Turning Parts with Revolver Lathe: Specialized Service by Sumiparts SAS

Turning Parts with revolver lathe represents one of the most specialized services within Sumiparts SAS’s portfolio for creating small components and completely customized products according to each client’s specific needs. This turning parts process with revolver lathe enables the manufacturing of revolution geometry components through a multiple-tool system that significantly optimizes production times.

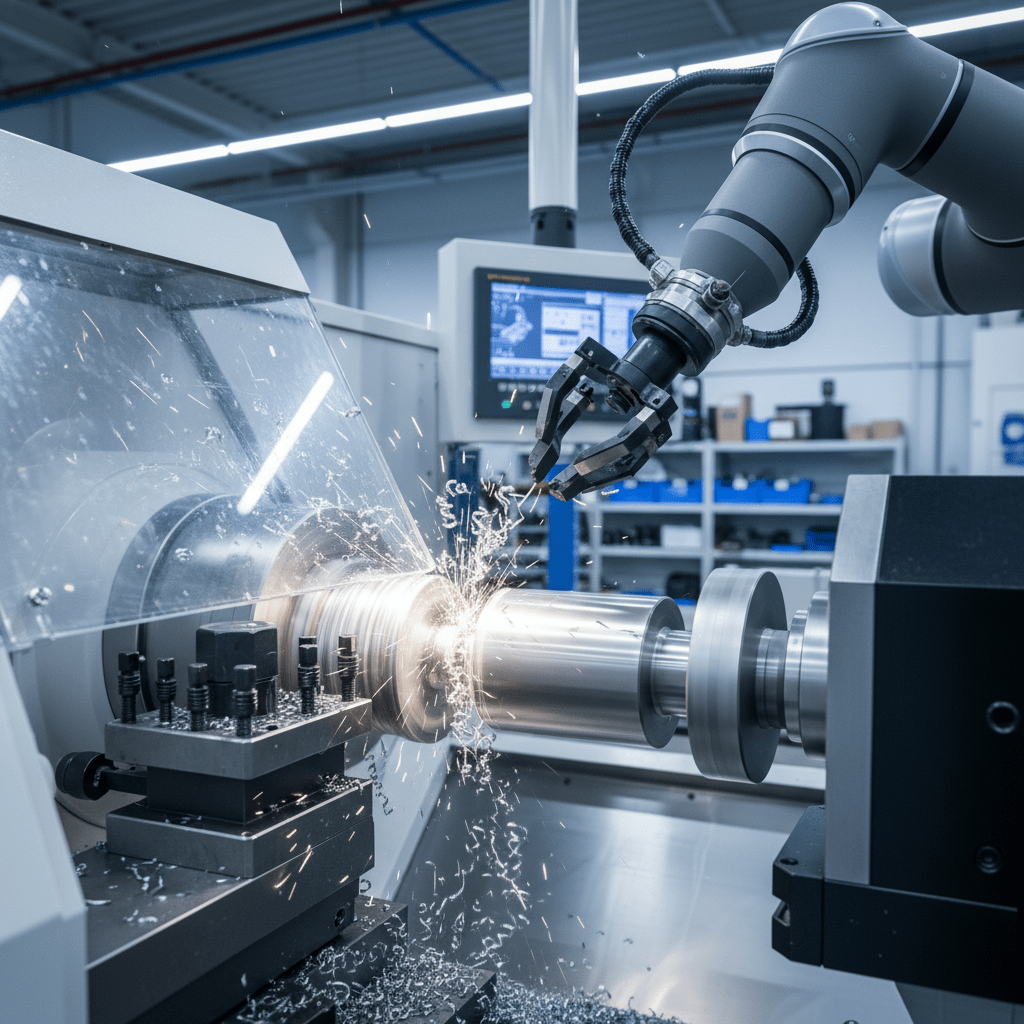

At Sumiparts SAS, complementing our advanced CNC machining technology, we operate revolver lathe machinery managed by highly qualified operators whose expertise guarantees maximum precision in every turning parts project. The implementation of revolver lathe for turning parts constitutes an ideal solution for components requiring multiple machining operations in a single setup, while maintaining strict tolerances and excellent surface finishes.

The Turning Parts Process with Revolver Lathe at Sumiparts

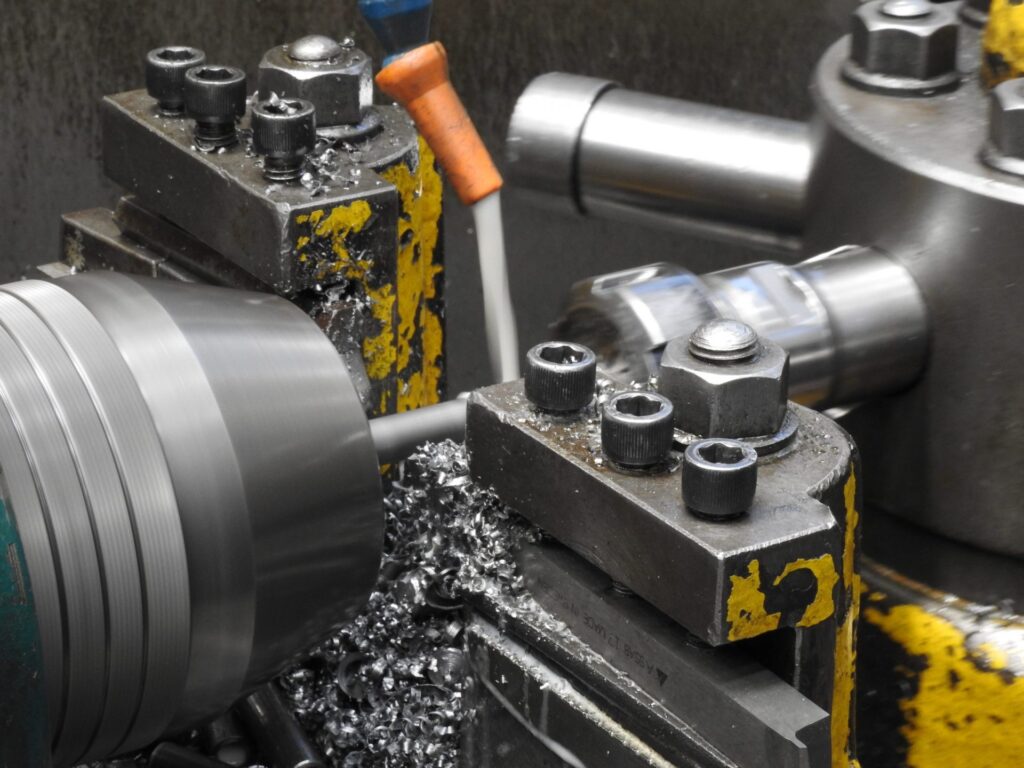

The machining process for Turning Parts using a revolver lathe operates by rotating the workpiece held in the headstock or fixed between center points, while multiple cutting tools perform controlled feed movements against the material surface, removing chips precisely and consistently. This advanced Turning Parts manufacturing system with a revolver lathe allows executing complex operations sequentially without the need to change the workpiece between machines, ensuring perfect concentricity and dimensional accuracy across all turned components.

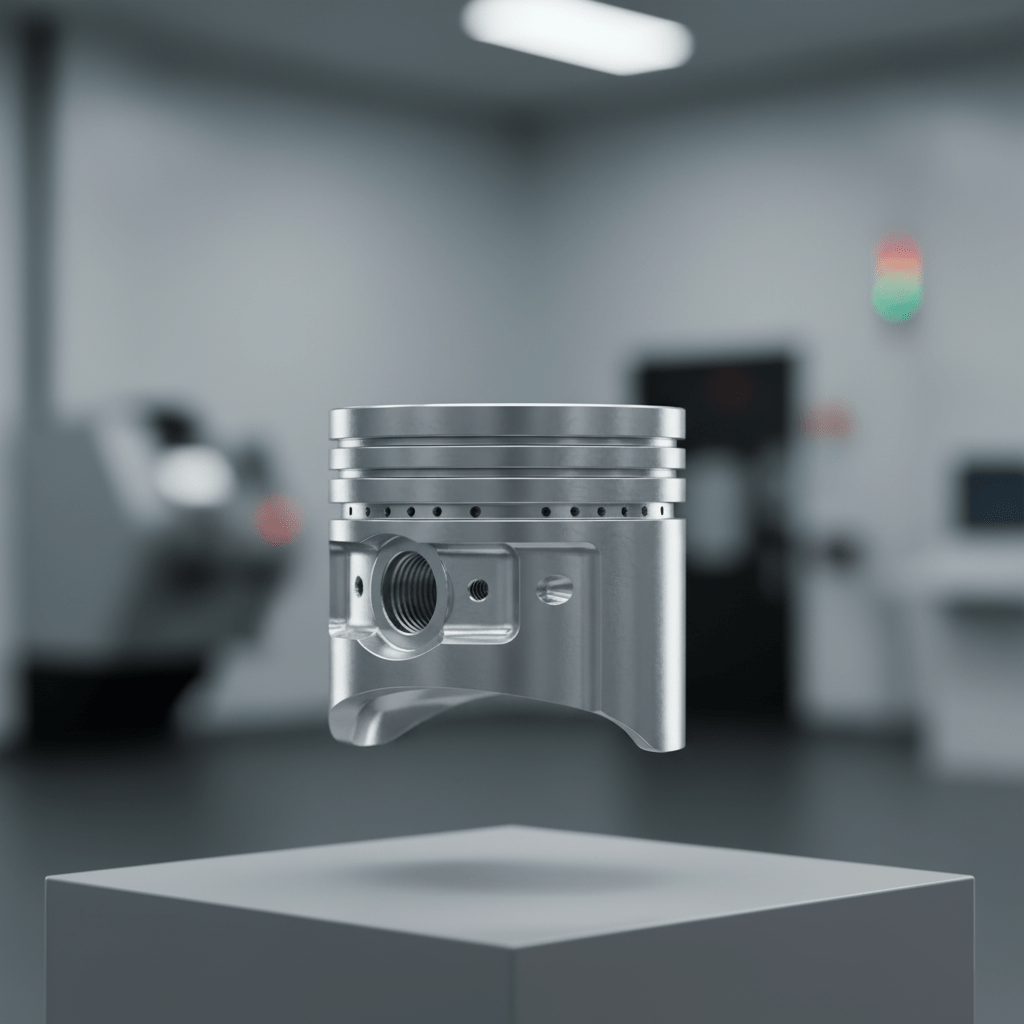

One of the main advantages of Turning Parts machining with a revolver lathe lies in its ability to work simultaneously with multiple tools, dramatically reducing total machining time and increasing production efficiency. This Turning Parts process is particularly suitable for components that, starting from bars, achieve final shapes such as bushings, shafts, or precision cylindrical geometries required in automotive, industrial, and mechanical applications.

During the Turning Parts manufacturing process, once the bar is securely positioned using high-precision collets or jaw chucks, internal operations such as drilling, threading, boring, and reaming are performed simultaneously, while external operations like facing, threading, grooving, and cutting take place on the outer surface. This synchronized machining approach guarantees smooth finishes, tight tolerances, and improved productivity across every production batch.

At Sumiparts SAS, we specialize in the production of CNC Turning Parts, combining advanced technology, automated controls, and expert craftsmanship to achieve exceptional quality standards. Our turning centers allow for continuous production of high-precision components with excellent repeatability, meeting the specific requirements of each client and industry.

Applications and Benefits of Parts Turning with Revolver Lathe

The service with revolver lathe offered by Sumiparts SAS is specifically engineered for the manufacturing of precision components that require multiple machining operations in a single setup. This process ensures perfect coaxiality and alignment between every machined feature, resulting in high-performance and dimensionally stable parts. Our turning parts production system allows the creation of stepped shafts, hydraulic and pneumatic components, precision connectors, and customized mechanical parts used across a wide variety of industrial applications.

At Sumiparts SAS, our revolver lathe technology enables the execution of several cutting operations simultaneously, minimizing handling and repositioning of the workpiece. This approach not only guarantees consistency and repeatability in each turning part but also enhances the overall speed and accuracy of production. Thanks to our state-of-the-art CNC lathes, we can produce with tight tolerances, fine surface finishes, and optimized material utilization.

Competitive Advantages of Parts Turning with Revolver Lathe at Sumiparts

The revolver lathe machining service at Sumiparts SAS is specifically designed to manufacture precision components that require multiple operations in a single setup. This process guarantees perfect coaxiality and alignment between all machined features, ensuring high performance, dimensional stability, and superior quality in every finished piece. Our production capabilities make it possible to create stepped shafts, hydraulic and pneumatic parts, precision connectors, and custom mechanical components for a wide range of industrial applications.

At Sumiparts SAS, advanced revolver lathe technology allows several cutting operations to be performed simultaneously, minimizing manual intervention and eliminating unnecessary part repositioning. This efficient workflow ensures consistent results and repeatability, while also improving the overall speed and precision of manufacturing. Equipped with state-of-the-art CNC lathes, we deliver components with tight tolerances, smooth surface finishes, and excellent material efficiency — offering our clients reliable solutions for both small and large-scale production.