Manufacturing an injection mold is one of the most important and strategic investments in the plastic production industry. While the concept of Injection Mold Cost seems simple, its calculation relies on a wide range of engineering, design, and production variables. Because each mold is custom-built, no two projects share the same cost structure. Understanding these variables enables manufacturers to optimize budgets, reduce risks, and select the right tooling approach for their production goals.

Rather than focusing on numbers, this guide explains the critical factors that define Injection Mold Cost, helping engineers and decision-makers plan effectively for long-term manufacturing success.

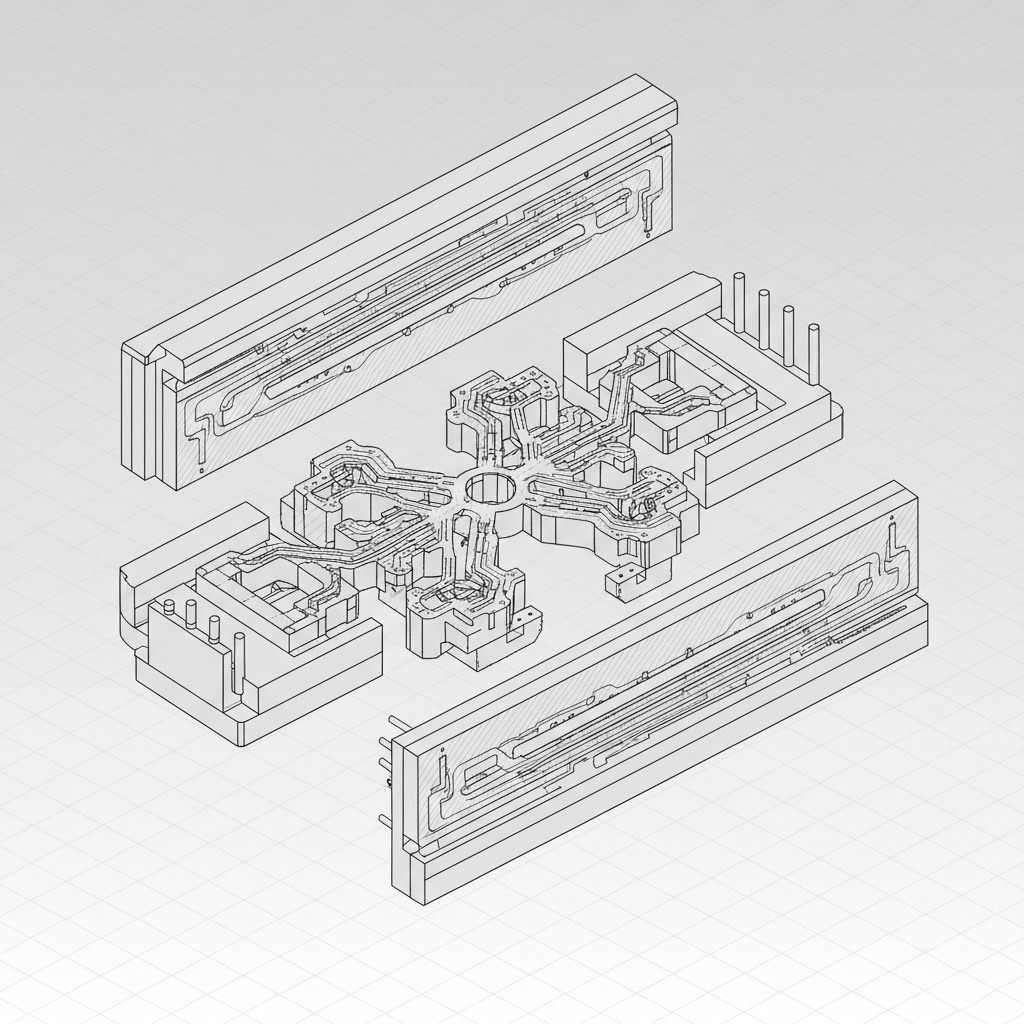

Part Geometry and Design Complexity

The complexity of the plastic part is the primary element influencing Injection Mold Cost. When a design includes thin walls, internal channels, threads, undercuts, or tight tolerances, the tooling requirements become significantly more advanced.

Complex parts may require:

Lifters, slides, or collapsible cores

Fine surface textures and precision engraving

High-tolerance machining

Multi-stage ejection systems

Each of these engineering additions increases the mold-building effort. A simple two-plate mold requires minimal machining, whereas a complex multi-action mold demands extensive labor and specialized equipment. Therefore, part design is always the first checkpoint when estimating Injection Mold Cost.

.

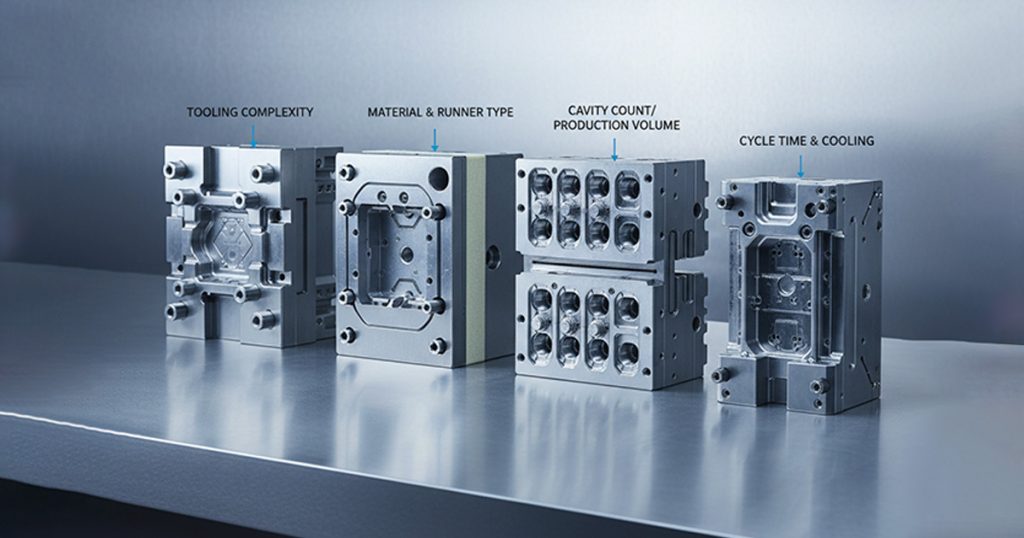

Number of Cavities

The number of cavities directly impacts mold engineering, machining time, and overall design. A mold can range from a single cavity to dozens of cavities depending on production volume.

Single-cavity molds are suitable for low-volume or highly customized parts.

Multi-cavity molds exponentially increase production speed but require advanced balancing systems, precision cooling layouts, and more robust steel choices.

More cavities mean more machining, more simulation, and more precision—not necessarily cheaper or faster to build. The decision must align with production strategy and long-term efficiency goals.

Mold Material Selection

The mold material significantly affects durability, performance, and overall Injection Mold Cost. Tool steels, aluminum alloys, and hardened steels each offer different benefits.

Aluminum is ideal for prototypes and short runs due to easier machining.

Pre-hardened steel (P20) supports medium production volumes.

Hardened steels (H13, S7, etc.) withstand millions of cycles and harsh resins.

Choosing the correct material ensures the mold lasts as long as the production plan requires. Overbuilding a mold increases investment, while underbuilding leads to premature wear and costly repairs. The right balance is crucial.

Cooling System Design

Cooling represents up to 70% of the total injection molding cycle. This makes cooling system design a major contributor to Injection Mold Cost.

Advanced cooling strategies—such as baffles, bubblers, conformal cooling, and optimized channel layouts—require more engineering and specialized machining processes. However, they reduce cycle time dramatically, improving long-term productivity.

A mold with poor cooling may be cheaper to build, but more expensive to operate. A well-engineered cooling system optimizes:

Production speed

Dimensional stability

Part repeatability

Energy efficiency

This is why cooling strategy is one of the most valuable investments in tooling.

Surface Finish and Texture Requirements

Surface finish has a significant impact on mold-building hours. A mirror-polished cavity or a specialized texture (such as SPI A1, EDM patterns, or graining) requires:

Additional hand polishing

Special texturing processes

Accurate machining to maintain fine details

The higher the cosmetic requirement, the more time and effort are needed to prepare the mold surfaces. This directly influences—and increases—the final Injection Mold Cost.

Gating and Ejection Complexity

Proper gating design is essential for resin flow, part quality, and cycle time. Likewise, the ejection system ensures the part is released smoothly without marks or deformation.

More complex parts require:

Multiple gates

Hot runner systems

Custom ejector pins or sleeves

Extended stroke mechanisms

Air ejection or hydraulic assists

These systems add engineering depth, machining steps, and quality control measures.

Mold Longevity and Expected Production Volume

The expected production lifespan of the mold determines how robust it needs to be. A mold designed for 10,000 cycles will differ greatly from one designed for 1 million cycles.

High-volume molds require:

Harder steels

Reinforced cores

Stronger components

More advanced cooling designs

This level of durability increases the initial Injection Mold Cost, but ensures minimal downtime and consistent part quality over time.

Engineering, Simulation, and Validation

Professional mold-making companies include several critical services in the tooling process:

DFM analysis

Mold flow simulation

Mechanical feasibility reviews

Material shrinkage compensation

Trial runs and sampling

These steps ensure that the mold performs correctly before production begins. Although they increase tooling cost, they drastically reduce the risk of defects, redesigns, or part failures.

Why Understanding These Factors Matters

Ultimately, Injection Mold Cost is not defined by a single variable, but by the combined engineering efforts needed to produce reliable, high-quality molds. Companies that understand these factors make smarter investments, improve production efficiency, and reduce long-term operational costs.

A well-designed mold is not an expense—it’s a strategic asset.

Got questions? Go to our Contact Us page and send us a message — we’re here to help.