AISI 4140 Steel CNC Milling Process

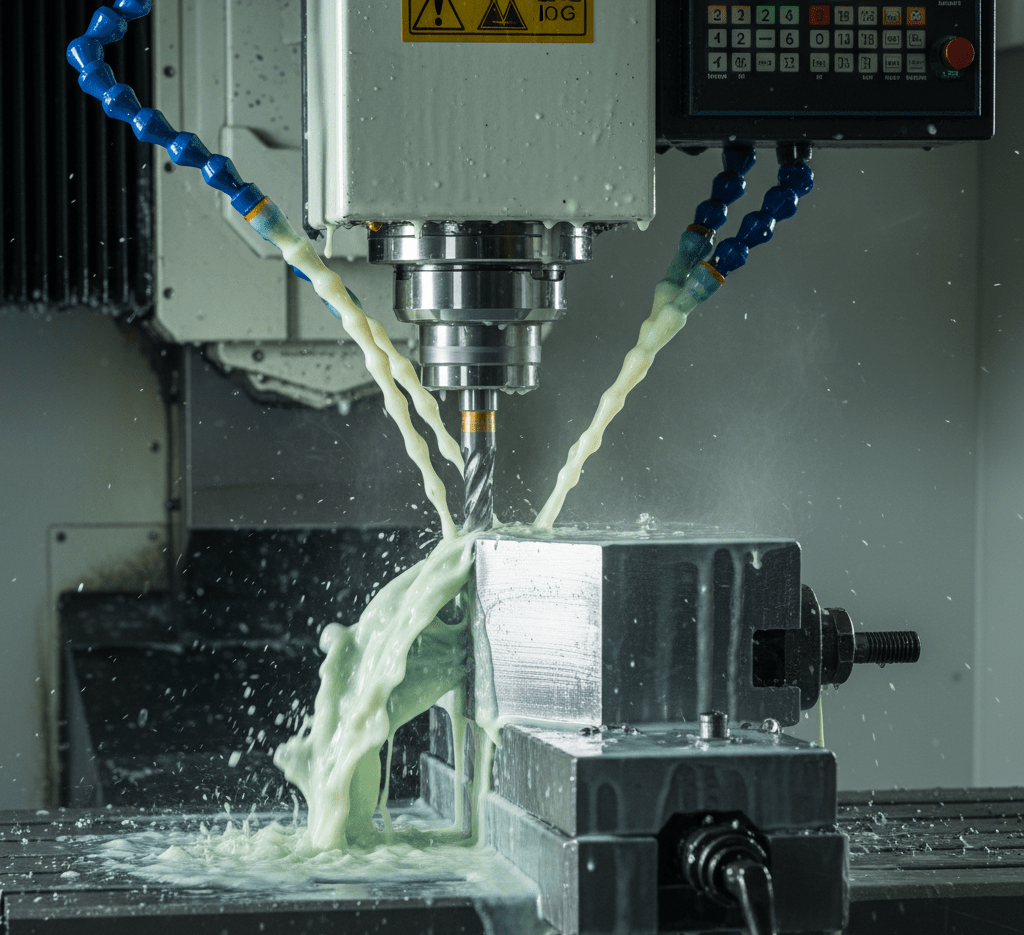

The milling of AISI 4140 steel is a precision machining process that involves cutting the alloy using a multi-edge carbide rotary tool, which executes carefully programmed feed movements to achieve the desired geometry, dimensional accuracy, and surface finish. At Sumiparts SAS, we provide CNC milling services that allow for complex, multi-directional machining, thanks to advanced machines with three axes, ensuring precision and reliability for industrial, automotive, and mechanical components.

The CNC milling process is carried out in several critical steps:

Programming: Skilled operators use CAM (Computer-Aided Manufacturing) for manual setup or CAD (Computer-Aided Design) for automated programming. This involves entering numerical and letter codes based on precise calculations, ensuring the cutting path will produce the exact design required.

Material and Tool Setup: The steel workpiece is securely clamped, and the appropriate cutting tool is selected according to the type of milling operation, the desired surface finish, and the mechanical requirements of the part. Proper setup ensures minimal vibration, reduced wear on the tools, and consistent results throughout production.

Precision Milling: The CNC machine executes the programmed path, performing high-precision cuts in multiple axes. This allows for the creation of complex geometries, angled surfaces, pockets, slots, and other features that would be impossible to achieve with conventional milling. Throughout the process, the mechanical properties of AISI 4140 steel—such as hardness, tensile strength, and toughness—are maintained.

Quality Inspection: Every milled component undergoes a thorough quality check. This includes measuring dimensional accuracy, surface finish, and geometric tolerances to ensure compliance with the specifications. Parts are inspected using precision instruments to guarantee that each component meets high engineering standards.

Advantages of CNC Milling for AISI 4140 Steel

High precision and repeatability: Ideal for components that require tight tolerances

Ability to handle complex geometries: Enables custom designs and intricate features

Material efficiency: Reduces waste while maintaining mechanical strength

Superior surface quality: Smooth finishes suitable for post-processing, assembly, or coating

Consistency for high-stress applications: Essential for automotive, industrial, and mechanical parts

By combining advanced CNC technology with experienced engineering personnel, Sumiparts SAS ensures that AISI 4140 steel components are delivered with optimal precision, durability, and performance, ready for demanding industrial applications. Our CNC milling services are particularly suited for shafts, gears, flanges, tooling components, and custom mechanical parts that require high reliability and long service life.

.

Finishes achieved with the Milling of AISI 4140 Steel

With the computer numerical control milling machine, or CNC, and with its various types of milling, all kinds of finishes are achieved in the machining process.

– Cutting milling, is the most basic because it is the first to be used to adapt the material to the needs of the job.

– Planned, to flatten the surface.

– Square, used to make a stepped surface.

– Cubic, to create cubic shaped pieces.

– Straight grooving, creates linear grooves.

– Shape grooving, to make T-shaped grooves.

– Keyway grooving, a type of asymmetric trapezoidal groove.

– Lathe-milling, to make holes and an external milling when surrounding the piece. Depending on the type of milling, a different milling cutter is used

In the specific case of AISI 4140 Steel, as it is an alloyed carbon steel, which is widely used in the manufacture of medium and small section parts, high fatigue and torsion efforts are required, which is why the use of CNC machining becomes more indispensable and must be much more judicious.

For the milling of AISI 4140 Steel, it must be taken into account that there is a wide variety on the market, with different surface finishes: cold drawn, hot rolled, peeled, pre-machined , smooth forging, rough, etc.Depending on these different categories, there is the possibility of giving them a heat treatment.

The applications of products developed under this process, range from parts for the automotive industry, parts for machinery, forged parts, parts for the oil industry, high strength fasteners, among others.

The Steel Milling process of Sumiparts SAS, allows to create custom parts and products, and with our system the productivity, quality and accuracy of the procedures carried out are considerably increased.

If you want to know more about this milling service in AISI 4140 Steel, in SUMIPARTS we will be at the greatest disposition to collaborate. We want to provide you with the best services at your fingertips.

Contact us by calling the landline +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click aquí , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you, we leave you these links that may be of your interest Aluminum rolling