What is Nitrile Rubber and How It’s Used?

Nitrile Rubber, also known as NBR, is a synthetic elastomer made from the copolymerization of acrylonitrile and butadiene. This material is highly valued for its excellent resistance to oils, fuels, chemicals, and abrasion, making it ideal for industrial, automotive, and mechanical applications.

At SUMIPARTS SAS, we specialize in transforming Nitrile Rubber through advanced vulcanizing and extrusion processes. Our capabilities allow the production of high-quality custom components, ensuring dimensional precision, durability, and performance under extreme conditions.

Industrial Applications of Nitrile Rubber:

Automotive industry: seals, gaskets, O-rings, fuel hoses, and vibration dampers.

Industrial machinery: conveyor belts, hydraulic hoses, mechanical buffers, and flexible connectors.

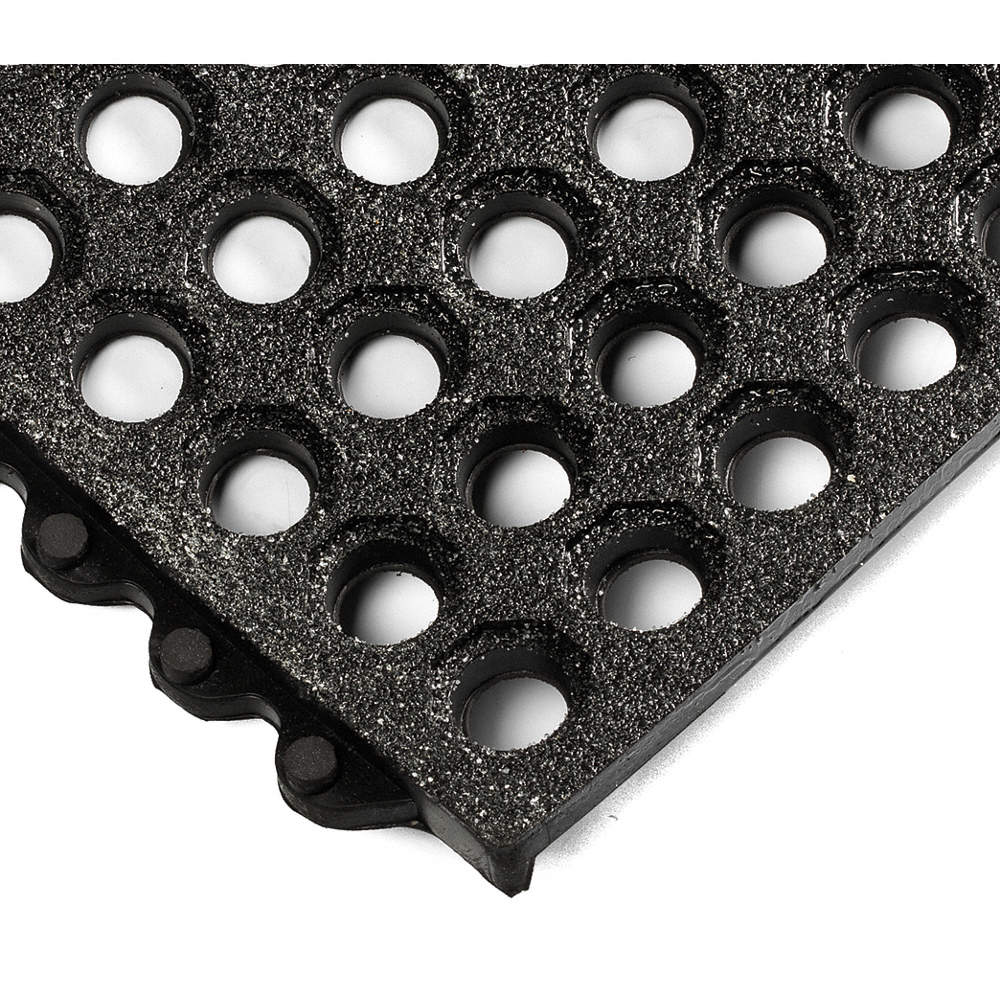

Construction: expansion joints, anti-slip pads, and protective insulation.

Consumer and specialized products: gloves, protective components, and molded parts resistant to oils and chemicals.

Advantages of Nitrile Rubber:

- Excellent chemical, oil, and fuel resistance:

Nitrile Rubber is widely recognized for its outstanding resistance to oils, fuels, and a broad range of chemicals. This property makes it an ideal material for automotive seals, gaskets, hoses, and industrial components exposed to harsh fluids or corrosive environments. - High abrasion and mechanical wear resistance:

Components made from Nitrile Rubber exhibit superior durability and wear resistance. Its ability to withstand repeated friction, stress, and mechanical loads ensures long-lasting performance in demanding industrial applications, including conveyor systems, vibration dampers, and hydraulic assemblies. - Durable under moderate temperature variations and dynamic stress:

Nitrile Rubber maintains its elasticity and functional integrity even under fluctuating temperatures and continuous mechanical stress. This stability allows it to perform reliably in automotive, industrial, and construction environments where dynamic conditions are common. - Easy to process through vulcanization and extrusion techniques:

Nitrile Rubber can be efficiently shaped using advanced vulcanization and extrusion processes. These methods allow for precise manufacturing of complex geometries, high-volume production, and consistent quality across all NBR components. - Cost-effective compared to other specialty synthetic rubbers:

The combination of performance, chemical resistance, and mechanical durability makes Nitrile Rubber a highly cost-effective solution. It provides the advantages of specialty synthetic rubbers at a lower production cost, making it ideal for large-scale industrial and automotive applications.

Manufacturing and Customization of Nitrile Rubber (NBR)

At SUMIPARTS SAS, Nitrile Rubber (NBR) undergoes advanced industrial processes specifically designed to deliver precision, consistency, and high scalability for industrial and automotive applications. Our extensive expertise allows us to transform raw NBR material into high-quality, durable components through vulcanization, extrusion, and molding techniques, ensuring each product meets the strictest performance and safety standards.

Our team works closely with clients to define the optimal grade, hardness, and geometry for each project, tailoring every NBR part to its intended function. From complex seals, gaskets, and O-rings to hoses, vibration-damping components, and custom industrial parts, SUMIPARTS SAS combines material science with state-of-the-art machinery and precision tooling to create reliable, high-performance products.

The advanced manufacturing processes we employ allow us to maintain high-volume production while ensuring consistent quality in every batch. This attention to detail guarantees that Nitrile Rubber components retain their elasticity, chemical resistance, and mechanical durability, even under extreme operating conditions or prolonged use.

By leveraging innovative production techniques and close collaboration with our clients, SUMIPARTS SAS provides customized NBR solutions across a wide range of industries. These include automotive, industrial machinery, construction, hydraulic systems, and specialized equipment, where performance, safety, and reliability are critical. Our focus on precision, customization, and efficiency ensures that every Nitrile Rubber component we manufacture not only meets but exceeds client expectations, offering long-term value and performance in demanding industrial environments.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click here , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.