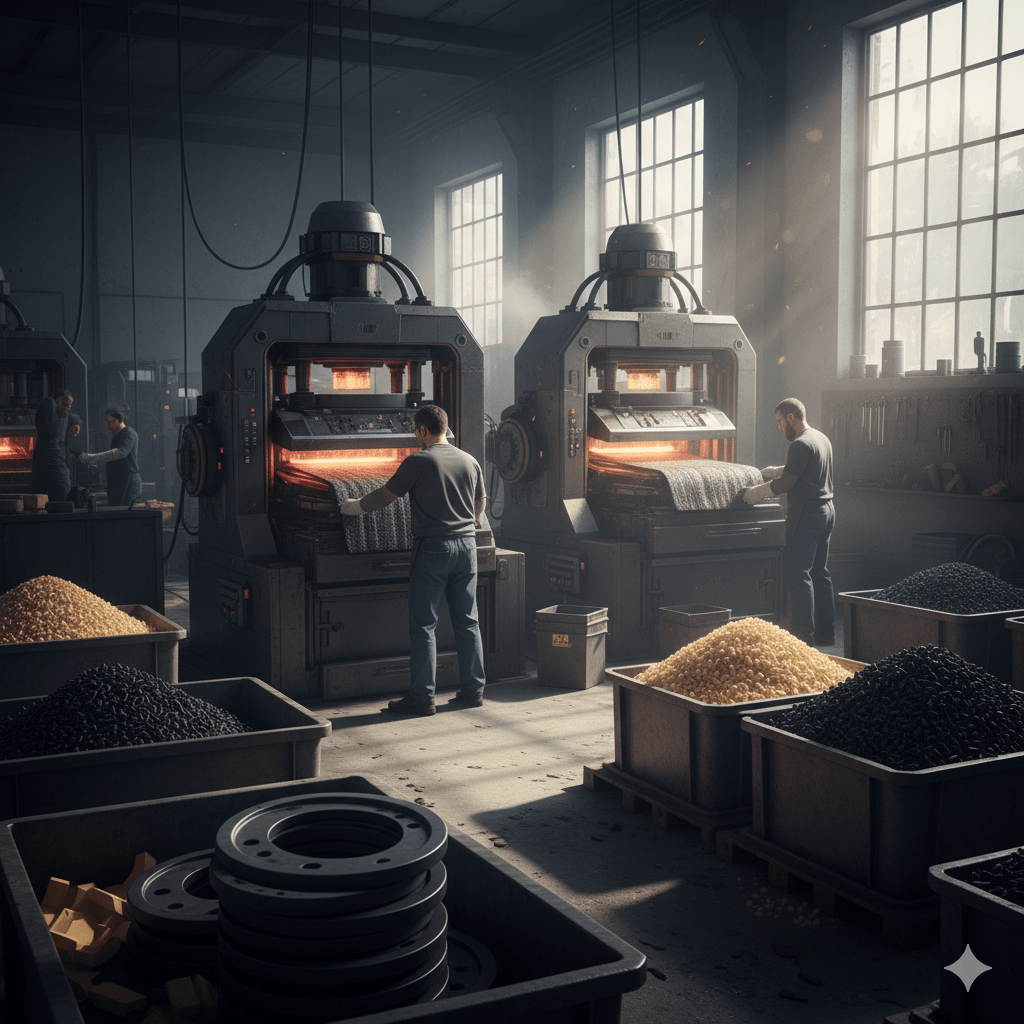

The rubber used today comes primarily from natural sources, extracted as latex sap from specific plants. However, a large portion is also synthetically produced, allowing engineers to customize vulcanized rubber properties for specialized industrial applications. Once collected, the raw rubber is compounded with carefully selected additives. When exposed to controlled heat, sulfur, and precise process parameters, the material undergoes vulcanization, transforming it into a more resilient and versatile vulcanized rubber product.

This cured state provides essential characteristics that make vulcanized rubber indispensable in industrial settings. It is resistant to chemical attack, maintaining its integrity when exposed to oils, solvents, and other harsh chemicals. The material gains enhanced hardness and durability, allowing it to withstand mechanical stress without permanent deformation. Additionally, vulcanized rubber does not melt or lose its form under high temperatures, ensuring reliable performance in demanding environments.

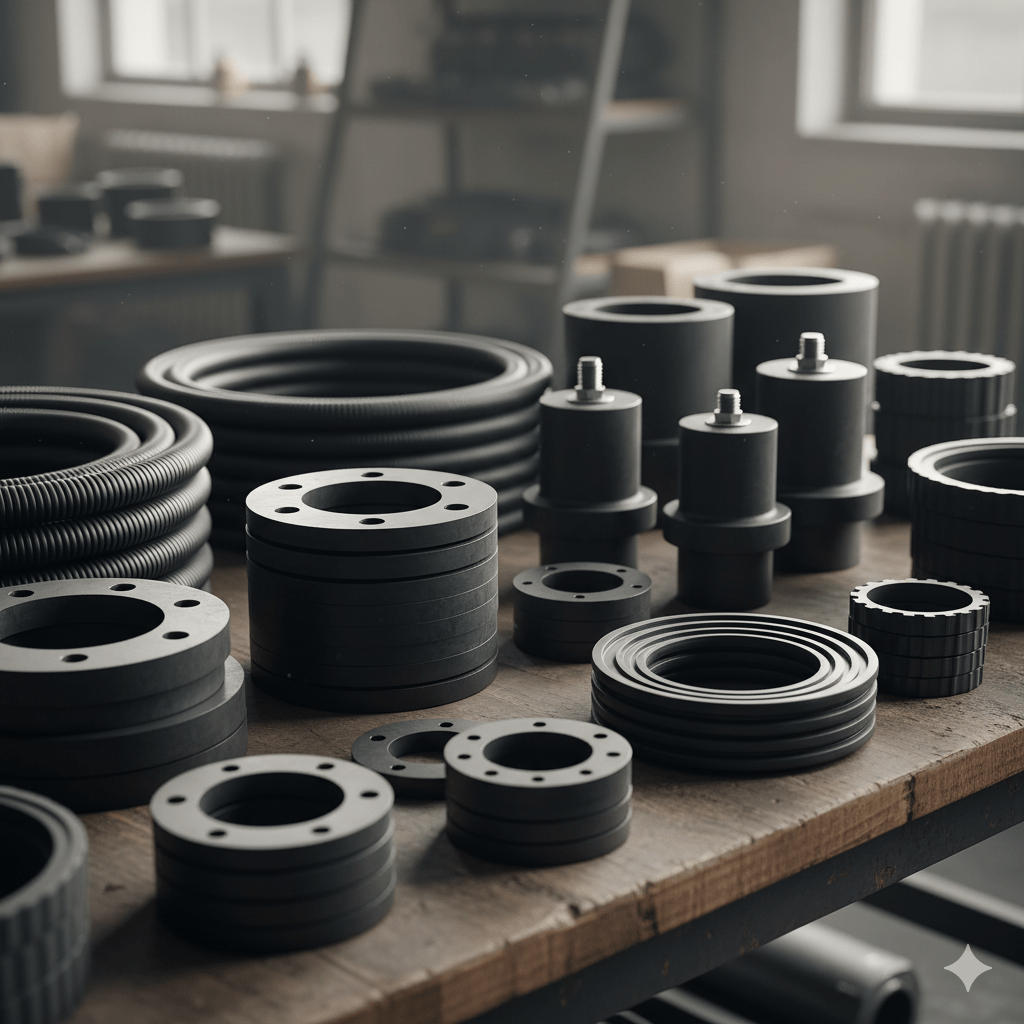

Beyond mechanical and chemical benefits, vulcanized rubber’s inherent elasticity and flexibility allow it to absorb shocks, vibrations, and impacts, making it ideal for industrial gaskets, seals, hoses, and protective rubber coverings. Its durability reduces the need for frequent maintenance or replacement, improving operational efficiency and lowering costs across industries.

Vulcanized rubber is also highly customizable, with the ability to be produced in various forms, including sheets, rods, extruded profiles, molded parts, and coated surfaces. This versatility ensures that vulcanized rubber components can be tailored to meet specific industry requirements, whether for high-performance mechanical applications, insulation, or environmental protection.

In summary, the industrial use of vulcanized rubber combines both natural and synthetic advantages, producing components that are strong, flexible, and chemically stable. These attributes make vulcanized rubber a cornerstone of modern manufacturing, supporting a wide range of applications from heavy-duty industrial components to everyday consumer products, ensuring durability, safety, and high performance.

Our experience in handling rubber and vulcanized

We specialize in the manufacture of customized rubber parts, tailored to meet the specific working conditions and operational requirements of each component. Our expertise covers a wide variety of elastomers, including Neoprene, Nitrile, EPDM, Silicone, SBR, Viton, Polybutadiene, and other high-performance rubber compounds.

Selecting the right type of rubber is now highly industry-specific, reflecting the demands of sectors ranging from construction and manufacturing to automotive, aerospace, and consumer goods. Despite this segmentation, we offer professional guidance and technical advice to ensure that your designs and projects achieve optimal performance and durability.

Our product lines are carefully designed to meet market standards and functional requirements, providing reliable, long-lasting solutions. Some of the key products and services we provide include:

-

Specialized Rubber Packing: Designed for chemical, mechanical, or thermal resistance applications.

-

Gym Rubber Flooring: High-durability, slip-resistant surfaces suitable for fitness facilities.

-

Dielectric Rubber Flooring: Electrical insulating floors that enhance workplace safety.

-

Vulcanizing Services: Custom vulcanization for improved elasticity and strength.

-

Structural Supports: Rubber components that absorb vibrations and protect machinery.

-

Expansion Joints: Flexible elements that compensate for thermal expansion and mechanical movement.

-

Rubber Seals: Precision-engineered seals for fluid containment and leak prevention.

-

Specialized Coatings: Protective rubber layers for industrial surfaces and equipment.

By leveraging our experience in elastomer processing, we help businesses develop components that not only meet operational specifications but also extend service life, reduce maintenance, and improve safety. Each solution is designed with material performance, environmental conditions, and end-use requirements in mind, ensuring that our rubber products provide maximum efficiency and reliability.

Through careful material selection, precise manufacturing, and tailored finishing processes, we can deliver custom rubber solutions that satisfy both technical and commercial requirements, making our services a strong alternative for companies seeking high-quality, industry-ready elastomer components.

If you want to know more about the Vulcanization, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.