Steel Molds - Manufacturing

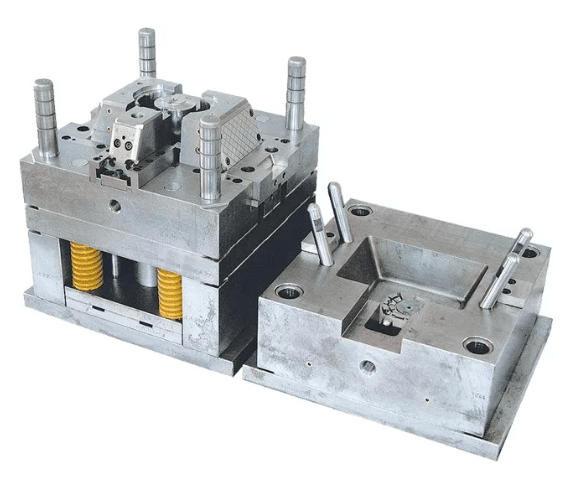

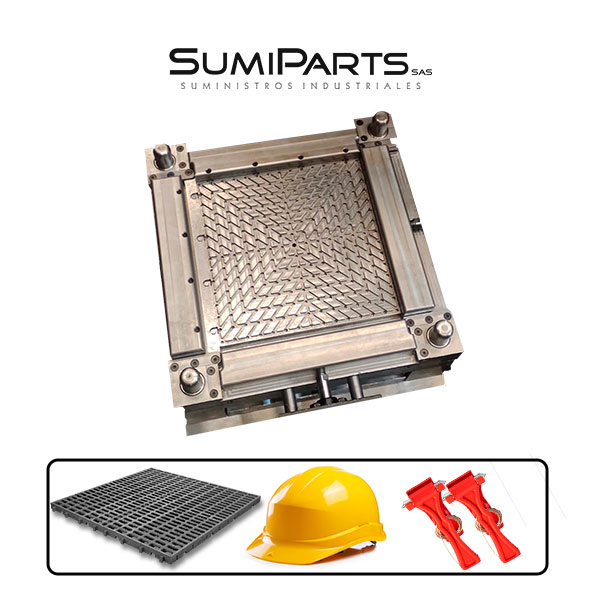

At SUMIPARTS, we specialize in the manufacturing of steel molds for industrial applications that demand precision, resistance, and repeatability. Our molds are engineered to deliver consistent quality and optimal performance in every production cycle — whether for plastic injection, rubber molding, or other specialized processes.

Materials & Products:

Steels: P20, Stavax, Mirrax 420, 4140, 1045

Products: metal parts, springs, welding wire, wire hooks, mesh, and industrial rings

We put our experience in the manufacturing of steel molds and plastic injection molds at your service.

Infrastructure with CNC technology, high-quality steels, optimized mold cooling developments, precision machining, and strict process control allow us to offer highly efficient, precise, and profitable molds.

Applications of Steel Molds

Steel molds are essential components across a wide range of industrial and manufacturing sectors due to their durability, dimensional precision, and ability to maintain consistent performance over long production cycles. Their versatility makes them indispensable in processes that demand both strength and fine detail.

1. Plastic Injection Molding:

Steel molds are the foundation of modern plastic manufacturing. They are used to produce automotive components, electronic housings, packaging, and consumer goods with exact dimensions and high repeatability. Their excellent heat resistance and thermal stability make them ideal for high-temperature thermoplastic injection, ensuring smooth part ejection and minimal deformation.

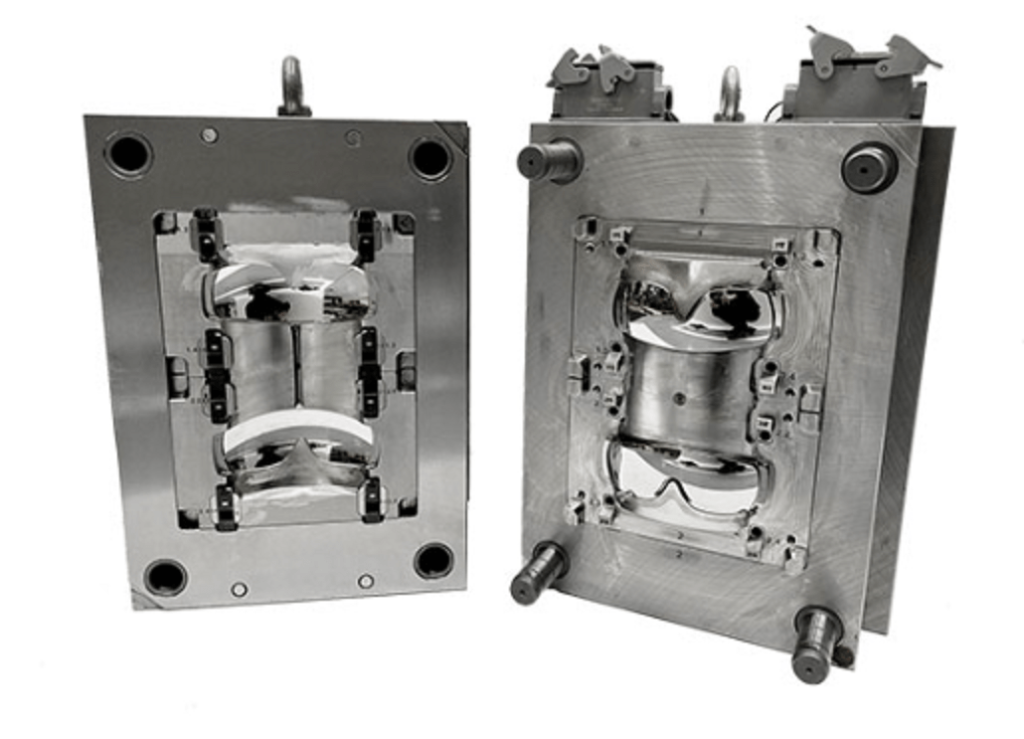

2. Rubber and Silicone Parts:

In the production of seals, gaskets, vibration dampers, and flexible connectors, steel molds offer the precision required to form complex geometries while withstanding the pressure and temperature variations typical of rubber curing processes. The polished surfaces and controlled cooling channels in these molds ensure a clean finish and consistent material properties.

3. Metal Casting and Die Casting:

Steel molds are also used in low-pressure and gravity casting applications, particularly for aluminum and zinc alloys. Their robustness enables them to resist the repeated exposure to molten metals, maintaining surface integrity and dimensional consistency throughout extended production runs.

4. Industrial and Custom Applications:

Beyond traditional uses, steel molds are increasingly applied in medical equipment, aerospace components, and high-precision industrial tools. Each mold is custom-engineered to meet the specific mechanical, thermal, and aesthetic requirements of the end product, allowing manufacturers to achieve tight tolerances and optimized material flow.

At SUMIPARTS, every mold is designed to perform reliably under extreme working conditions, offering superior resistance to wear, pressure, and temperature fluctuations. Whether used in small-batch prototyping or full-scale mass production, our steel molds ensure operational efficiency, consistent quality, and extended tool life, helping clients maximize productivity and minimize maintenance costs.

Engineering and Design Precision

Every steel mold begins with a robust CAD design and CAM programming phase. Using advanced 3D modeling and simulation software, our engineers ensure that every cavity, channel, and cooling line is optimized for productivity and longevity.

We perform finite element analysis (FEA) to identify stress points and improve mold durability, reducing maintenance time and ensuring dimensional accuracy throughout large production runs.

Sustainable and Cost-Effective Production

At SUMIPARTS, sustainability is integrated into every stage of steel mold manufacturing, from material selection to final finishing. Through optimized machining strategies, we minimize material waste, reduce tool wear, and improve energy efficiency across all operations. Advanced CNC technologies and process automation enable precise cutting paths and reduced cycle times, contributing to both economic and environmental efficiency.

We prioritize the use of recyclable and high-performance alloys, extending mold lifespan and reducing the frequency of replacements. This approach not only enhances productivity but also supports circular manufacturing practices, ensuring that materials can be recovered and reused with minimal impact on the environment.

Our eco-efficient production model focuses on balancing performance with sustainability. By applying predictive maintenance, coolant recycling systems, and energy-efficient machining centers, we achieve significant reductions in resource consumption and carbon emissions.

For our clients, this translates into high-performance molds with lower total cost of ownership (TCO) — combining durability, dimensional precision, and environmental responsibility. Every mold produced under these standards contributes to a more sustainable manufacturing ecosystem, without compromising the quality or reliability that defines SUMIPARTS.