Introduction

TIG Welding (Tungsten Inert Gas) is a precise welding process that uses a non-consumable tungsten electrode to produce high-quality welds. An inert gas, typically argon or helium, protects the weld area from contamination, ensuring clean and strong joints.

This process is widely used in industries requiring high precision and superior appearance, such as aerospace, automotive, food processing, and medical equipment manufacturing. TIG welding allows for control over heat input and weld bead formation, making it ideal for thin materials and critical components.

Techniques and Variations

-

Manual TIG Welding: Skilled welders control the torch and filler rod for intricate joints.

-

Automated TIG Welding: CNC-controlled systems perform repeatable, consistent welds for high-volume production.

-

Pulsed TIG Welding: Alternates between high and low current to control heat input and reduce distortion.

-

AC/DC TIG Welding: AC is typically used for aluminum and magnesium, while DC is preferred for steels and stainless steels.

Operators can adjust current, travel speed, and torch angle to achieve the optimal weld for each material and application.

Materials Compatible with This Process

-

Stainless Steel: Excellent for corrosion-resistant structures and decorative elements.

-

Aluminum and Magnesium: Pulsed AC welding prevents warping and ensures clean bead formation.

-

Carbon Steel: Ideal for structural and industrial components.

-

Copper and Copper Alloys: Requires careful heat control to prevent oxidation and porosity.

Selecting the right filler rod and shielding gas ensures strong, clean welds with minimal defects.

Preparation and Safety Practices

-

Clean and degrease surfaces to remove contaminants.

-

Ensure proper fit-up and alignment of components.

-

Verify gas flow and regulator settings.

-

Use protective gear, including gloves, helmet, and protective clothing.

Maintaining a stable arc and controlling the heat input helps avoid distortion, burn-through, and weld defects. These precautions are critical for both manual and automated TIG welding.

Advantages and Industrial Applications

-

High precision: Produces clean, narrow welds suitable for thin materials.

-

Aesthetic welds: Minimal spatter and smooth, uniform beads.

-

Versatility: Can join a wide range of metals and alloys.

-

Control over heat input: Reduces distortion and maintains material properties.

Typical applications include aerospace components, piping systems, medical instruments, food processing equipment, and high-quality decorative metalwork. TIG welding is often chosen when appearance, corrosion resistance, and structural integrity are critical.

Tips for Optimal TIG Welding

To achieve the best results:

-

Use the correct electrode size and type for each material.

-

Adjust amperage to match material thickness.

-

Maintain proper torch angle and distance.

-

Control filler material feed to avoid inclusions or porosity.

-

Inspect welds visually and with non-destructive testing (NDT) for critical components.

Following these guidelines ensures consistent, strong, and visually appealing welds while maximizing efficiency and safety.

Emerging Trends in TIG Welding

Modern TIG welding incorporates robotics, CNC automation, and pulse-control systems. These technologies allow:

-

Faster production cycles with consistent quality

-

Reduced human error and fatigue

-

Ability to weld complex geometries and thin materials

-

Integration with other fabrication processes for high-volume manufacturing

TIG Welding remains a cornerstone of precision metal joining, providing a combination of strength, appearance, and versatility that is hard to match with other welding methods.

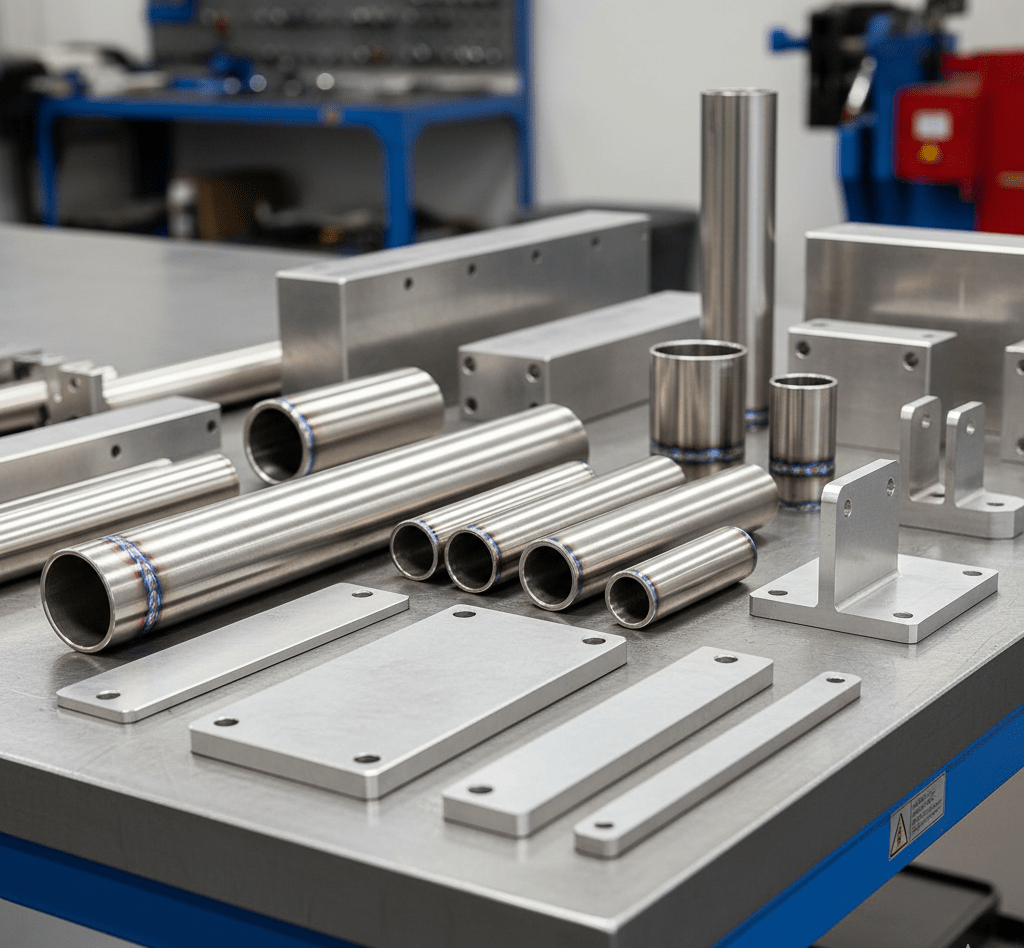

Welding of the tubes to the plates of the heat exchangers.

Differences between MIG / MAG welding and TIG welding

The main difference between MIG / MAG welding and TIG welding is that, in the first, the electrode acts as a filler for welding and is consumed in the process, while in the second, it does not change.

In addition, TIG is generally considered more difficult to do than the other two as a result of tolerances between the electrode, workpiece, and filler rod. Its uses and applications, as already mentioned before, are quite different, being the MIG and MAG types the most used in the industry in general.

If you want to know more about the TIG Welding, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.