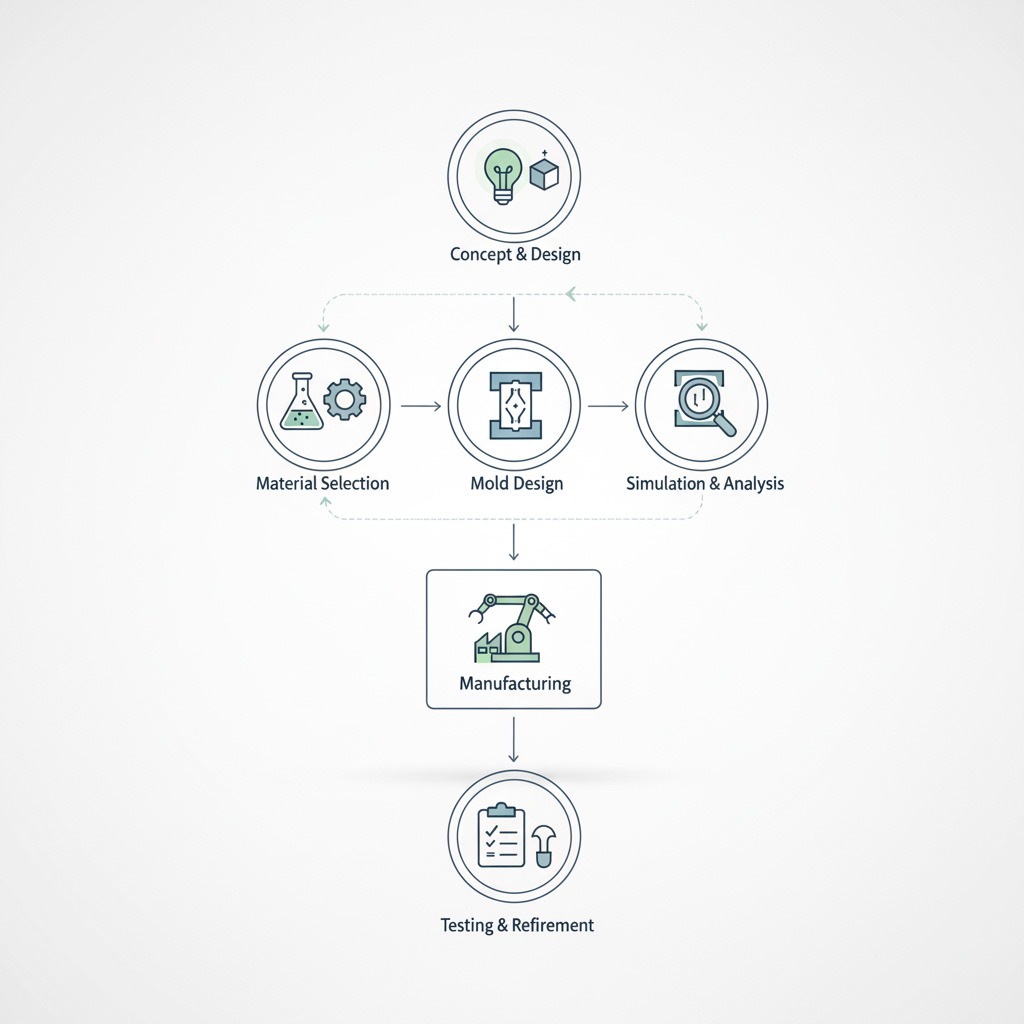

How Plastic Injection Mold Design Shapes Cycle Time, Quality, and Production Costs

Plastic Injection Mold Design plays a central role in modern manufacturing by determining the efficiency, quality, and economic viability of every molded component. Although materials, machines, and processing parameters influence results, the mold itself is the heart of the operation. A well-engineered mold can drastically reduce cycle time, eliminate defects, improve dimensional stability, and lower overall production costs.

In high-volume industries—such as automotive, electronics, medical devices, construction, and consumer goods—the ability to design molds that ensure repeatability and minimal scrap is essential. Plastic Injection Mold Design is no longer a simple machining task; it involves engineering analysis, simulation, thermal optimization, and precision manufacturing.

Why Plastic Injection Mold Design Directly Impacts Cycle Time

Cycle time is the most important economic variable in injection molding. A mold that reduces the cycle by even one second can result in thousands of dollars in savings per year.

Several design factors influence cycle time:

1. Cooling system efficiency

More than 70% of cycle time is cooling. An optimized cooling layout ensures uniform heat dissipation, reducing warpage and allowing shorter cycles. Techniques such as conformal cooling channels produced through additive manufacturing offer superior efficiency compared to traditional drilling.

2. Gate and runner design

Direct gate locations, balanced runners, and proper flow channels reduce injection pressure, avoid short shots, and stabilize filling. Mold flow simulations help visualize material behavior to optimize these features.

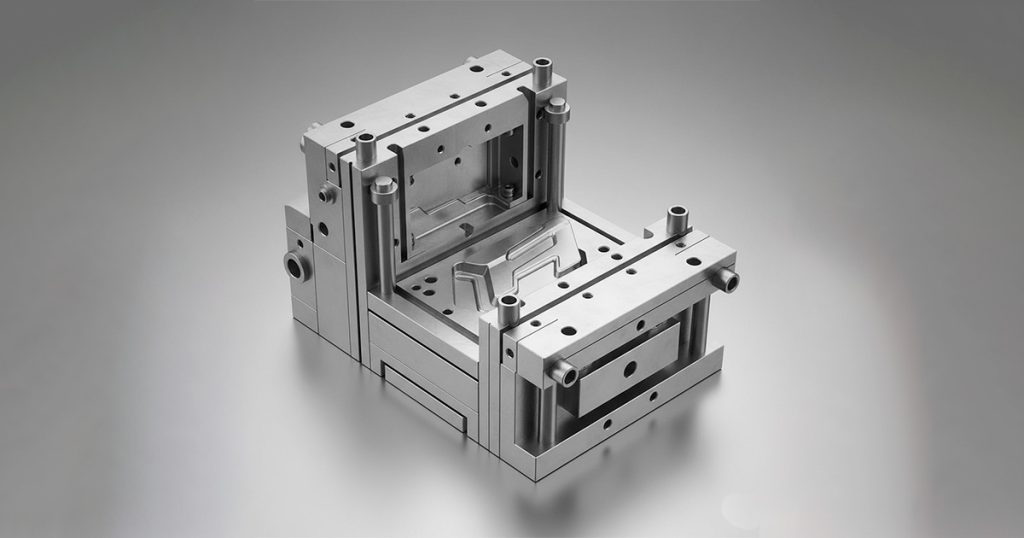

3. Steel selection and thermal conductivity

High-conductivity tool steels accelerate heat transfer, shortening both cooling and total cycle times. For highly demanding applications, alloys with superior thermal properties can significantly improve productivity.

4. Ejection system engineering

Smooth, even, and controlled ejection prevents part deformation and reduces delays. Air assist, pneumatic systems, and spring-loaded ejectors are commonly used to enhance stability.

When these elements are integrated correctly within Plastic Injection Mold Design, cycle time becomes predictable, repeatable, and measurably lower—allowing manufacturers to increase output without additional equipment.

How Mold Design Determines Product Quality

The quality of any injection molded part is rooted in the design of the mold. Even the best processing parameters cannot compensate for a poorly engineered tool.

Dimensional Precision

Proper cavity design, shrinkage compensation, and balanced filling ensure that parts meet exact tolerances. High-precision machining combined with tool steel stability maintains repeatable accuracy.

Defect Prevention

Common defects—such as sink marks, flow lines, flash, warpage, weld lines, and voids—are largely influenced by mold geometry, cooling distribution, and gating strategy. Good design minimizes these issues before they arise.

Surface Finish and Aesthetics

Polished cavities, controlled venting, and balanced packing pressure contribute to flawless surfaces. For high-end consumer products or medical components, surface detail is essential.

Material Behavior Control

Plastic Injection Mold Design considers viscosity, shrinkage, crystallinity, and fiber reinforcement orientation. This ensures the final part maintains mechanical strength, impact resistance, and stability over time.

A well-designed mold elevates the final product from “functional” to “high-performance,” ensuring consistent quality throughout the production life of the tool.

Reducing Production Costs Through Better Mold Design

Although mold manufacturing represents a significant initial investment, great design results in lower long-term costs. A poorly built mold increases downtime, scrap rates, and maintenance expenses.

Improved material use

Optimized runners, thinner walls, and balanced cavities reduce material waste, which is crucial when working with engineering-grade resins.

Lower scrap rates

Defects cost money. A stable mold drastically decreases rejected parts, improving overall equipment efficiency.

Less machine wear

When injection pressure, flow, and temperatures are stabilized, machines experience less mechanical stress, reducing long-term maintenance costs.

Faster setup and changeover

A modular, well-engineered mold reduces alignment time, improves repeatability, and speeds up mold changes, contributing to lean manufacturing practices.

Plastic Injection Mold Design is, therefore, a strategic investment that determines the profitability of every production run.

Engineering Tools That Enhance Mold Performance

Modern mold design depends heavily on advanced engineering tools that ensure predictable and optimized results.

Software like Moldflow, Moldex3D, and SolidWorks Plastics allows engineers to predict filling patterns, air traps, weld lines, cooling efficiency, and warpage before machining begins.

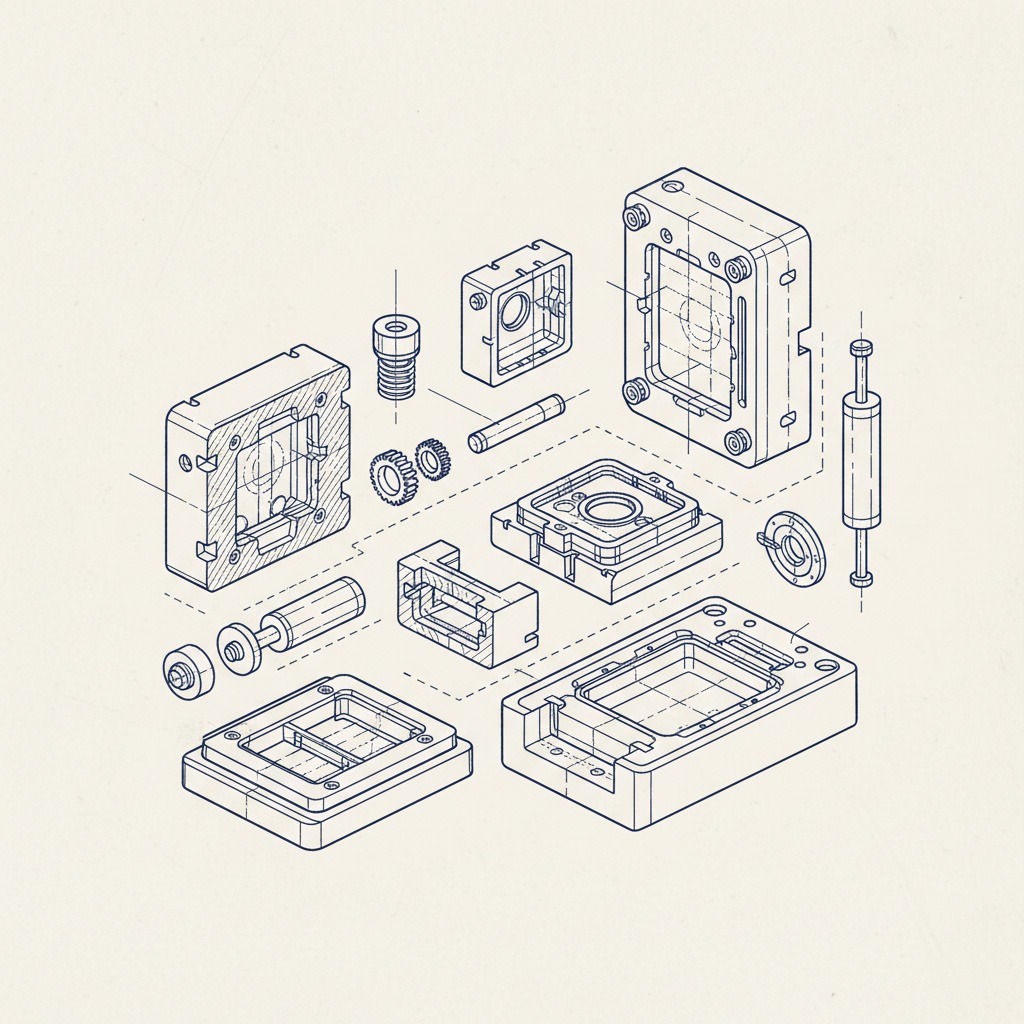

CAD/CAM Integration

High-precision machining is only possible when CAD geometry is flawlessly translated into toolpaths. CAM software ensures accuracy in cavity machining, electrodes, and complex contouring.

Finite Element Analysis (FEA)

Used to analyze mold structure, thermal stress, and deformation—guaranteeing long tool life and stable performance.

Digital Twins

Increasingly, molds are paired with real-time digital twins that monitor temperature, pressure, and cycle time during production.

These tools ensure that the Plastic Injection Mold Design process is both predictive and data-driven.

Conclusion

Plastic Injection Mold Design defines the performance, quality, and profitability of any injection molding operation. By optimizing cooling, gating, materials, structural engineering, and simulation, companies can produce components faster, more consistently, and at a lower cost. As the industry continues to evolve, high-precision mold design remains the foundation of competitive manufacturing.

Got questions? Go to our Contact Us page and send us a message — we’re here to help.