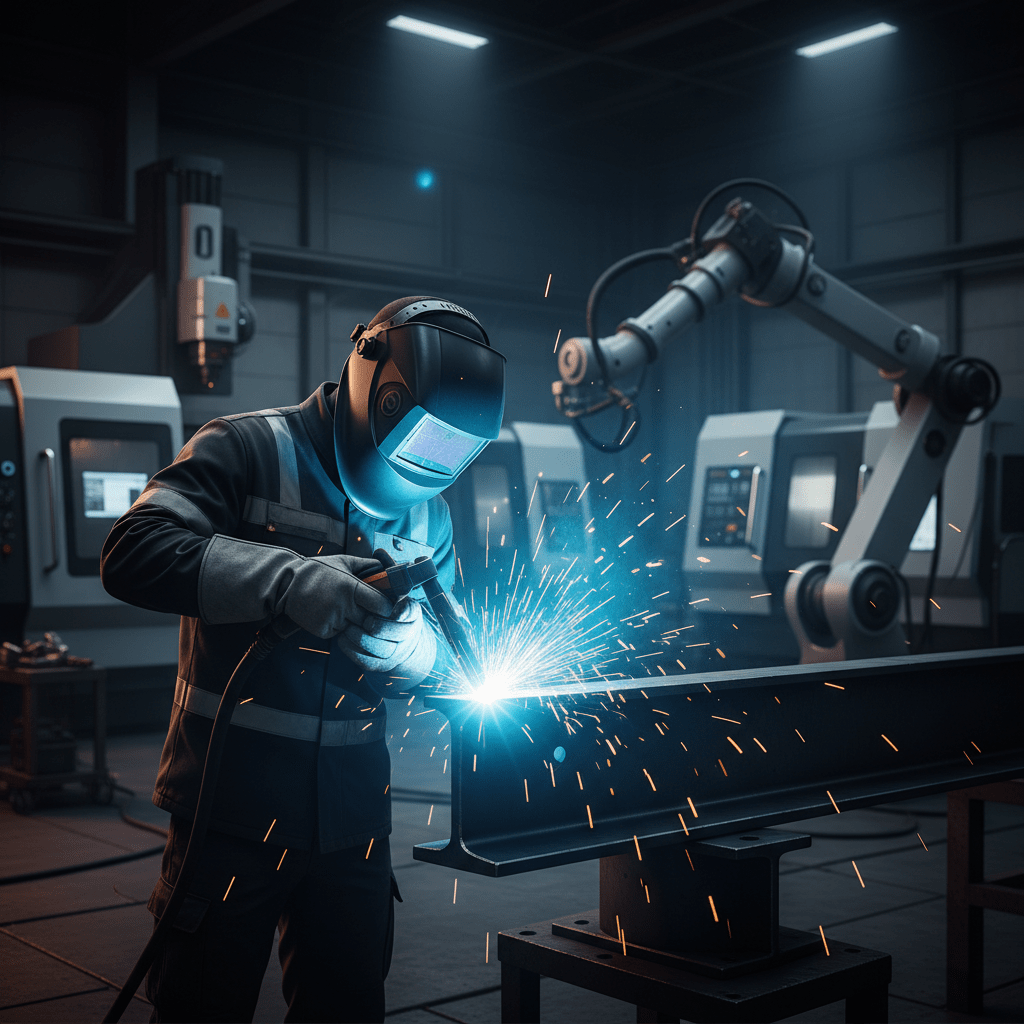

MIG/MAG Welding: Advanced Technology for Industrial Strength and Precision

MIG/MAG Welding (Metal Inert Gas / Metal Active Gas) is one of the most widely used and efficient arc welding processes in modern industry. Known for its precision, speed, and versatility, MIG/MAG Welding allows manufacturers to achieve strong, clean, and repeatable welds on a variety of metals, including carbon steel, stainless steel, and aluminum.

At Sumiparts SAS, we provide professional MIG/MAG Welding services designed to meet the needs of today’s industrial sectors — from construction and automotive to machinery and metal fabrication. Our advanced welding equipment, coupled with digital control systems, enables precise heat control, minimal deformation, and consistent penetration in every weld.

The MIG Welding process uses an inert shielding gas such as argon or helium to protect the molten pool from oxidation, resulting in clean and visually appealing joints. On the other hand, MAG Welding employs active gases like CO₂ or gas mixtures to improve penetration and productivity. The combination of these techniques — collectively referred to as MIG/MAG Welding — gives our technicians the flexibility to select the optimal parameters for each material and thickness.

Typical applications of MIG/MAG Welding

The field of application for this welding process is remarkably extensive, making it one of the most commonly used techniques in modern industry. Its versatility and adaptability to different materials and thicknesses allow it to be implemented across multiple sectors that demand strong, precise, and durable joints.

In vehicle manufacturing and mechanical repair workshops, it is used to join structural frames, chassis, and exhaust systems, providing both strength and visual quality to the finished product. In the production of pipelines, this process ensures leak-free joints and excellent resistance to pressure and temperature variations, essential for energy and fluid transport systems.

The method is also highly relevant in the naval and automotive industries, where the need for consistent and reliable welds is crucial for safety and performance. Additionally, it plays a vital role in the sheet metal processing industry, enabling efficient fabrication of enclosures, supports, and metal structures. Overall, its wide applicability, combined with speed and efficiency, has made it a cornerstone technology in industrial manufacturing and maintenance operations.

Differences between MIG / MAG welding and TIG welding

The main difference between MIG / MAG welding and TIG welding is that, in the first, the electrode acts as a filler for welding and is consumed in the process, while in the second, it does not change.

In addition, TIG is generally considered more difficult to do than the other two as a result of tolerances between the electrode, workpiece, and filler rod. Its uses and applications, as already mentioned before, are quite different, being the MIG and MAG types the most used in the industry in general.

If you want to know more about the MIG/MAG Welding, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.

Comparison Between MIG, TIG, and Stick Welding

In the industrial world, welding is one of the most critical processes for joining metallic components with structural integrity and long-term performance. Among the most common techniques are MIG, TIG, and Stick welding — each with unique characteristics that make them ideal for different applications, materials, and production environments.

At Sumiparts SAS, we apply these processes according to the technical requirements of every project, ensuring durability, precision, and consistency in each welded joint.

MIG Welding (Metal Inert Gas)

MIG welding, also known as Gas Metal Arc Welding (GMAW), uses a continuously fed wire electrode and a shielding gas to protect the weld from contamination.

It is highly productive, making it suitable for industrial-scale manufacturing, automotive components, and metal structures that require speed and repeatability.

Advantages:

High welding speed and deposition rate.

Easy to automate and integrate into robotic systems.

Minimal post-weld cleaning.

Limitations:

Requires a stable environment — not ideal for outdoor or windy conditions.

Equipment is more complex compared to other methods.