Understanding Plasma Cutting Technology

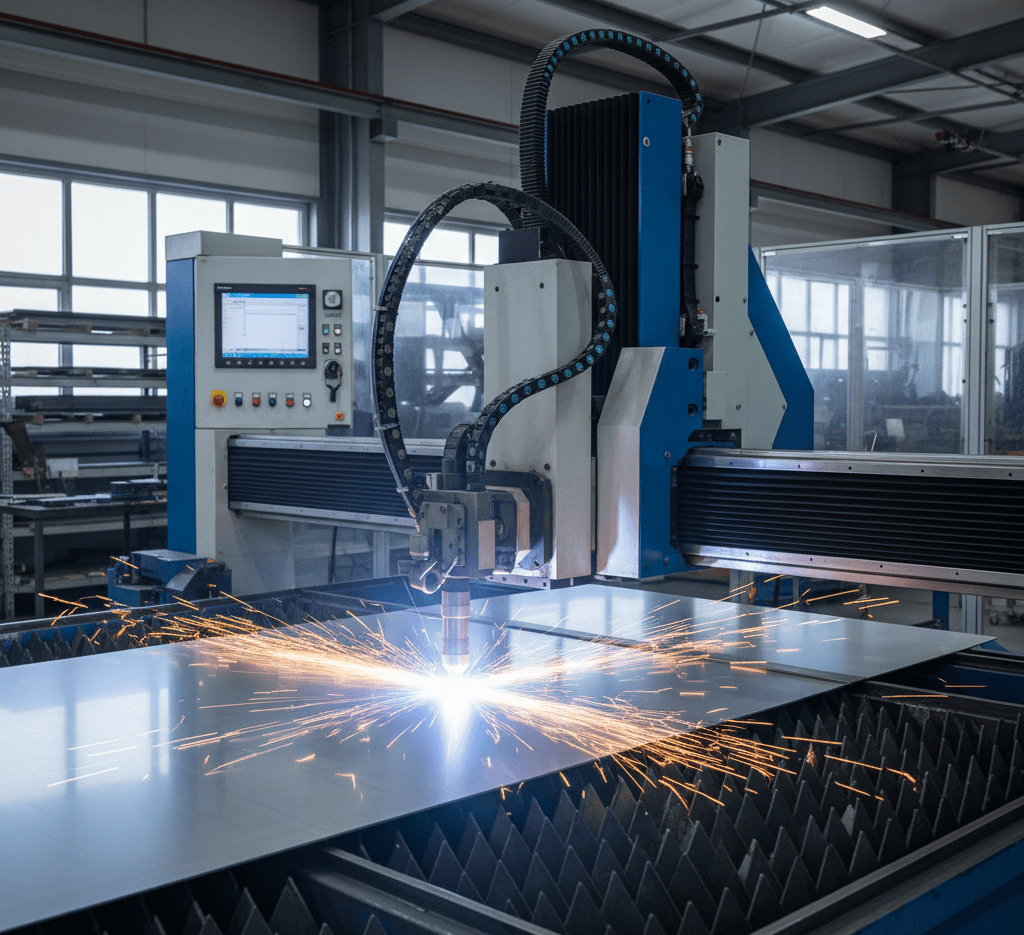

The plasma cutting process uses a high-energy stream of ionized gas to slice through electrically conductive metals. Unlike mechanical cutting, this method is non-contact, allowing for faster and more precise cuts on materials such as stainless steel, aluminum, copper, and brass.

Modern plasma technology often incorporates CNC systems, enabling the production of complex shapes with consistent quality. This makes it ideal for applications where precision, speed, and repeatability are essential.

Types of Plasma Cutting Systems

Not all plasma setups are the same. Understanding the differences helps manufacturers choose the right method for each project:

-

Manual plasma torches: Suitable for small-scale or custom cuts where flexibility is required.

-

CNC-controlled plasma systems: Automated machines provide high precision and allow complex or repetitive cuts with minimal human intervention.

-

High-definition plasma cutting: Delivers cleaner edges and better surface quality on thicker metals, reducing finishing work.

Each system has unique advantages depending on material thickness, complexity, and production volume.

Advantages Over Traditional Cutting Methods

Compared to traditional cutting methods, this metal cutting technique offers several benefits:

-

Speed: Cuts thick metals more quickly than oxy-fuel or mechanical methods.

-

Precision: Produces accurate, clean edges, minimizing post-processing.

-

Versatility: Works on a wide range of conductive metals and thicknesses.

-

Efficiency: Reduces material waste and energy usage.

-

Automation-friendly: Integrates easily with CNC machines for repeated or complex patterns.

These benefits make the plasma cutting process an essential tool in industrial fabrication and custom metal projects.

Industrial Applications

The versatility of this method allows it to be applied across multiple sectors:

-

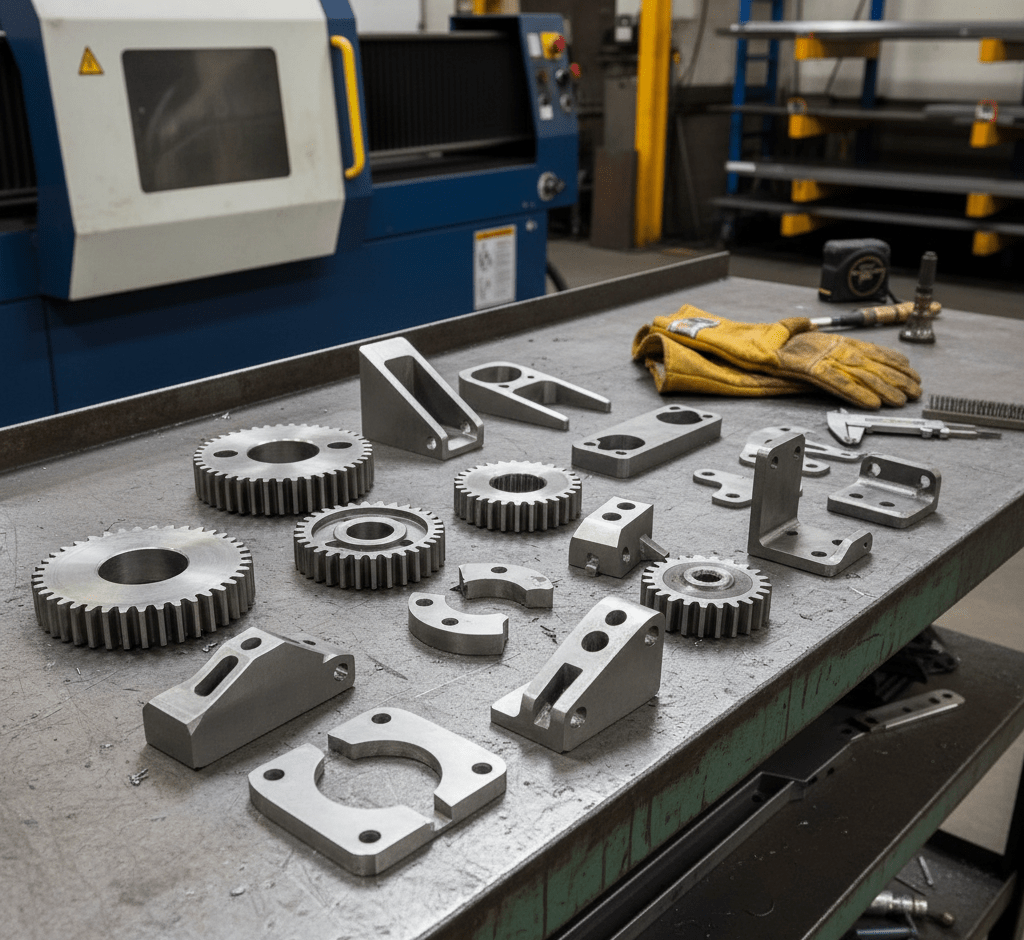

Automotive and aerospace: Cutting chassis, brackets, panels, and structural components.

-

Shipbuilding and heavy machinery: Fabrication of hull plates, frames, and specialized parts.

-

Construction: Structural steel beams, metal frameworks, and reinforcements.

-

Custom metalwork: Architectural elements, decorative panels, and signage.

By using plasma technology, manufacturers achieve faster turnaround, consistent results, and reduced finishing work.

Best Practices for Optimal Cutting

To ensure high-quality results, consider these recommendations for plasma cutting operations:

-

Select the appropriate plasma gas for each metal type to maximize cut quality.

-

Adjust torch height, travel speed, and amperage to minimize dross and warping.

-

Maintain equipment regularly, including consumables such as nozzles and electrodes.

-

Utilize CNC programming for intricate or repetitive shapes to improve accuracy.

-

Follow safety protocols, including grounding, protective gear, and proper ventilation.

Proper setup and maintenance ensure clean, precise cuts with consistent dimensions across all projects.

.

Maintenance and Efficiency Tips for Plasma Cutting

To ensure long-term performance and consistent results in plasma cutting, regular maintenance and careful setup are essential. Some practical tips include:

-

Inspect consumables regularly: Nozzles, electrodes, and shields wear over time. Replacing them promptly ensures clean, precise cuts.

-

Keep workpieces clean: Remove rust, oil, or debris before cutting to avoid inconsistent results and reduce wear on the torch.

-

Calibrate cutting parameters: Adjust gas type, pressure, and amperage according to material type and thickness for optimal edge quality.

-

Optimize torch movement: Use smooth, consistent motion and avoid abrupt direction changes to minimize dross and ensure uniform cuts.

-

Plan material layout efficiently: Nesting parts carefully reduces waste and improves production speed.

Maintenance and Efficiency Tips for Plasma Cutting

To ensure long-term performance and consistent results in plasma cutting, regular maintenance and careful setup are essential. Some practical tips include:

-

Inspect consumables regularly: Nozzles, electrodes, and shields wear over time. Replacing them promptly ensures clean, precise cuts.

-

Keep workpieces clean: Remove rust, oil, or debris before cutting to avoid inconsistent results and reduce wear on the torch.

-

Calibrate cutting parameters: Adjust gas type, pressure, and amperage according to material type and thickness for optimal edge quality.

-

Optimize torch movement: Use smooth, consistent motion and avoid abrupt direction changes to minimize dross and ensure uniform cuts.

-

Plan material layout efficiently: Nesting parts carefully reduces waste and improves production speed.

Conclusion

The plasma cutting process is a fast, accurate, and flexible method for shaping electrically conductive metals. Its advantages — including speed, precision, efficiency, and automation compatibility — make it indispensable for industrial, construction, and custom fabrication projects.

By leveraging CNC technology, proper settings, and regular maintenance, manufacturers can achieve high-quality, repeatable results while minimizing material waste and post-processing efforts. This makes plasma technology a reliable solution for modern metalworking needs.

If you want to know more about the Plasma Cutting, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you. We leave you some articles that may be of interest to you https://sumiparts.us/services/plastic-injection-design-service/