What is Sandblasting and Why It Matters

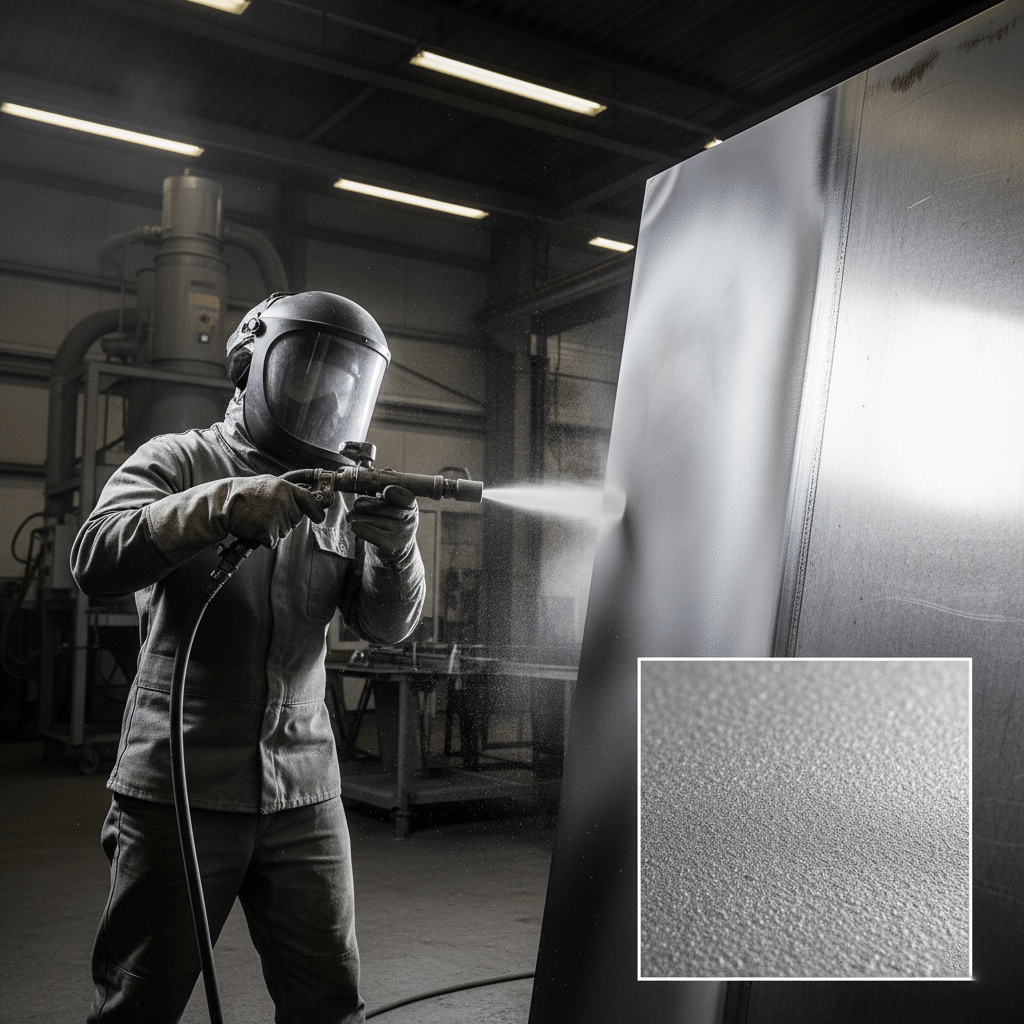

Sandblasting is a surface treatment process that uses a stream of abrasive material propelled at high speed to clean, smooth, or etch surfaces. Commonly used on metal, glass, wood, and stone, sandblasting removes rust, paint, scale, and other contaminants, leaving surfaces ready for finishing or coating.

Industries from automotive and aerospace to construction and art rely on sandblasting for both functional and aesthetic purposes. It is highly valued because it prepares surfaces efficiently while improving adhesion for paints, coatings, and protective treatments.

How the Sandblasting Process Works

The sandblasting workflow involves several carefully controlled steps to ensure optimal surface preparation and finishing:

Surface preparation: Before blasting begins, the target area is thoroughly cleaned to remove dust, grease, or loose particles. Any parts that should not be exposed are masked off with protective tape or coverings. Proper preparation ensures that the abrasive material only affects the intended surfaces and improves overall efficiency.

Selection of abrasive media: Choosing the right abrasive material is critical for achieving the desired finish. Common options include aluminum oxide, glass beads, or silicon carbide, each offering different levels of hardness, texture, and surface impact. The choice depends on the substrate material, thickness, and whether the goal is cleaning, smoothing, or creating a decorative texture.

Blasting: During the blasting stage, high-pressure air propels the chosen abrasive against the surface at controlled speeds. This process removes rust, old paint, scale, or other imperfections. Operators carefully adjust parameters like pressure, nozzle angle, and distance to prevent damage while ensuring uniform coverage across the entire surface.

Inspection and finishing: Once blasting is complete, the treated surface is inspected for uniformity, smoothness, and absence of defects. Depending on the project requirements, additional steps such as painting, coating, or polishing may be applied to enhance durability and aesthetics.

💡 Tip: Fine-tuning the abrasive size, pressure, nozzle distance, and angle allows operators to achieve precise control over texture and smoothness, making it possible to tailor the finish for both functional and decorative applications.

Benefits of Sandblasting

Manufacturers and craftsmen use sandblasting for several reasons:

Efficient cleaning: Removes rust, paint, and scale quickly.

Surface roughening: Improves adhesion for coatings and paints.

Polishing and finishing: Creates smooth, uniform surfaces or decorative textures.

Versatility: Works on metals, glass, plastics, wood, and stone.

Durability enhancement: Prepares surfaces for protective coatings that prolong lifespan.

This process is especially important in industrial maintenance, metal fabrication, and restoration projects.

Common Applications

Sandblasting finds use across multiple industries:

Automotive: Restoring car bodies, preparing surfaces for painting.

Aerospace: Cleaning and texturing aircraft components.

Construction: Preparing metal and concrete surfaces for coatings.

Industrial equipment: Removing scale or corrosion from machinery.

Art and decorative projects: Etching designs on glass, stone, or metal.

Its combination of precision, versatility, and efficiency makes it a go-to technique for professionals and hobbyists alike.

Practical Tips for Optimal Sandblasting

To achieve the best results with sandblasting, consider:

Choosing the right abrasive media based on material and desired finish.

Adjusting pressure and nozzle distance to avoid damaging the surface.

Using protective gear to ensure safety from dust and flying particles.

Working in a controlled environment to prevent contamination or overspray.

Regularly inspecting equipment to maintain consistent performance.

Following these best practices ensures surfaces are clean, smooth, and ready for finishing or coating.

Conclusion: Why is Essential

Consists of cleaning a surface by the action of a granulated abrasive expelled by compressed air through a nozzle.

Sand blast cleaning is widely used to remove rust, mill scale and any type of coating from surfaces, preparing them for the application of a coating.

Sandblasting is one that removes all corrosion, even that of the deepest craters, without significantly wearing down the material. In addition, it provides the surface with a marked finish that serves as an anchor for recoating.

Among the abrasives most frequently used in Sandblast are: silica sand, glass bead, aluminum oxide, plastic abrasive, silicon carbide, steel shot, sodium bicarbonate, corn cob, walnut shell garnet, slag coppermade.

If you want to know more about the Sandblasting, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.