Plastic Manufacturing Process

Plastic manufacturing plays a fundamental role in the development of high-performance components for a wide range of industries, including automotive, industrial machinery, construction, medical, and food processing. Due to their versatility and adaptability, plastics can be engineered to meet virtually any technical requirement, offering lightweight, durable, and cost-effective solutions for both mass production and custom applications.

At Sumiparts SAS, we specialize in precision plastic manufacturing supported by advanced machinery and strict quality control systems. Every project we develop combines innovation, material science, and engineering expertise to ensure optimal results.

We work with a wide selection of engineering polymers, each chosen for its mechanical strength, chemical resistance, and thermal stability. Materials such as Nylon, Polypropylene, Polycarbonate, PVC, and Acetal allow us to produce plastic components with excellent performance in demanding environments. Whether it’s high-impact automotive parts, industrial housings, or custom-designed plastic molds, our team ensures accuracy and consistency at every stage of production.

This commitment to quality and reliability enables Sumiparts SAS to deliver plastic manufacturing solutions that meet the highest international performance and safety standards, ensuring long-lasting and efficient results for our clients.

The plastic manufacturing process generally follows three main stages:

Obtaining Raw Materials – The process begins with the selection of resins derived from petrochemical or recycled sources. These raw materials determine the final strength, flexibility, and resistance of the plastic.

Polymer Synthesis – In this stage, monomers are chemically bonded to create polymers with specific characteristics, such as durability, elasticity, or temperature resistance.

Molding or Forming – The material is then shaped through injection molding, extrusion, or thermoforming, depending on the type of product and required precision.

Each of these stages is carried out under strict quality control, ensuring consistent results and long-lasting performance.

Through our plastic manufacturing capabilities, we guarantee products that are not only efficient and durable, but also adaptable to the evolving needs of modern industries.

Types of Plastic Molding Processes

At Sumiparts SAS, we provide a wide range of plastic molding processes designed to meet the diverse needs of modern industries. Each technique offers specific advantages in terms of precision, production volume, and material performance, allowing us to deliver efficient solutions from prototype to mass production.

Compression Molding

This process involves heating and compressing plastic powder between mold parts under high pressure. It is ideal for small or medium-sized components and is commonly used in applications similar to vulcanized rubber manufacturing, offering excellent strength and dimensional stability.

3D Printing (Additive Manufacturing)

3D printing builds plastic components layer by layer from CAD models, enabling the creation of complex geometries and prototypes. This process allows for rapid design validation before scaling up to full production, reducing development time and cost.

CNC Machining of Plastics

Through precision CNC milling and turning, this subtractive process allows us to cut, drill, and grind plastic materials with exceptional accuracy. It’s ideal for creating detailed parts with tight tolerances and excellent surface finishes, especially for engineering-grade plastics.

In this process, molten plastic is pushed through a shaped die, forming continuous profiles with specific cross-sections such as T, L, I, U, square, and circular shapes. It is a cost-effective method for producing long parts with consistent geometry.

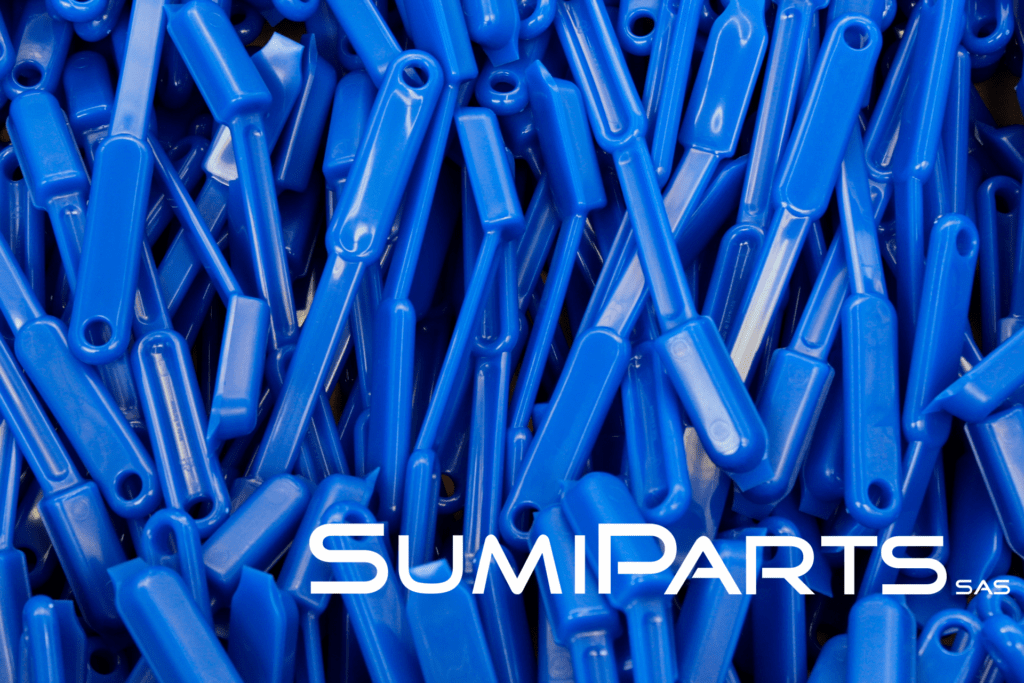

Injection molding is one of the most efficient techniques for high-volume plastic manufacturing. Molten thermoplastic is injected into precision molds to create consistent, durable components. At Sumiparts SAS, we design and manufacture complex injection molds and operate advanced injection machines that guarantee accuracy, repeatability, and material efficiency.

These plastic molding processes ensure high-quality, precise, and reliable production, supporting our clients from custom prototypes to large-scale industrial manufacturing.

At Sumiparts SAS, we guarantee excellent surface finishes, high-quality raw materials, and the ability to handle large-scale plastic manufacturing with precision and consistency. Our plastic molding and machining processes are developed under strict quality standards, ensuring durability, dimensional accuracy, and aesthetic excellence in every component.

All our integrated manufacturing processes — from product design and mold development to forming, finishing, and inspection — allow us to deliver superior results and adapt to any production requirement. This unified workflow provides our clients with greater flexibility, faster response times, and complete freedom to transform ideas into high-performance plastic products.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp clic here , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.