Plastic injection molding has long been a cornerstone of global manufacturing, but the rise of high-precision plastic injection molding is pushing the industry into a new era. As companies demand tighter tolerances, lighter components, and higher durability, precision-driven processes are becoming essential. In 2026, the need for consistent quality and advanced functionality is stronger than ever, especially in sectors like automotive, electronics, medical devices, and consumer products.

Manufacturers are recognizing that small defects—whether dimensional deviations, surface imperfections, or material inconsistencies—can significantly impact performance. High-precision plastic injection molding solves these issues by integrating cutting-edge machinery, advanced materials, and optimized processing methods. As a result, today’s molded components achieve levels of accuracy that were previously out of reach.

This evolution marks an important turning point: products are no longer just molded—they are engineered through enhanced control and smart technology, ensuring predictable and repeatable results at scale.

How High-Precision Plastic Injection Molding Works

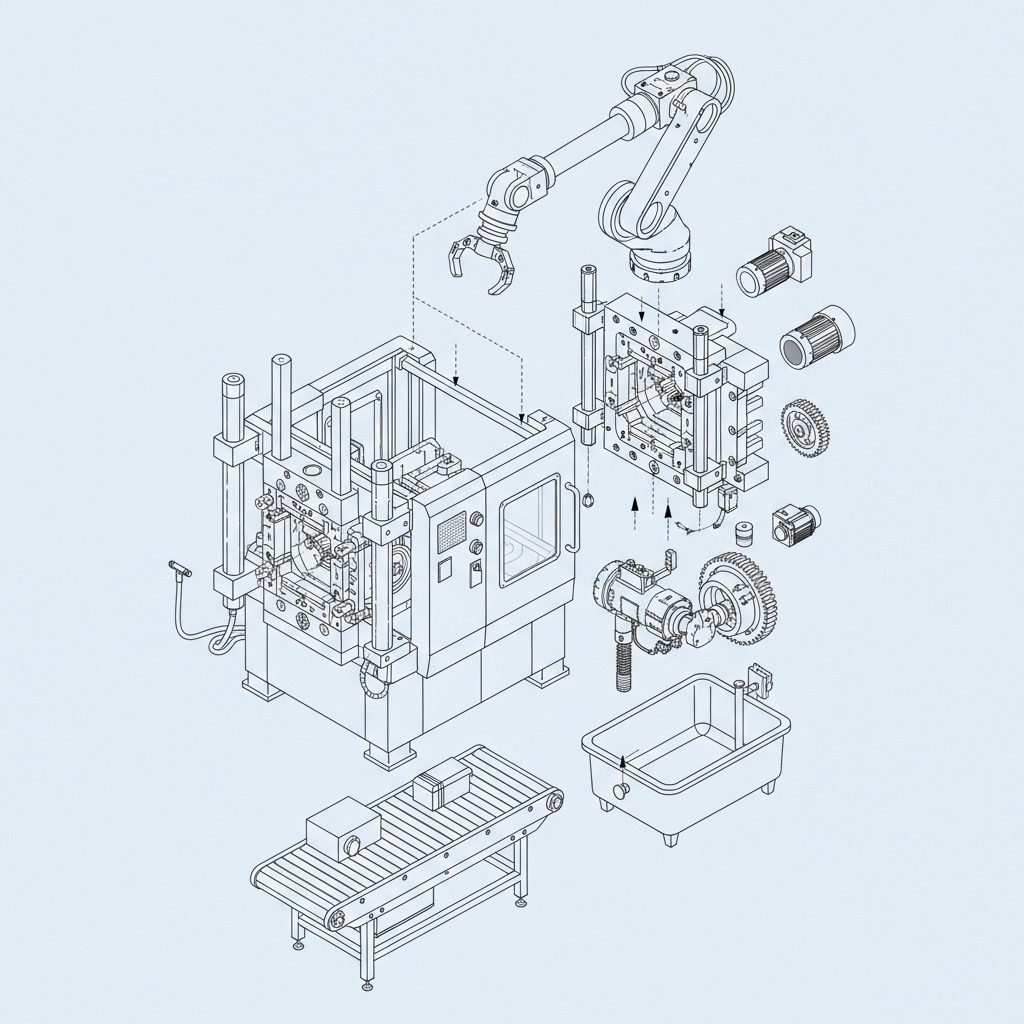

High-precision molding relies on strict control of every stage of the injection cycle. The process begins with highly engineered molds made from tool steels capable of withstanding thermal and mechanical stress. These molds include optimized gating systems, cooling channels, and venting paths that help maintain dimensional accuracy.

The machinery used in precision molding stands apart from conventional injection equipment. Modern machines incorporate:

-

Servo-electric drives for exact control of pressure and injection speed

-

Closed-loop monitoring systems that adjust parameters in real-time

-

High-resolution sensors to track temperature fluctuations

-

Micro-dosing capabilities for extremely small parts or specialized geometries

All these elements allow manufacturers to produce plastic components within tolerances as small as ±0.01 mm, depending on the application.

Material selection is another critical part of the process. Engineers choose resins based on shrinkage rate, flow characteristics, and long-term stability. Engineering plastics—such as PC, PA, PBT, TPU, and high-performance polymers—are commonly used because they maintain predictable behavior under repeated thermal cycles.

Key Advantages of High-Precision Molding for Modern Industries

High-precision plastic injection molding delivers several transformative benefits that make it essential for today’s manufacturing environment.

1. Superior Dimensional Accuracy

In industries such as electronics, where components must fit together with near-perfect alignment, precision molding ensures consistent part geometry across millions of units.

2. Enhanced Structural Performance

Precise control over resin flow and cavity pressure results in strong, reliable components with fewer internal stresses and minimal warping.

3. Reduced Defects and Rework

Better stability means fewer surface defects, weld lines, sink marks, or short shots—significantly lowering scrap rates and improving production efficiency.

4. Scalability for Mass Production

Once a precision mold and process are fine-tuned, manufacturers can run long production cycles with predictable and repeatable results.

5. Compatibility with Advanced Materials

High-performance plastics—reinforced, medical-grade, or heat-resistant—benefit greatly from the stability of precision molding.

These advantages make the method indispensable for emerging technologies that require flawless performance, such as EV components, IoT sensors, micro-connectors, and wearable devices.

Applications Where Precision Molding Makes the Biggest Impact

The use of high-precision plastic injection molding is rapidly expanding across industries, each with its own performance demands.

From diagnostic equipment to implant components, medical applications require extremely tight tolerances and consistent mechanical properties. Precision molding makes this possible while ensuring regulatory compliance.

Automotive Engineering

Modern vehicles rely on lightweight, complex plastic parts for safety systems, electronics enclosures, and engine components. Accuracy ensures reliable functionality under thermal and mechanical stress.

Electronics and Micro-Components

Micro-molded parts for connectors, switches, lenses, and chip housings depend entirely on precision to function correctly in compact devices.

Industrial & Consumer Products

Any product requiring durability, aesthetic quality, or precise assembly alignment benefits from improved molding precision.

Why Precision Injection Molding Will Keep Growing Beyond 2026

The manufacturing landscape continues evolving toward miniaturization, customization, and higher performance, which increases the demand for plastic injection molding as a core production method. As industries adopt more automation and digitized production lines, plastic injection molding aligns perfectly with this transition by delivering reliable precision, repeatability, and scalable efficiency.

Future trends that will further strengthen the role of plastic injection molding include:

-

Integration of AI-driven process optimization to stabilize molding cycles

-

Smart molds equipped with embedded sensors that monitor pressure, temperature, and flow in real time

-

Increased use of sustainable and bio-based plastics compatible with plastic injection molding

-

Hybrid molding methods that combine multiple materials or insert molding techniques

-

Real-time quality analytics that detect defects immediately and enhance consistency in plastic injection molding applications

These innovations will continue elevating precision standards and expanding what can be achieved through plastic injection molding, ultimately reshaping product design, manufacturing strategies, and component performance across global industries.

Conclusion

High-precision plastic injection molding is not merely an upgrade to traditional molding—it is a foundational change in how products are engineered. With tighter tolerances, smarter machines, and higher material performance, industries can produce components that meet demanding requirements for reliability, safety, and innovation. As 2026 unfolds, precision molding will continue to be a driving force behind advanced manufacturing.

Got questions? Go to our Contact Us page and send us a message — we’re here to help.