Understanding Shear Cutting of Stainless Steel

Shear cutting is one of the most efficient methods for processing stainless steel, a durable and corrosion-resistant metal widely used in industrial and commercial applications. The process involves applying a high-pressure blade to slice through metal sheets cleanly, producing straight, precise edges without excessive distortion.

Unlike laser or plasma cutting, shear cutting is particularly well-suited for thicker sheets and high-volume production, offering speed and repeatability while minimizing waste. Industries such as automotive, construction, kitchen equipment, and medical manufacturing rely on this technique to produce high-quality stainless steel components efficiently.

How Shear Cutting Works

In shear cutting, the stainless steel sheet is positioned between a stationary bottom blade and a moving top blade. The moving blade applies sufficient force to cut through the material cleanly. Modern CNC shearing machines allow operators to adjust cutting angles, blade clearance, and back gauges for precise dimensions.

The cutting process generates minimal heat, helping maintain the structural integrity and surface finish of the stainless steel. Operators can cut straight lines or patterns with high repeatability, making shear cutting a cost-effective solution for producing components that meet strict engineering specifications.

Challenges and Considerations

Although stainless steel is tough and corrosion-resistant, its high tensile strength can make cutting challenging if proper techniques are not used. Blade quality, clearance, and maintenance are critical to prevent burring or edge deformation.

Lubrication and careful material handling can reduce wear on the equipment and improve edge quality. In addition, thicker sheets or harder grades of stainless steel may require specialized blades or incremental cutting to achieve consistent results. Addressing these considerations ensures both efficiency and precision in high-volume production environments.

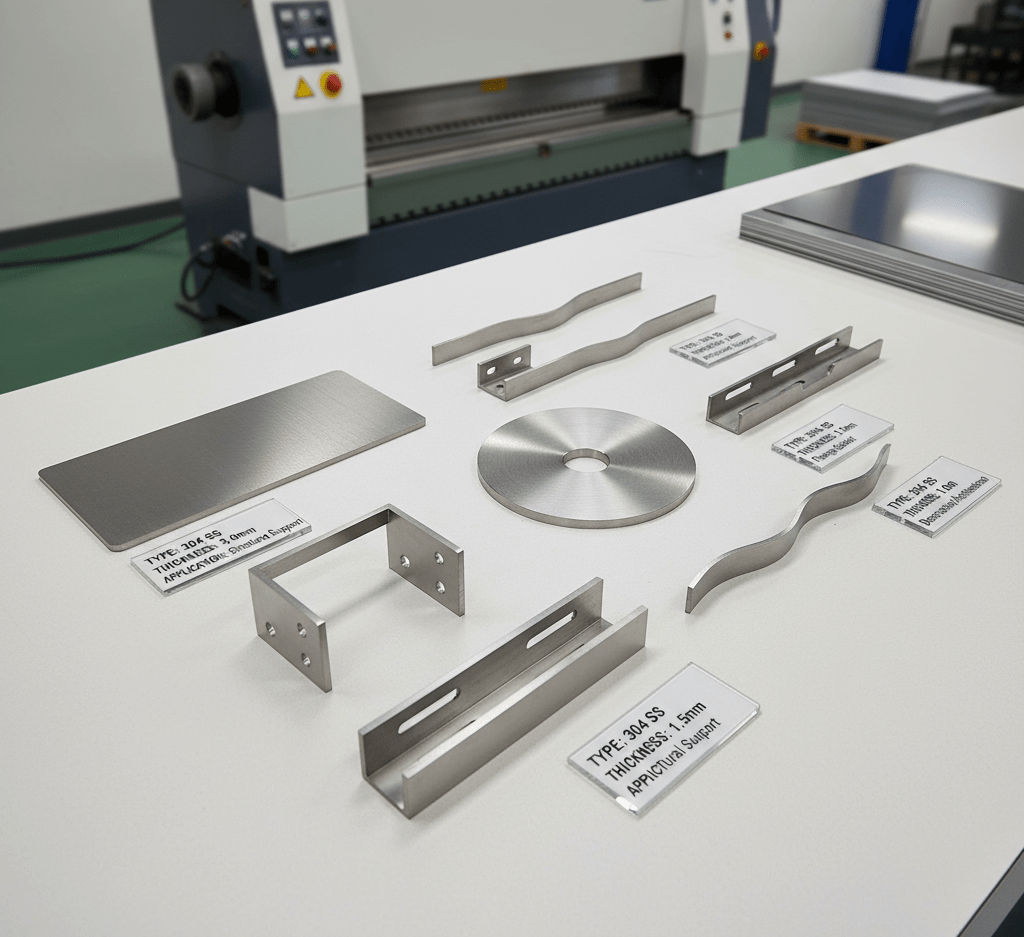

Applications of Shear Cutting Stainless Steel

Shear cutting is widely used across multiple industries due to its strength, hygiene, and corrosion resistance. Common applications include:

Kitchen and food equipment, such as countertops, panels, and trays

Architectural panels and cladding for commercial buildings

Automotive components, including brackets and reinforcements

Medical devices and cleanroom fixtures requiring smooth edges and corrosion resistance

Industrial enclosures and machinery parts demanding consistent thickness and durability

This versatility makes shear cutting a fundamental technique in modern manufacturing, ensuring quality and precision in diverse applications.

Benefits and Practical Advantages

Manufacturers choose shear cutting for its combination of speed, accuracy, and cost-effectiveness. Key advantages include:

High precision with minimal distortion, maintaining dimensional accuracy

Smooth, clean edges reducing the need for additional finishing

Efficient high-volume production, ideal for repeated components

Material optimization, minimizing waste with narrow cutting gaps

Versatility, allowing cutting of various stainless steel grades and thicknesses

Durability of tooling, especially with modern CNC-controlled blades

In addition to these benefits, shear cutting enhances operational efficiency by reducing setup times, minimizing tool wear, and limiting manual handling. This ensures consistent quality and repeatability, making it a preferred choice for industrial manufacturing where performance and visual quality matter.

Conclusion and Next Steps

Shear cutting stainless steel combines mechanical precision, reliability, and productivity to produce high-quality components across industries. Its ability to handle thick sheets and maintain clean edges makes it indispensable for structural and decorative applications alike.

To maximize results, partner with a machining expert familiar with shear cutting techniques, who can optimize blade settings, CNC parameters, and workflow. With proper expertise, shear cutting delivers efficient production, minimal waste, and durable components that meet both engineering and aesthetic standards. Our cutting service by Sumiparts SAS, allows us to obtain high precision cuts for different industrial lines, art, architecture or design projects.

One of the Sumiparts premises, in the Shear Cutting service, is that the plans and measurements have been confirmed between the client and our specialists.

That is why the service is always advised by our Engineers team in our offices, and the use of digital drawings is required for the CNC Shear Cutting service or other CNC industrial processes.

If you want to know more about this service Cut By Shear, in SUMIPARTS we will be in the best disposition to collaborate. We want to provide you with the best services at your fingertips. Get in touch with us by calling Pbx: +57 748 22 13, Cel: (+57) 313 699 13 56 or by sending an email to info@sumiparts.com . Our technical team will be ready to assist you.