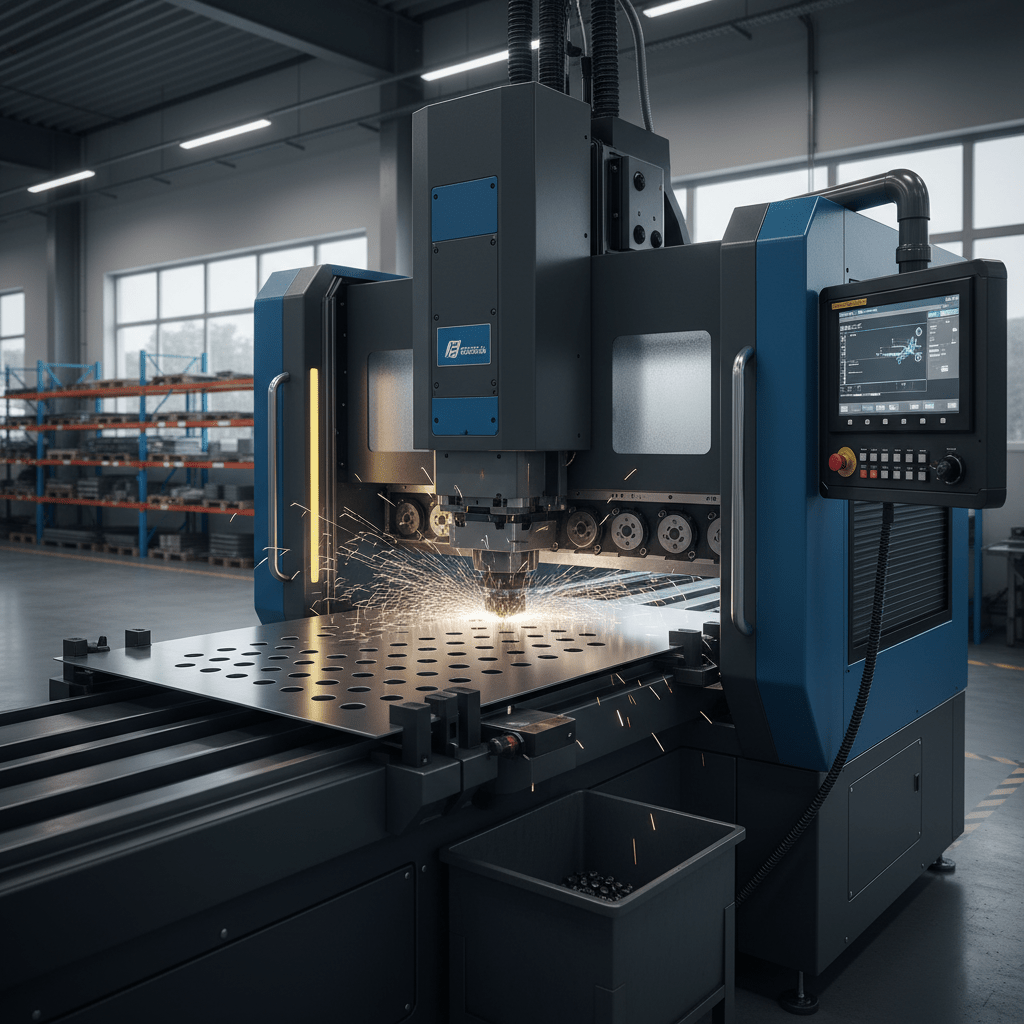

High-Accuracy Sheet Metal Punching Services at Sumiparts SAS

Sheet Metal Punching with CNC (Computer Numerical Control) technology is one of the key precision manufacturing processes we perform at Sumiparts SAS, leaders in industrial metal fabrication and processing. This advanced method allows us to achieve highly accurate, repeatable, and efficient results, making it ideal for complex industrial, architectural, and automotive applications.

Thanks to the computerized control system, every detail of the punching process is precisely programmed, ensuring a minimal margin of error through careful machine calibration and specialized punching software. This results in consistent dimensions, clean cuts, and superior quality finishes across all production runs.

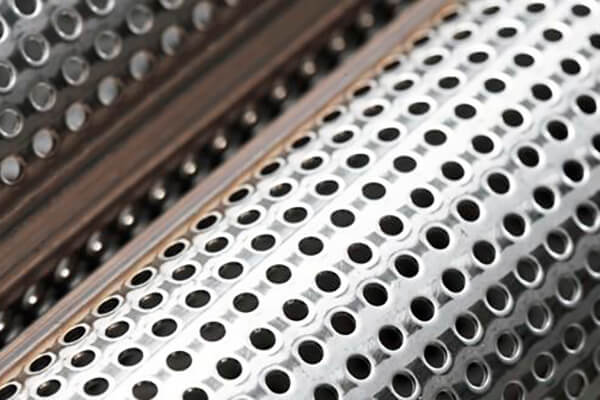

At Sumiparts SAS, our CNC Sheet Metal Punching service can be applied to a wide range of materials, including stainless steel, carbon steel, aluminum, and galvanized sheet metal. The process supports multiple operations such as lattice punching, cutting, trimming, and die-cutting, always maintaining the highest standards of precision and surface finish quality.

To optimize performance and cost efficiency, we utilize an extensive library of punch tool references, allowing us to adapt each project to its specific geometry and material thickness. This strategic tool selection not only guarantees dimensional accuracy but also helps reduce material waste and production time, resulting in greater efficiency and cost savings for our clients.

Whether for industrial equipment, architectural components, or automotive parts, our Sheet Metal Punching service combines cutting-edge technology, experienced operators, and strict quality control to deliver products that meet the most demanding technical requirements.

How is the Sheet Metal Punching process done?

This is a work that is carried out through the sheet and plate cutting , using a punch and a die. The application of punch forces on the material to be introduced creates an initial deformation, followed by a breakage of the material due to the rapid propagation of cracks between the cutting edges of the punch. The procedure results in a fairly obvious change.

Three stages are taken into account in the sheet metal punching process:

- Sheet Metal Punching Deformation: Produced by the punch on the metal sheet during the process, which originates in an elastic deformation around the edges of the punch and the die. This initial phase is critical in understanding the mechanism.

- Sheet Metal Punching Inclusion: It occurs when the cutting edges of the punch and the matrix manage to insert themselves into the material during the sheet metal punching operation, producing cracks in it along the cutting edges. This stage represents a fundamental step in the sheet metal punching sequence where material failure begins.

- The Sheet Metal Punching Fracture: After the cracks in the sheet originate from the sheet metal punching forces, the punch continues to descend to expel the cut material. This action completes the sheet metal punching cycle, resulting in the impregnation of the slug in the matrix and the successful expulsion of the cut material, finalizing the operation that creates precise openings in the metal sheet.

Any of the advantages of the punching of sheet metal are:

- They avoid scratches on the sheet and unnecessary movements since the material circulates in only one direction.

- Variety of up to 60 punches and dies In the machines used for punching, which can rotate and be placed in position achieving better speed.

- Speed in the processes, since being an automated process it can be done for parts and mass products, or also if special developments are desired tailored to customer needs.

At Sumiparts SAS we have personalized advice from the design team and the punching machine operator, to make good use of the plans and if it is necessary to improve the arrangement of the parts that you want to punch in the metal sheet, so that the final result is optimal.

Get in touch with us by calling Pbx: +57 748 22 13, Cel phones: (+57) 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be at your disposal to assist you.

Applications and Industries

Key Industries and Applications of Sheet Metal Punching

Sheet metal punching serves as a fundamental manufacturing process across countless industrial sectors. The versatility of precision sheet metal punching makes this fabrication method indispensable for producing critical components where accuracy and reliability are paramount. From automotive to aerospace applications, sheet metal punching delivers the dimensional precision required for modern industrial manufacturing.

Automotive and Aerospace Sheet Metal Punching

In the automotive industry, sheet metal punching produces essential components including vehicle chassis, engine brackets, seat frames, and exhaust systems. The automotive sector relies heavily on CNC punching for high-volume production of consistent, reliable parts. Similarly, aerospace sheet metal punching demands even stricter tolerances for aircraft interior panels, structural supports, and instrumentation housings. The aerospace industry depends on precision punching technology to maintain safety standards while reducing component weight.

Construction and Building Applications of Metal Punching

The construction industry utilizes sheet metal punching for structural applications including steel framing systems, support brackets, and architectural elements. Construction professionals specify punched metal components for their strength and customization capabilities. HVAC systems particularly depend on custom sheet metal punching for specialized ductwork, ventilation grilles, and mounting hardware that require specific airflow patterns and installation configurations.

Electronics and Electrical Engineering Punching Solutions

The electronics manufacturing sector represents one of the most demanding applications for precision sheet metal punching. Electrical enclosures, control panels, and server racks all require precisely punched holes for components, wiring management, and ventilation systems. The telecommunications industry equally depends on sheet metal punching solutions for antenna mounts, equipment cabinets, and network infrastructure components where accuracy directly impacts performance.

This comprehensive industrial application of sheet metal punching technology demonstrates why it remains a cornerstone of modern manufacturing, providing cost-effective, high-precision solutions across diverse sectors.

Appliance and Consumer Goods

Home and commercial appliances incorporate punched metal in everything from oven cavities and refrigerator frames to washing machine drums and dishwasher chassis. The consistency and cost-effectiveness of punching make it ideal for high-volume production of consumer goods.

Specialized Industrial Applications

Beyond these core industries, sheet metal punching serves specialized sectors including medical equipment manufacturing (hospital beds, surgical instrument trays), agricultural machinery (harvester components, tractor parts), and renewable energy systems (solar panel frames, wind turbine components).

The adaptability of modern CNC punching technology allows manufacturers to create everything from simple ventilation patterns to complex geometric designs, making it one of the most versatile and widely adopted metal fabrication processes in industrial manufacturing today.