Acetal (POM): High-Performance Engineering Plastic

Acetal (Polyacetal or POM) is a high-performance engineering plastic widely recognized for its exceptional strength, rigidity, dimensional stability, and wear resistance, making it a reliable substitute for metals in demanding industrial applications. Its excellent mechanical properties, combined with chemical and moisture resistance, allow for the production of precision components that perform consistently under dynamic loads and long-term use.

CNC MACHINING: At SUMIPARTS SAS, we specialize in CNC machining of Acetal (POM), guaranteeing tight tolerances, precise dimensions, and complex geometries. Our experienced engineering team works with advanced CAD/CAM software to study, design, and simulate parts before production. This ensures high-volume manufacturing, minimal material waste, and timely delivery without compromising quality. Our machining capabilities include milling, turning, drilling, and intricate shaping for components used in automotive, industrial machinery, electronics, and construction applications.

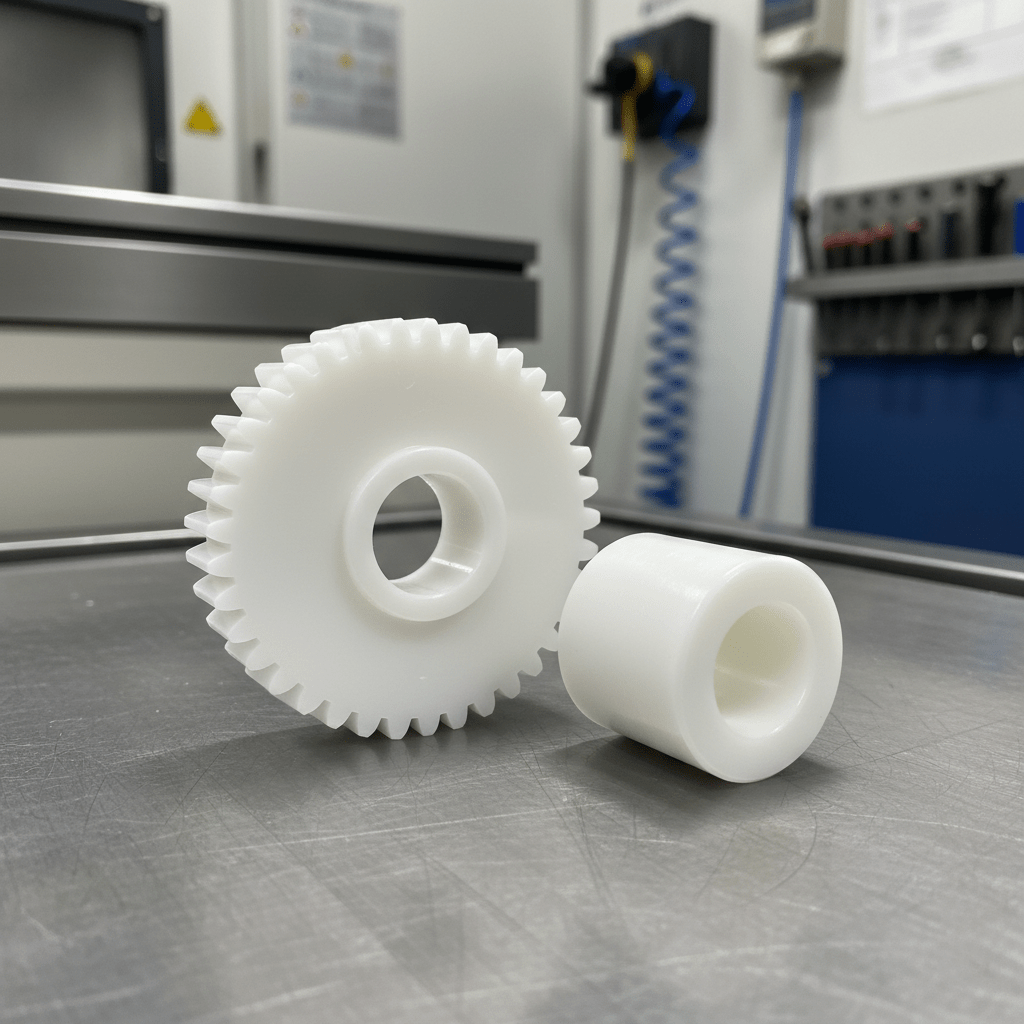

CNC Turning: For cylindrical or rotational components, CNC turning represents the most efficient and precise manufacturing method. Using state-of-the-art lathes, we can produce Acetal parts with tight dimensional tolerances, superior surface finish, and high repeatability, while keeping production costs competitive. This process is ideal for bushings, spacers, rollers, and custom cylindrical components required in high-performance industrial systems.

ACETAL CNC MILLING: Our advanced CNC milling equipment allows us to develop special fabrications, in-line production, and complex geometries with exceptional precision. Whether for prototypes, medium runs, or high-volume production, our milling capabilities ensure consistent quality, reduced lead times, and optimal material performance. Components such as gears, housings, structural supports, and precision mechanical parts are efficiently produced to meet strict industrial standards.

At SUMIPARTS SAS, every stage of Acetal CNC machining is carefully monitored, combining engineering expertise, advanced machinery, and rigorous quality control. The result is durable, precise, and high-performance POM components that can replace metal parts in a wide range of industrial applications, offering cost-effective solutions without sacrificing reliability or functionality.

Sumiparts SAS delivers precise, high-quality Acetal (POM) components on time, every time.

Main Applications of Acetal (POM) in Industry

Acetal (POM) is a highly versatile engineering plastic, widely recognized for its combination of strength, rigidity, wear resistance, and dimensional stability. These properties make it an ideal material for industrial components that must endure continuous mechanical stress, maintain precision, and perform reliably under demanding conditions. Its ability to resist moisture, chemicals, and heat further expands its suitability for diverse industrial sectors.

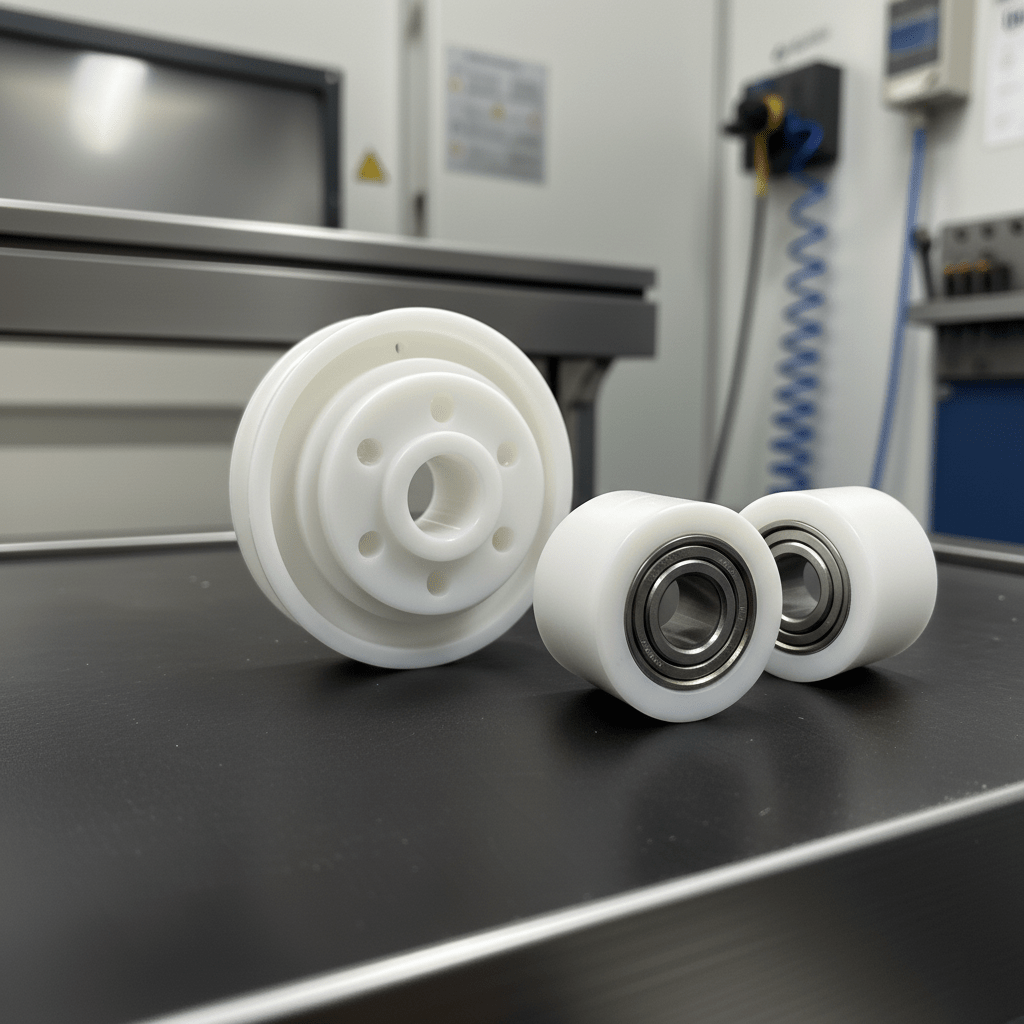

In the automotive industry, Acetal is extensively used for the production of gears, bushings, bearings, and small structural components. These parts benefit from the material’s low friction coefficient and excellent wear resistance, allowing them to operate smoothly over long periods without compromising vehicle performance or safety. Acetal also contributes to lightweighting vehicles, helping reduce fuel consumption while maintaining structural integrity.

In industrial machinery, the applications are numerous. Components such as conveyor rollers, guide rails, mechanical washers, pulleys, and precision bushings leverage Acetal’s mechanical properties for reliable operation. Its dimensional stability ensures that moving parts retain alignment, reducing downtime and maintenance costs. Moreover, the material’s low friction reduces energy loss and wear, improving overall efficiency in automated systems.

The food processing sector also benefits from Acetal’s unique characteristics. Cutting tables, conveyor components, and other parts made from Acetal maintain hygiene standards, resist moisture and repeated cleaning, and sustain long-term mechanical performance. The material’s non-porous nature and stability at varying temperatures make it ideal for environments that require consistent reliability.

In construction and infrastructure applications, Acetal is used for expansion joints, structural supports, and low-friction sliding guides. Its durability under dynamic loads and exposure to environmental factors ensures long-lasting performance in demanding settings, from machinery assemblies to heavy-duty structural components.

At SUMIPARTS SAS, our team of experienced engineers and production specialists supports clients at every stage of the process. From initial design and prototyping to CNC machining, molding, and extrusion, we provide tailored solutions that meet each customer’s specific requirements. Our approach emphasizes quality assurance, precision, and efficiency, ensuring that each component performs reliably and contributes to operational excellence.

By combining advanced machinery, rigorous quality control, and in-depth engineering expertise, SUMIPARTS SAS delivers Acetal (POM) parts that meet the highest industrial standards. Whether for automotive, industrial, construction, or specialized machinery applications, our components offer durability, consistent performance, and a cost-effective alternative to metal parts, helping clients optimize production and extend equipment life.

At SUMIPARTS SAS, our engineering and production teams ensure that each component is carefully designed and manufactured. From prototype development to final machining and finishing, we provide customized solutions that meet strict industrial standards. This approach guarantees that every part delivers consistent performance, durability, and efficiency, helping clients optimize their operations and extend the life of their equipment.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 318 728 7721 WhatsApp click here , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.