The Injection Molding Process and Its Applications

Plastic has become an indispensable material in modern life due to its versatility and ability to take almost any shape. Its wide range of applications makes it ideal for multiple sectors, including construction, industrial, automotive, and hydrocarbons.

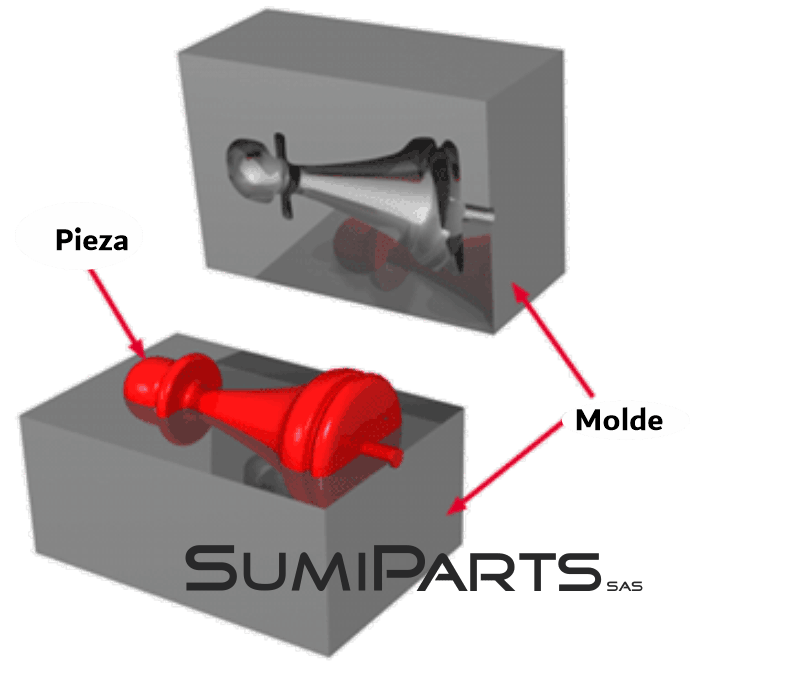

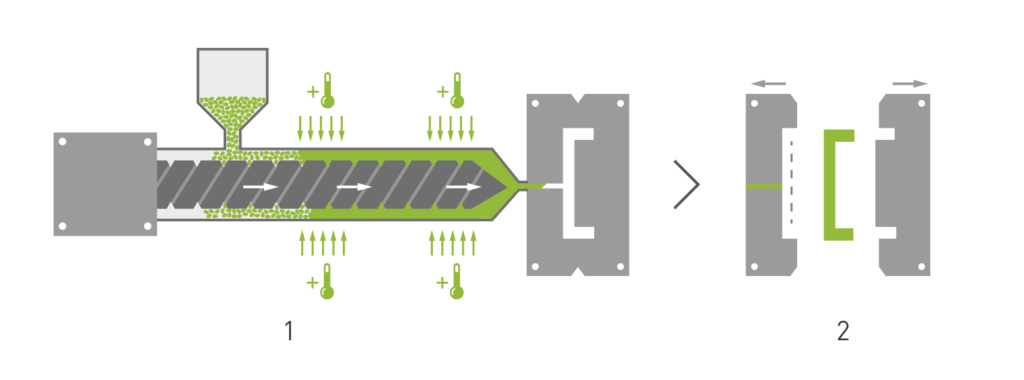

The injection molding process involves shaping plastic using a mold that can produce products with complex geometries. The process begins with melting the plastic resin, which is then fed through a hopper and injected into the mold under precise conditions. Once inside the mold, the material cools and solidifies, taking the exact shape and geometry of the mold.

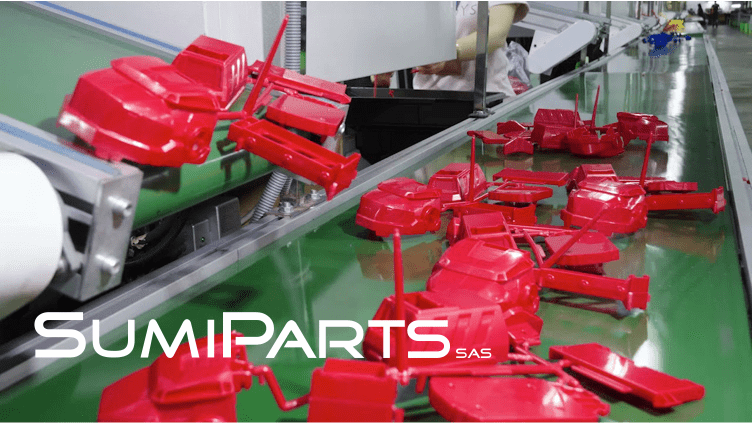

With injection molding, manufacturers can produce high-precision, repeatable parts efficiently, reducing waste and achieving consistent quality even in large production runs. This makes it a key technology for producing durable and complex plastic components across diverse industries.

Advanced Injection Molding Technology at Sumiparts

The injection molding process at Sumiparts is carried out using state-of-the-art, high-performance machines. These modern injection molding machines are capable of applying up to 200 tons of injection force, allowing precise shaping of plastic materials and achieving high-speed molding with fully programmable controls. This level of technology ensures consistent quality, repeatability, and the ability to handle complex production requirements.

With our injection molding capabilities, clients can develop innovative products and intricate geometries that would be difficult to achieve with conventional manufacturing methods. Sumiparts provides advanced design support tools that help anticipate potential issues during the design phase, optimizing both the mold and the process before production begins. This proactive approach guarantees that the final plastic parts not only meet but exceed expectations in terms of quality, durability, and surface finish.

Our high-tech injection molding systems also allow flexibility in material selection, enabling the production of parts from engineering plastics, composites, and other specialized polymers. Combined with precision molding and stringent quality control, Sumiparts ensures that every plastic component is produced efficiently, with minimal waste and superior structural integrity.

By leveraging cutting-edge machinery, expert design support, and robust quality management, Sumiparts’ injection molding services empower customers to bring their most complex and innovative plastic designs to life, reliably and at scale.

Additional Sections You Can Add

Adding real product examples helps potential clients understand what’s possible with your Injection Molding services:

-

Automotive components: housings, connectors, engine covers, interior parts.

-

Electronics: casings, switches, plugs, keypads, protective covers.

-

Medical and laboratory products: syringes, containers, plastic tools, diagnostic parts.

-

Furniture and accessories: joints, fittings, decorative elements, handles.

-

Construction and hydraulic systems: pipe fittings, valves, covers, and seals.

-

Consumer goods: bottles, kitchenware, toys, packaging, and containers.

In Sumiparts SAS we are part of leading companies in the industry of the development of molds for Plastic Injection, since the result of the formed products depends on the good quality of the mold and in part on a good design. Therefore, we emphasize that the design of a good mold is the key to success in plastic injection processes.

Our injection molding machines are fully equipped with advanced tools to produce a wide variety of plastic products with precision and consistency. Thanks to our robust quality control system, we are able to operate 24 hours a day, ensuring continuous production without compromising standards.

By unifying all processes—from design support to molding and finishing—Sumiparts offers clients enhanced service, flexibility, and efficiency. This integrated approach allows us to meet any custom requirement, ensuring that each part is produced accurately and reflects the original design intent. With our injection molding capabilities, customers benefit from reliable production, reduced lead times, and high-quality plastic components tailored to their needs.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click aquí , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.