Metallic Structures - Precision Engineering and Design

At SUMIPARTS, every metallic structure begins with a rigorous engineering process focused on precision, performance, and durability. Our design phase integrates Computer-Aided Design (CAD) modeling with advanced Finite Element Analysis (FEA) to guarantee optimal mechanical behavior and maximum efficiency in real-world conditions.

Each structure is meticulously engineered to meet specific client requirements, whether for heavy-duty industrial frameworks, support systems, or custom machinery components. By combining simulation tools and material science expertise, our engineers optimize every detail — from geometry and wall thickness to load distribution — achieving a perfect balance between strength, weight, and manufacturability.

Through digital simulations, we can predict and evaluate stress concentrations, vibrations, temperature effects, and fatigue performance before production begins. This proactive approach allows us to design metallic structures that withstand the most demanding operational environments while reducing production costs and lead times.

Our commitment to precision engineering ensures that every project delivers superior structural integrity, enhanced longevity, and consistent performance — reflecting SUMIPARTS’ dedication to innovation, reliability, and industrial excellence.

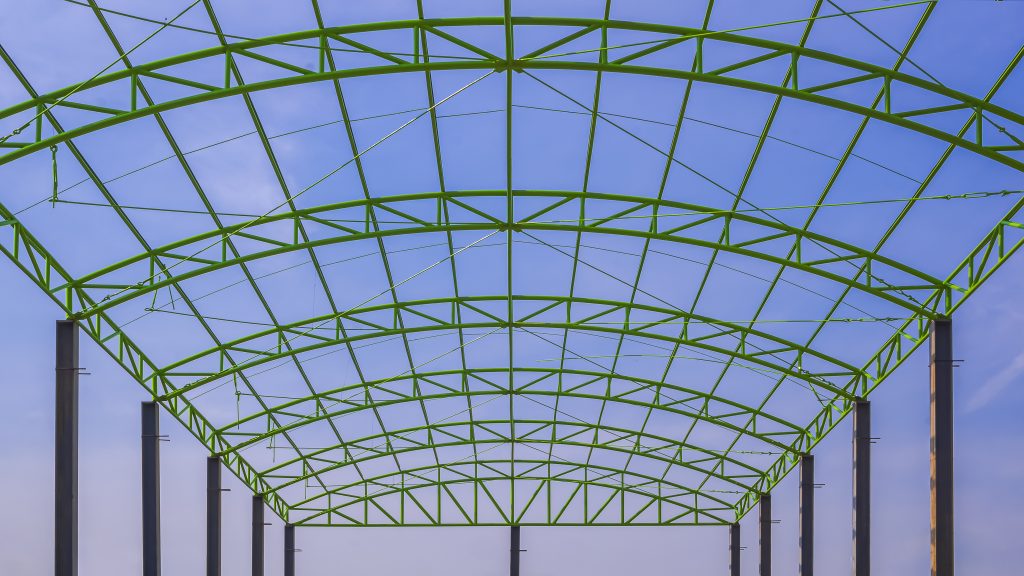

The Importance of Metallic Structures in Modern Industry

Metallic structures play a vital role across a wide range of industries thanks to their exceptional strength, durability, and adaptability. They are the backbone of manufacturing plants, logistics centers, energy facilities, and commercial buildings — providing robust and long-lasting solutions capable of withstanding demanding operational conditions.

Their versatility allows engineers and designers to create frameworks that combine structural efficiency with aesthetic precision, meeting the diverse needs of industrial, architectural, and infrastructural applications. As technology advances, metallic structures continue to evolve, offering enhanced performance, sustainability, and cost-effectiveness for modern engineering projects.

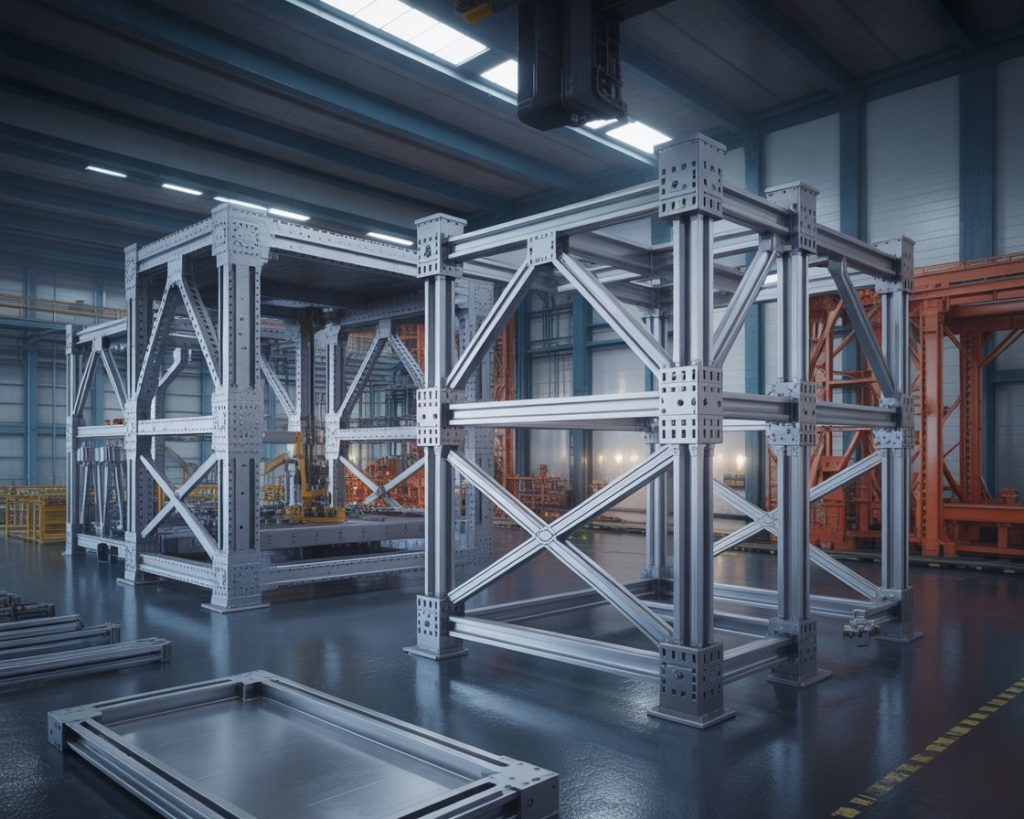

High-Quality Materials and Fabrication

At SUMIPARTS, we work with a wide range of metals — including carbon steel, stainless steel, and aluminum — depending on the specific application. Each material is selected based on mechanical strength, corrosion resistance, and weight efficiency.

Our fabrication process integrates CNC machining, laser cutting, and welding under strict quality control, ensuring dimensional accuracy and superior surface finishes. The result is a product that meets international standards and guarantees long-term performance.

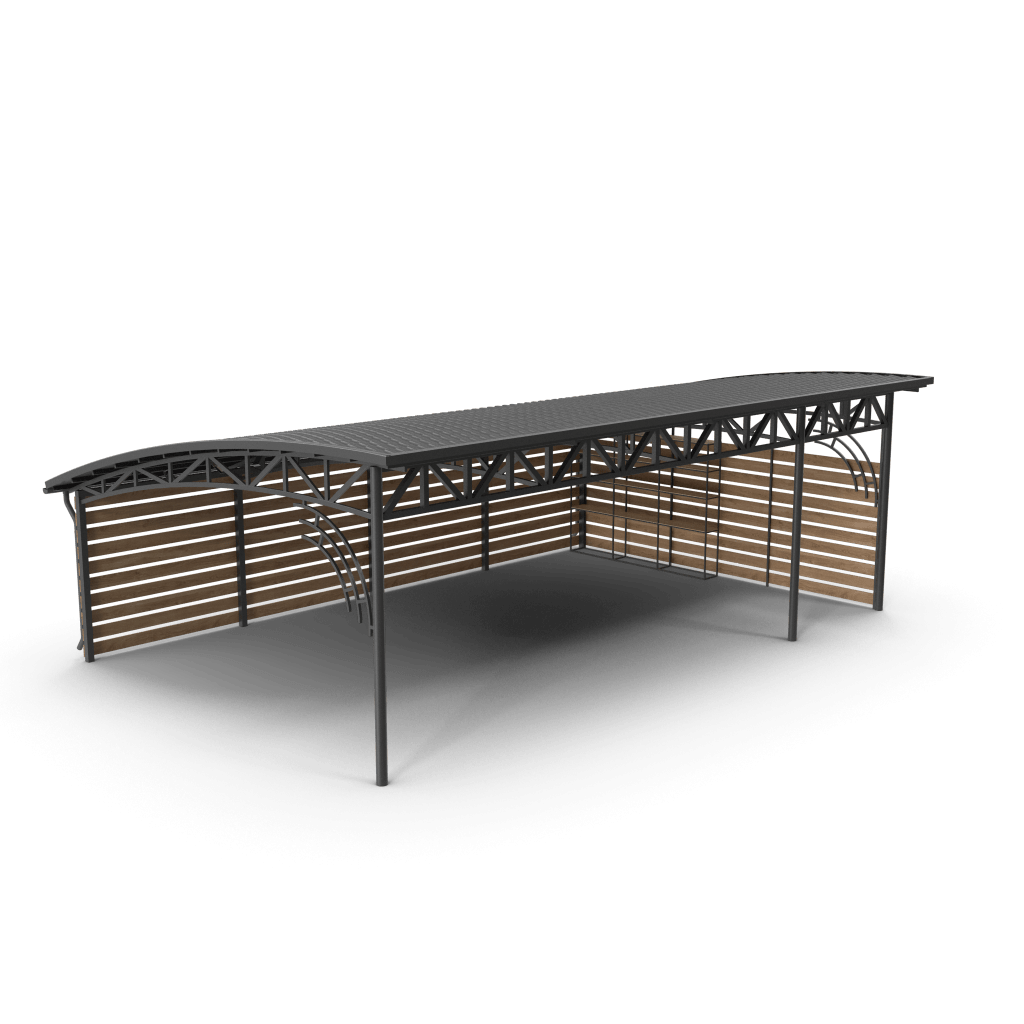

Applications of Metallic Structures

Metallic structures are essential in multiple sectors due to their adaptability and mechanical performance. Some of the most common applications include:

Industrial frames and support systems

Machinery bases and equipment housings

Architectural frameworks and structural reinforcements

Transportation and automotive assemblies

Custom metal parts for automation and robotics

Each project is developed with a focus on efficiency, safety, and durability, meeting the specific needs of industries such as construction, energy, and manufacturing.

Commitment to Quality and Innovation

At SUMIPARTS, quality is not just a requirement — it is a fundamental value that defines every stage of our production process. From the initial design and material selection to manufacturing, assembly, and final inspection, each phase is guided by a strict quality assurance system that guarantees the precision, durability, and reliability of our metallic components.

We implement rigorous dimensional verification, mechanical testing, and surface inspections to ensure that every structure complies with the most demanding international standards, including ISO, ASTM, and other globally recognized certifications. This attention to detail allows us to deliver products that perform flawlessly even under the most challenging industrial conditions.

Our commitment to innovation drives us to constantly evolve. SUMIPARTS continually invests in advanced technologies such as automated welding systems, CNC machining, metal forming, and 3D digital modeling, enabling greater precision, repeatability, and production efficiency. By integrating these technologies, we reduce manufacturing times, minimize human error, and optimize material usage — ensuring sustainable, high-performance results.

Through continuous improvement, research, and the adoption of Industry 4.0 principles, SUMIPARTS reinforces its position as a trusted partner in precision metal fabrication, delivering solutions that exceed expectations in both quality and innovation.