EPDM Rubber: Vulcanizing and Extrusion Capabilities

EPDM Rubber (Ethylene Propylene Diene Monomer) is a high-performance synthetic elastomer known for its exceptional durability, abrasion resistance, and mechanical strength. It offers excellent electrical insulation, stability against weathering, UV radiation, and ozone, as well as resistance to acids, alkalis, and extreme temperature fluctuations. These properties make EPDM an ideal material for industrial, automotive, and construction applications, where reliability and long-term performance are critical

In Sumiparts SAS we highlight our ability to develop VULCANIZING processes, for the manufacture of all types of parts. We accompany you throughout the process, starting with the design and construction of the mold, VULCANIZING process and large production volume, guaranteeing the highest quality standards.

We also highlight our ability to develop EXTRUSION processes according to the geometry desired by our customers, we highlight the large volume of production maintaining the highest quality standards

Industrial Applications and Advantages of EPDM Rubber

EPDM Rubber is a highly versatile synthetic elastomer widely used across the automotive, industrial, and construction sectors. Its exceptional durability, elasticity, and weather resistance make it the preferred choice for components that require long-lasting performance under extreme environmental conditions, including UV exposure, ozone, temperature fluctuations, and mechanical stress.

In the automotive industry, EPDM rubber is extensively applied to the production of hydraulic seals, gaskets, insulation components, and vibration dampers. These parts ensure optimal performance, leak prevention, and long-term reliability in vehicles, contributing to overall safety and operational efficiency. EPDM’s resistance to heat, ozone, and chemicals makes it especially suitable for engine components, door seals, and window weatherstrips, where precision and material stability are critical.

Within the construction and civil engineering sector, EPDM rubber plays a key role in waterproofing systems, roofing membranes, floor tiles, sports surfaces, and expansion joints. Its high UV and weather resistance allows buildings and infrastructures to maintain structural integrity over time, even when exposed to harsh environmental conditions. EPDM is also used in flooring and protective coatings where flexibility, impact absorption, and durability are required.

In the industrial manufacturing sector, EPDM is widely used for hoses, protective covers, vibration pads, conveyor components, and chemical-resistant seals. Its mechanical strength, abrasion resistance, and elasticity make it ideal for applications that involve continuous motion, pressure, or chemical exposure, ensuring high performance and long service life.

At Sumiparts SAS, our experienced engineering team leverages advanced vulcanization and extrusion processes to design and manufacture custom EPDM components that meet exacting specifications. From mold design and prototyping to full-scale production, we guarantee precision, high quality, and consistent performance in every part we produce. Our processes allow for large production volumes while maintaining strict quality standards, ensuring reliability and efficiency for all industrial applications.

If you are seeking reliable EPDM manufacturing solutions, Sumiparts SAS is ready to assist with innovative design, technical expertise, and top-tier service. We combine advanced technology with engineering excellence to deliver durable, high-performance EPDM rubber components tailored to the unique needs of our clients across automotive, industrial, and construction markets.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 318 728 7721 WhatsApp click here, or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.

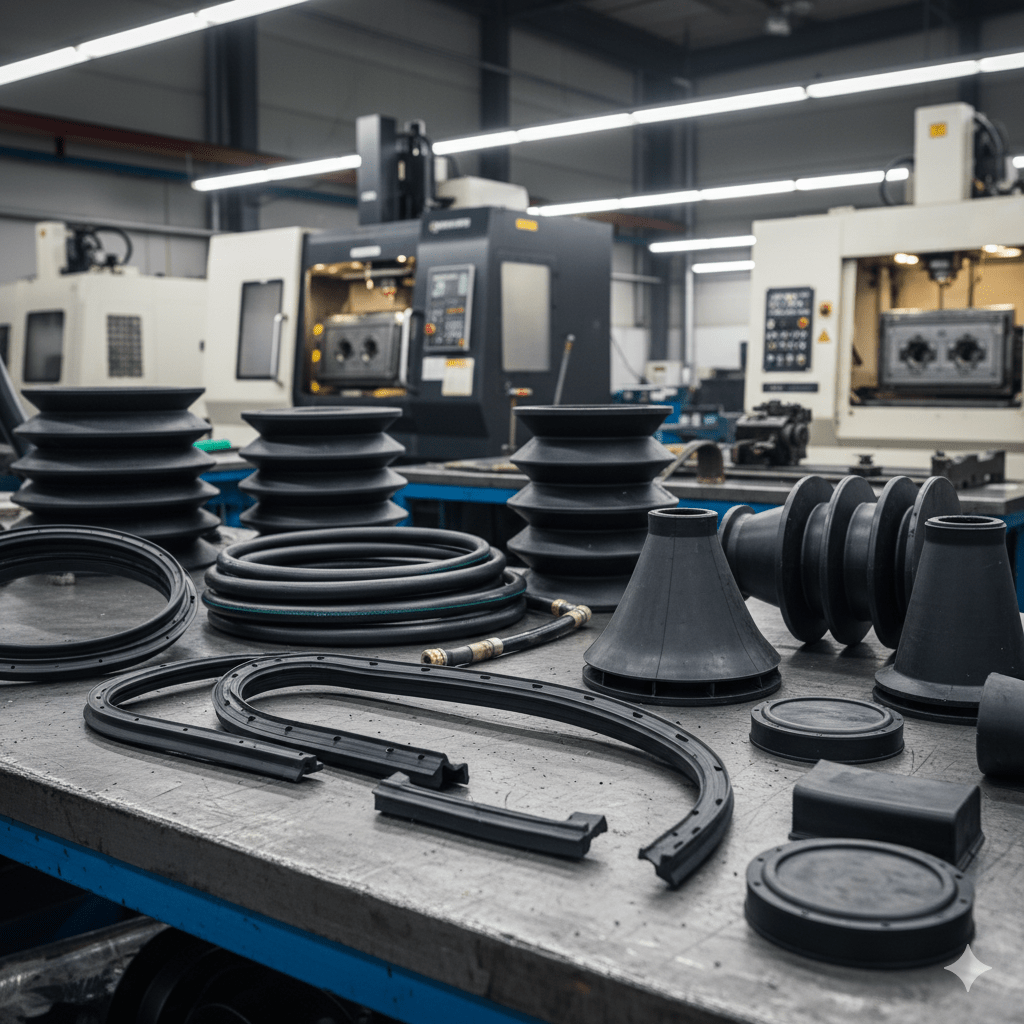

Practical Cases and Examples of EPDM Parts

EPDM rubber is an exceptionally versatile material, widely used across automotive, construction, and industrial sectors due to its outstanding flexibility, chemical resistance, and durability under extreme conditions. Its unique properties make it ideal for components that must endure repeated mechanical stress, exposure to heat, moisture, and UV radiation, and aggressive chemical environments. Here are some practical cases and examples of EPDM parts:

Automotive Seals and Gaskets: EPDM is extensively used for door seals, window gaskets, trunk seals, and sunroof seals. These components provide excellent flexibility, maintain tight tolerances, and ensure long-term performance, even under extreme temperature variations and harsh weather conditions. The elasticity and resilience of EPDM allow these parts to return to their original shape after repeated compression, ensuring vehicle integrity and passenger comfort.

Construction Expansion Joints and Profiles: In building and infrastructure projects, EPDM profiles are used in expansion joints, floor and bridge sealing, roofing membranes, and window or door frames. These components withstand UV radiation, ozone, and wide temperature fluctuations, making them ideal for outdoor applications where long-term durability and performance are critical. EPDM also provides excellent water resistance, preventing leaks and protecting structural elements.

Industrial Vibration Dampers and Shock Absorbers: EPDM rubber pads, mounts, and cushioning components are used to reduce vibrations and absorb shocks in machinery and equipment. This helps extend the life of machines, reduce maintenance costs, and improve operational safety. EPDM’s mechanical resilience allows it to maintain performance even under continuous dynamic loading.

Hydraulic and Pneumatic Seals: EPDM gaskets, o-rings, and hoses are widely applied in hydraulic and pneumatic systems. These parts maintain high chemical and temperature resistance while providing excellent sealing capabilities. EPDM ensures tight connections and prevents leaks in systems handling water, oils, or certain chemicals, making it a reliable choice for industrial operations.

Protective Covers, Insulators, and Custom Components: EPDM sheets, molded parts, and custom extrusions are used to create protective covers, insulators, and barriers for sensitive equipment. These components resist dust, moisture, and corrosion while providing electrical insulation, mechanical protection, and long-term durability in industrial environments.

Overall, these practical examples demonstrate how EPDM rubber can be customized for highly specialized industrial applications, providing components that combine flexibility, strength, and environmental resistance. From automotive seals to industrial shock absorbers and construction profiles, EPDM rubber remains a preferred material for manufacturers seeking reliable, high-performance solutions.