Tube Laser Cutting: Precision and Efficiency in Metal Processing

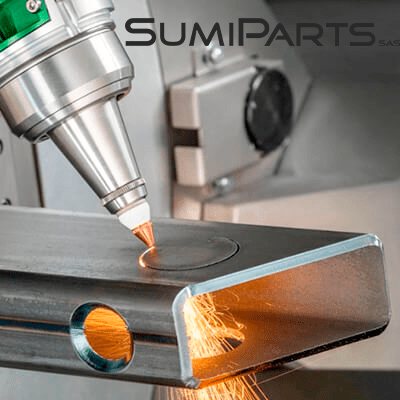

At SUMIPARTS, we specialize in tube laser cutting services designed to meet the high demands of modern industries. This cutting-edge process combines speed, precision, and versatility, enabling the production of complex metal components with exceptional quality and consistency.

Our advanced laser systems allow us to cut metal tubes, profiles, and structural parts of different diameters and thicknesses, maintaining tight tolerances and superior surface finishes. This makes laser cutting one of the most efficient solutions for fabricating metal parts that require clean, precise, and repeatable results.

Unlike conventional cutting methods, tube laser cutting minimizes waste, reduces production time, and eliminates the need for additional finishing processes — translating into cost savings and higher productivity for every project.

Advantages of Tube Laser Cutting

Laser technology provides numerous advantages compared to mechanical or plasma cutting. At SUMIPARTS, we integrate CNC-controlled systems to achieve maximum efficiency and quality.

Key benefits include:

Unmatched precision: CNC-guided tube laser cutting systems ensure perfect dimensional control in every operation. This level of accuracy allows for consistent quality, even in high-volume production.

Complex geometries: The flexibility of tube laser cutting enables the creation of intricate holes, slots, and patterns on round, square, and rectangular tubes. These complex contours are achieved with minimal deformation and without compromising the material’s structural integrity.

High-speed production: Automated feeding, alignment, and cutting systems reduce setup times and optimize throughput, making tube laser cutting ideal for continuous or large-scale manufacturing.

Material optimization: Advanced laser nesting techniques help minimize scrap and reduce material costs. This not only improves profitability but also contributes to more sustainable and eco-efficient production processes.

Superior edge quality: Tube laser cutting provides clean, burr-free finishes that often eliminate the need for secondary machining or polishing operations. This improves the final product’s fit, appearance, and assembly performance.

These combined benefits make tube laser cutting an essential process for manufacturers seeking accuracy, efficiency, and scalability. Whether for structural components, industrial frames, or custom metal parts, this technology ensures reliable performance and consistent quality across every production stage.

Sustainable and Cost-Effective Production

At SUMIPARTS, sustainability is integral to our production strategy. Our tube laser cutting systems are designed to reduce waste, energy consumption, and emissions without compromising performance.

By implementing optimized machining parameters and digital process simulation, we improve cutting efficiency while extending tool life and minimizing scrap generation. This commitment to sustainability helps our clients achieve a lower total cost of ownership and contributes to more environmentally responsible manufacturing.

Furthermore, our continuous investment in automation and process monitoring ensures repeatability and quality across every production cycle — aligning technological innovation with ecological awareness.

Quality, Innovation, and Integration

Our commitment to quality is reflected in every stage of production. At SUMIPARTS, all components are manufactured under ISO and ASTM-compliant quality assurance systems. From prototype development to high-volume runs, we apply dimensional verification, performance testing, and traceability protocols that guarantee reliability and consistency.

Through the integration of CAD/CAM software, CNC automation, and advanced laser systems, we ensure seamless transition from design to production. This digital workflow enhances accuracy, reduces lead times, and allows for flexible adaptation to complex projects.

When combined with our complementary services — such as CNC turning, milling, and welding — tube laser cutting becomes part of a comprehensive manufacturing solution that supports every client’s needs, from custom designs to mass production.

SUMIPARTS SAS has an experienced team of personnel, who with their knowledge and skills can provide an excellent service and final product tailored to needs.

If you want to know more about LASER CUTS IN METAL TUBES, at SUMIPARTS SAS we will be in the best position to collaborate. We want to provide you with the best services at your fingertips.

Get in touch with us by calling Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click aquí , or by sending an email to info@sumiparts.us. Our technical team will be ready to assist you. , we leave you some links that may be of your interest Machining Line

- sheet metal laser cutting service

- metal cutting lasers

- laser cutting

- tubelaser

- tube laser cutting