What is Satin Finish and Why It Matters

A Satin Finish is a surface treatment that produces a smooth, low-reflective sheen, striking a balance between polished and matte appearances. Unlike high-gloss finishes, a satin finish offers elegance and subtlety, making it ideal for both industrial and decorative applications.

Industries from appliances and architecture to automotive and furniture design rely on satin finishes to enhance visual appeal while providing durability and resistance to fingerprints, scratches, and minor wear.

How Satin Finish is Applied

Achieving a satin finish involves several careful steps, depending on the material:

-

Surface preparation: The substrate is cleaned and degreased to remove contaminants.

-

Sanding or abrasive brushing: Fine abrasives or brushes create a uniform, subtle texture.

-

Polishing and buffing: Controlled polishing reduces sharp reflections, creating a soft sheen.

-

Protective coating (optional): Applying clear lacquer or coating improves resistance to corrosion and wear.

💡 Tip: Using consistent strokes and applying even pressure during sanding and polishing ensures a uniform satin texture across the entire surface.

Key Benefits of Satin Finish

Manufacturers and designers choose satin finish for several reasons:

-

Elegant appearance: Smooth, low-gloss sheen enhances aesthetics.

-

Reduced glare: Less reflective than high-gloss surfaces, ideal for lighting-sensitive areas.

-

Durability: Provides protection against scratches, fingerprints, and minor abrasions.

-

Versatility: Can be applied to metals, wood, glass, and plastics.

-

Ease of maintenance: Surfaces are easier to clean and maintain over time.

These benefits make satin finishes suitable for both functional industrial components and decorative design elements.

Common Applications

Satin Finish is widely used across multiple industries:

-

Appliances and electronics: Panels, frames, and control surfaces.

-

Architectural hardware: Handles, railings, and decorative panels.

-

Automotive components: Trim, dashboard accents, and interior fixtures.

-

Furniture and interior design: Metal legs, wooden surfaces, and decorative elements.

-

Industrial equipment: Protective yet aesthetically pleasing coatings on machinery.

Its combination of visual appeal, protection, and durability makes satin finish a preferred choice for high-quality products.

Practical Tips for Achieving the Perfect Satin Finish

To maximize the quality of a satin finish:

-

Use consistent sanding strokes or brushing patterns to avoid uneven texture.

-

Select appropriate abrasive grit for the material type.

-

Apply even pressure during polishing to maintain uniformity.

-

Consider a protective clear coat to extend lifespan and maintain appearance.

-

Always work in a clean, dust-free environment to avoid imperfections.

Following these tips ensures that your satin finish is smooth, elegant, and long-lasting, meeting both aesthetic and functional requirements.

Conclusion: Why Satin Finish is Essential

A satin finish combines elegance, durability, and practicality, enhancing the look and lifespan of metal, wood, and other materials. Its low-glare, smooth surface is suitable for industrial, architectural, and decorative applications, providing both protection and visual appeal.

By following proper preparation and finishing techniques, or working with experienced professionals, you can achieve consistent, high-quality satin finishes that meet modern standards of performance and design.

Understanding the Satin Finish and Its Industrial Standard

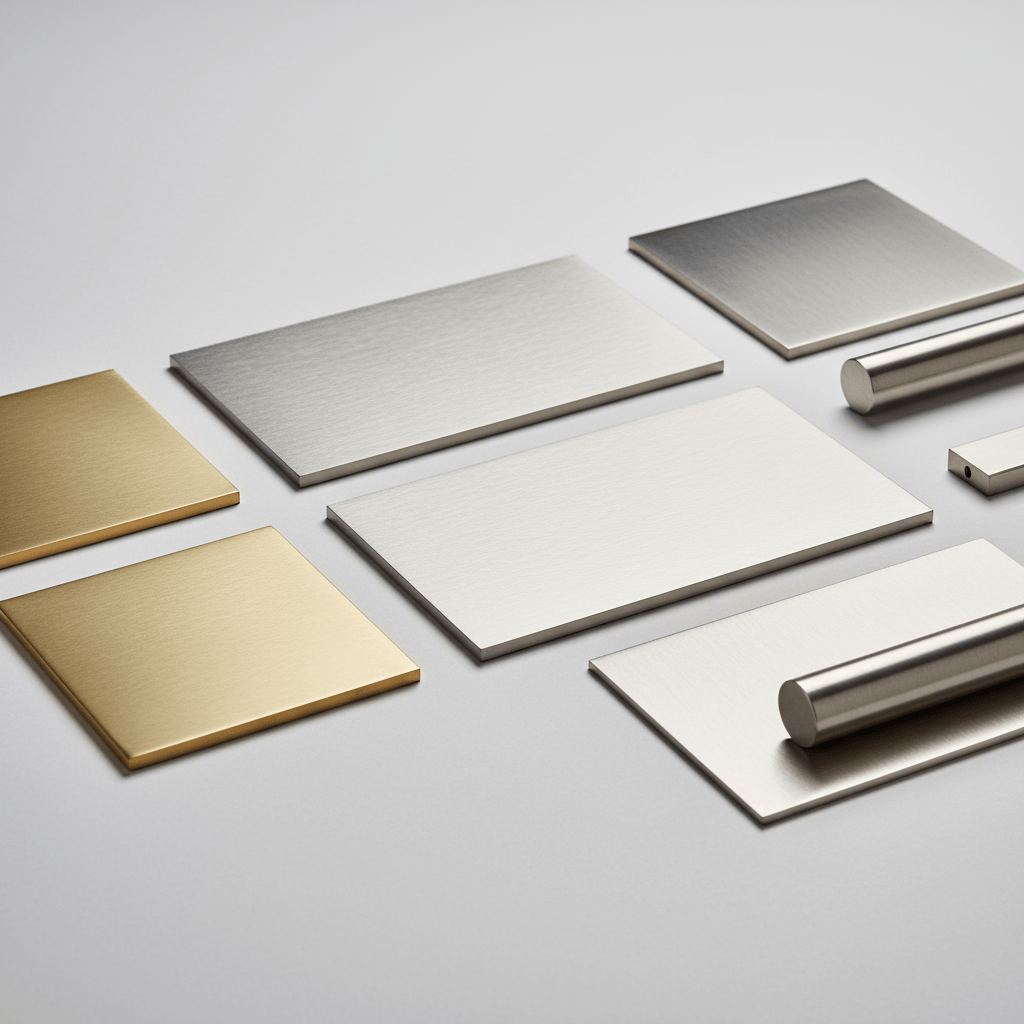

The satin finish sits right between glossy and matte, offering a balanced and elegant appearance. It provides a smooth, silky texture that enhances both the look and the feel of a surface, making it popular in decorative and architectural applications.

In interior design, this type of finish improves the appearance of walls and decorative elements by reflecting light softly and evenly. In metallurgy, it produces a refined texture without creating excessive shine, allowing materials to look polished yet understated. The result is a surface that’s easy to clean, pleasant to touch, and visually consistent — ideal for modern and functional environments.

Within the metallurgical field, specific standards have been established to ensure consistent definitions and results across different materials and coatings. These codes guide professionals in identifying and reproducing the same finish in every application:

-

US2C (602): Galvanized coating over another type of metal, typically cadmium on steel.

-

US2CD: Galvanized satin surface applied to a steel base.

-

US4 (606, 633): Brass finish on plated brass or steel.

-

US5 (609, 638): Finish applied to brass or steel surfaces.

-

US10 (612, 639): Bronze or bronze-plated steel with a satin appearance.

-

US32D (630): Finish applied to stainless steel, widely used in architectural components.

-

US26D (626, 652): Matte chrome coating used on bronze, brass, or steel.

-

US15A (620, 647): Nickel coating for brass, bronze, or steel applications.

To ensure visual consistency across different parts or materials, it’s important to check that the finish codes match before manufacturing or installation. This guarantees that every component will share the same tone, texture, and overall appearance.

If you want to know more about the Satin Surface Finishing Process, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you. we leave you some links that may be of your interes https://sumiparts.us/services/plastic-manufacturing/