Introduction to Sheet Metal Bending

Sheet Metal Bending is a fundamental forming process in metal fabrication, used to create angles, curves, and complex shapes from flat sheets. By applying force along a straight axis, the material is plastically deformed without compromising structural integrity.

This process is essential in industries such as automotive, aerospace, electronics, construction, and industrial machinery. Sheet Metal Bending allows manufacturers to produce consistent, precise, and high-quality components, reducing the need for additional assembly or finishing.

Common Bending Techniques

Several techniques are commonly used to achieve accurate and reliable bends:

-

V-Bending: The sheet is pressed into a V-shaped die using a punch, producing consistent angles.

-

Air Bending: The sheet is bent above the die, allowing flexibility in angles with fewer die changes.

-

Bottoming: The sheet is pressed fully into the die for maximum accuracy and sharper bends.

-

Roll Bending: Produces curves or cylindrical shapes by passing the sheet through rollers.

-

Edge Bending: Creates small flanges or folds along sheet edges for strength or assembly features.

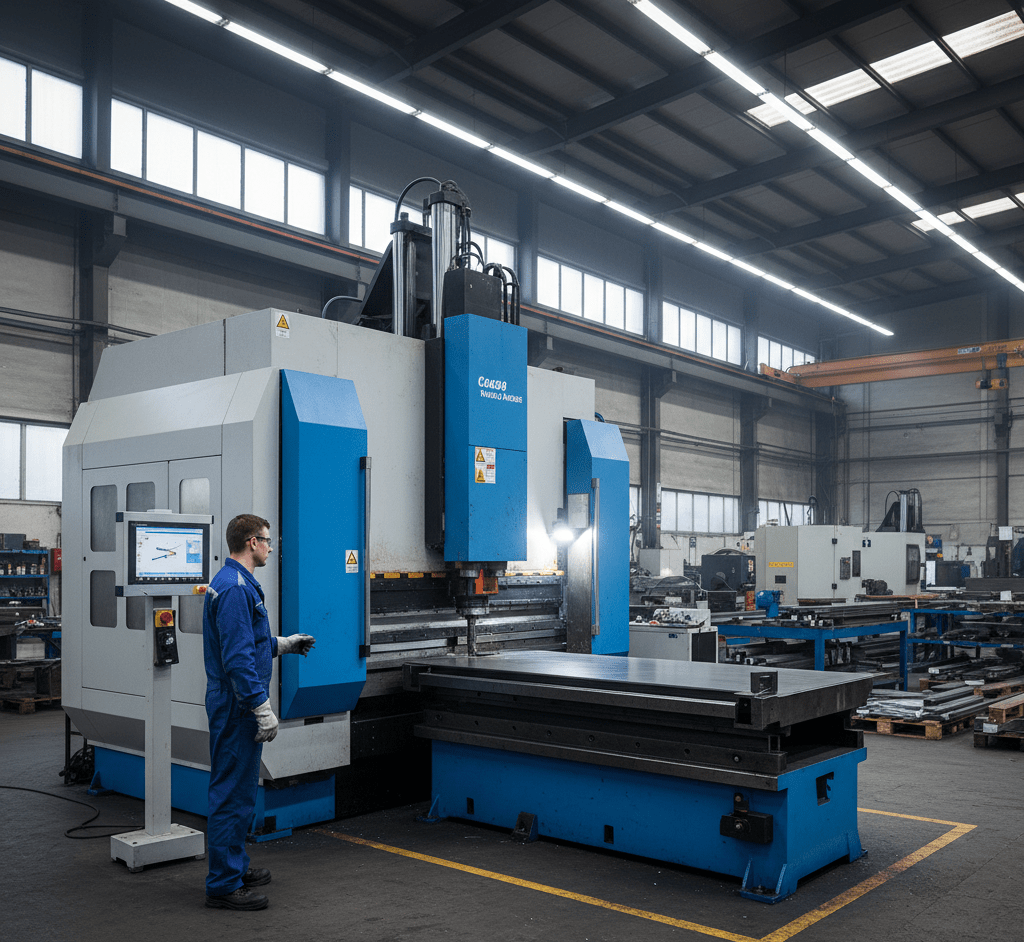

Modern CNC press brakes and automated bending systems allow repeatable and precise bends even in complex geometries.

Material Considerations

Sheet Metal Bending works with a wide variety of materials:

-

Metals: steel, stainless steel, aluminum, brass, copper

-

Thicknesses: from thin foils to thick plates, depending on tooling and machine capacity

-

Surface finish: smooth, coated, or pre-treated sheets

Factors such as material thickness, yield strength, and grain direction influence the bending process. Adjusting punch/die selection, press force, and bending speed ensures accurate angles without cracking or surface defects.

Preparation and Best Practices

Proper preparation is crucial to successful bending operations:

-

Inspect sheets for flatness, surface defects, or contaminations

-

Determine correct bend allowance to compensate for material spring-back

-

Ensure proper alignment and clamping in the press brake or bending machine

-

Verify tooling is appropriate for material type and thickness

Following these steps minimizes material waste, reduces rework, and improves consistency across production batches.

Advantages and Industrial Applications

Sheet Metal Bending offers several key advantages:

-

Precision: Consistent, repeatable bends for high-quality assemblies

-

Versatility: Works for a variety of metals, thicknesses, and shapes

-

Efficiency: Reduces material handling and additional fabrication steps

-

Structural integrity: Bends maintain material strength with minimal defects

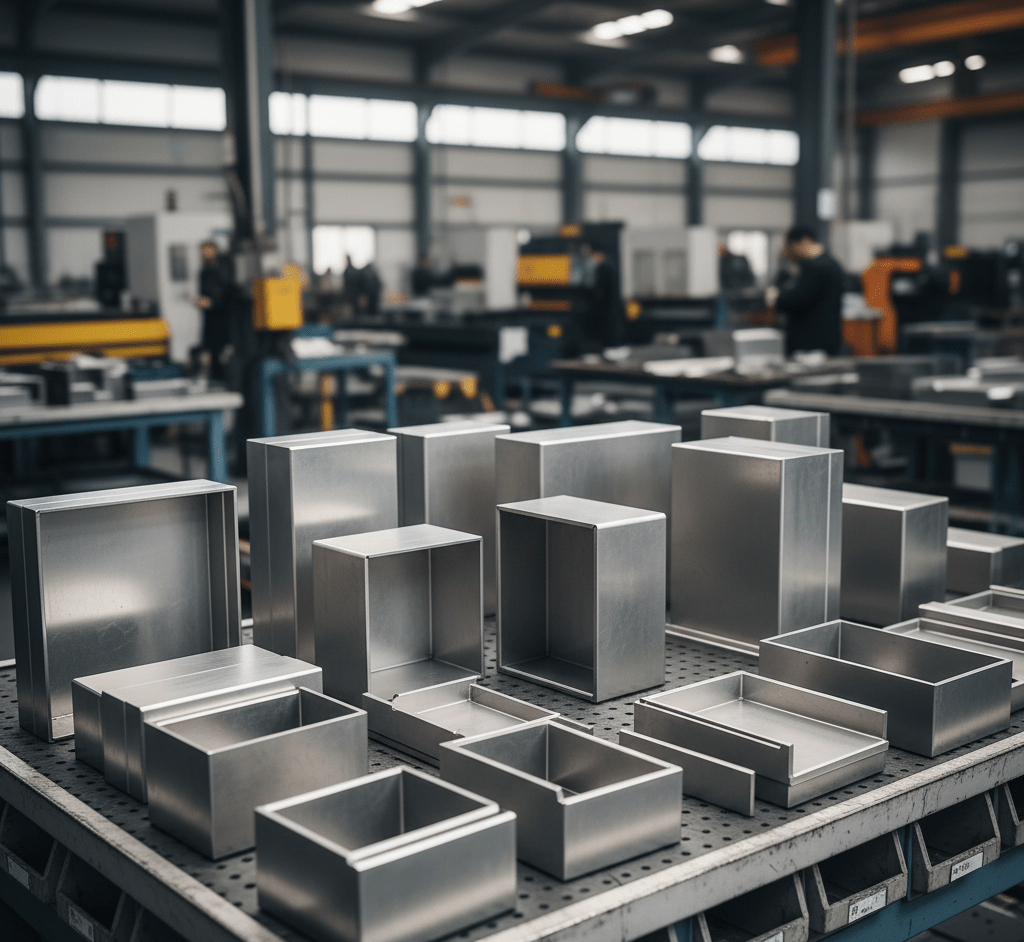

Applications include automotive panels, HVAC components, enclosures, brackets, machinery parts, and architectural elements. Sheet Metal Bending can also be combined with cutting, punching, or welding to create fully functional assemblies.

Tips for Optimal Performance

-

Use proper bend radius to avoid cracking, especially in high-strength alloys

-

Monitor tooling wear and replace punches/dies as needed

-

Maintain consistent press speed and pressure for uniform results

-

Consider protective coatings or lubrication to prevent surface damage

-

Simulate complex bends digitally before production to avoid errors

Implementing these practices ensures high-quality parts, extended tool life, and efficient production.

Emerging Trends in Sheet Metal Bending

New technologies are rapidly transforming sheet metal bending operations, allowing manufacturers to produce high-quality parts more efficiently and accurately than ever before.

-

CNC-controlled press brakes: These machines automate bending cycles, providing precise, repeatable results with minimal human intervention. By programming angles, bend sequences, and material specifications, operators can handle complex parts consistently, reducing errors and waste.

-

Robotic bending cells: Robotic arms equipped with bending tools can manipulate large sheets or perform multiple bends in sequence. This is particularly useful for high-volume production or intricate components that would be challenging to form manually. Robotics also improve workplace safety by reducing the need for operators to handle heavy or sharp materials.

-

Advanced simulation software: Modern CAD/CAM software allows engineers to simulate bending processes before production. The software predicts spring-back, stress points, and material behavior, enabling adjustments to tooling, bend allowance, and sequences. This reduces trial-and-error, shortens lead times, and ensures parts meet tight tolerances.

-

Hybrid forming techniques: Combining sheet metal bending with other forming methods, such as rolling, stretching, or hydroforming, allows for more complex geometries and functional features. These hybrid techniques expand the design possibilities, enabling lightweight, structurally strong, and aesthetically appealing components.

Together, these advancements provide manufacturers with higher precision, faster production, and greater flexibility. They allow for the efficient creation of complex assemblies while maintaining consistent quality, making sheet metal bending a cornerstone of modern metal fabrication. Companies can now meet diverse industrial demands—from automotive panels to custom architectural elements—while reducing costs and material waste.

If you want to know more about the SHEET METAL BENDING, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.