Types of Molds Used in Modern Injection Molding Manufacturing

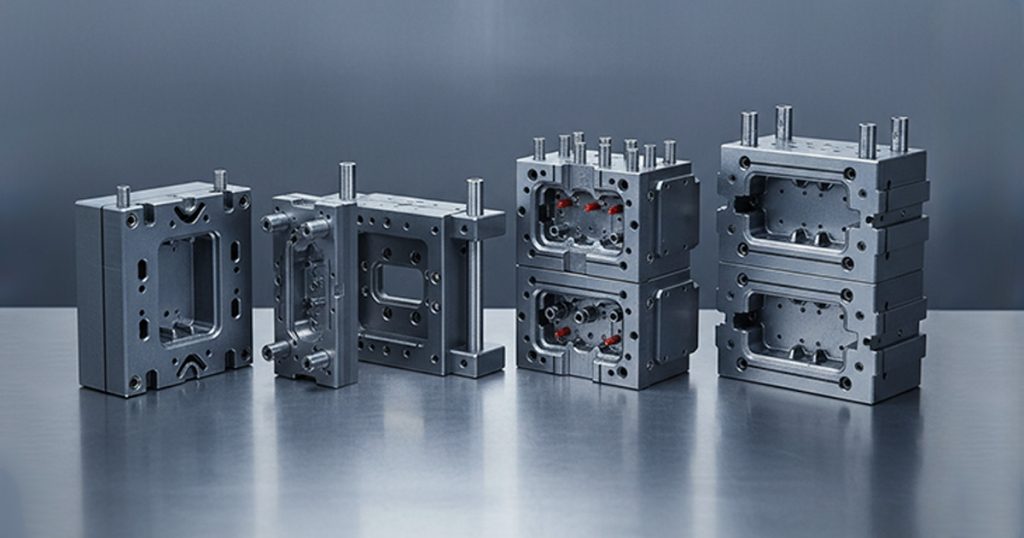

In today’s advanced manufacturing environment, understanding the different Injection Molding Mold Types is essential for achieving high precision, optimizing cycle times, and reducing production costs. Mold selection directly influences product quality, durability, the complexity of final parts, and the long-term profitability of any molding operation. As industries push for faster, more efficient, and more reliable production, mold engineering has become a core pillar of industrial manufacturing.

Injection molds are sophisticated tools designed to shape molten plastic into final products with extreme accuracy. These molds vary significantly depending on the production volume, the geometry of the part, the type of resin, and the requirements of the end-use application. A well-designed mold not only improves manufacturing efficiency but also reduces scrap, extends tooling lifespan, and ensures consistent dimensional performance.

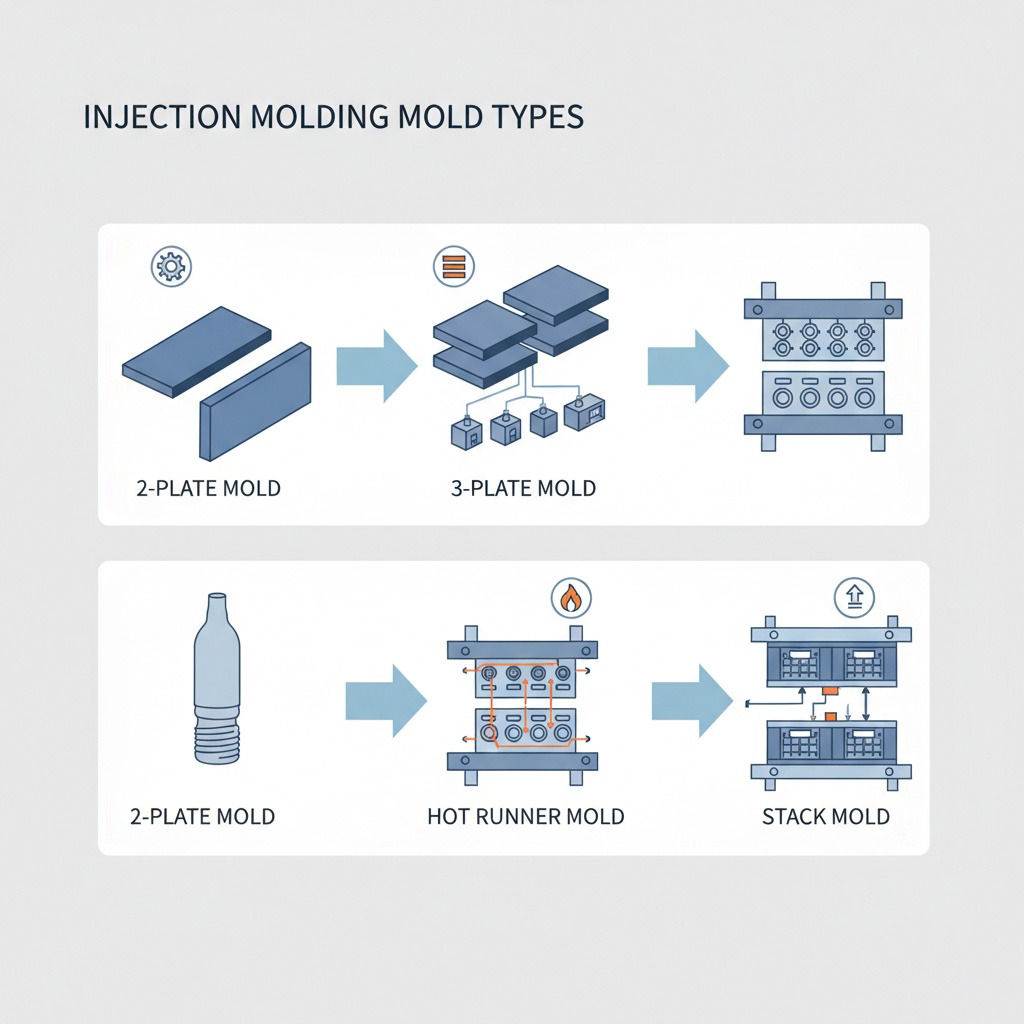

1. Two-Plate and Three-Plate Molds: The Foundation of Industrial Molding

Among the most widely used Injection Molding Mold Types are two-plate and three-plate molds. These fundamental designs form the backbone of the industry due to their reliability, versatility, and ability to handle countless plastic components across multiple sectors.

Two-Plate Molds

These molds are composed of a cavity side and a core side. They are simple, cost-effective, and ideal for high-volume production. Their streamlined construction allows molten plastic to enter the cavity through a sprue and runner system. The design is easy to maintain and provides excellent durability, making it the preferred option for general-purpose components.

Three-Plate Molds

Three-plate molds introduce an additional plate, separating the parting lines and improving gate placement flexibility. This allows engineers to inject material at optimal locations, improving surface finish and ensuring more uniform filling in complex geometries. They are especially valuable for components requiring cosmetic quality, thin walls, or multiple gating points.

Both designs remain indispensable due to their balance of cost, efficiency, and robust performance in demanding industrial environments.

2. Hot Runner and Cold Runner Molds: Choosing Efficiency

Another essential differentiation among Injection Molding Mold Types lies in the runner system. The choice between hot runner and cold runner mold technology significantly influences cycle time, energy consumption, and material usage.

Cold Runner Molds

Cold runner molds rely on channels that cool and solidify along with the part. Although cost-effective and simple to maintain, they generate additional material waste that must be trimmed or re-ground. They are excellent for short production runs or materials sensitive to heat.

Hot Runner Molds

Hot runner molds maintain the plastic resin in a molten state within heated channels. This reduces material waste and improves cycle times by eliminating the need to cool runners. Hot runner technology also increases flow control, enabling highly detailed parts, longer flow lengths, and superior surface finishes. These molds are ideal for high-volume production and applications requiring tight tolerances.

Selecting the correct runner system can determine long-term efficiency, especially when part geometry and material behavior are taken into account.

3. Family, Multi-Cavity, and Stack Molds: Maximizing Output

To meet rising demand and shorten delivery times, manufacturers rely on mold designs optimized for productivity. Injection Molding Mold Types such as family molds, multi-cavity molds, and stack molds play a crucial role in modern production. These types of injection molds allow companies to scale output efficiently while maintaining consistent part quality, stable cycle times, and reliable performance. By understanding how each injection molding mold type functions, manufacturers can select the best tool to reduce costs and improve operational efficiency.

Family Molds

Family molds, one of the most versatile Injection Molding Mold Types, produce several different parts in a single molding cycle. This makes them ideal for assemblies where multiple components must be manufactured together—consumer goods, device housings, mechanical fittings, and multi-part plastic assemblies. Using this type of injection mold ensures uniform color, dimensional accuracy, and consistent resin properties across all parts. Additionally, family molds reduce overall cycle time and tooling costs, making them a strategic choice for companies seeking high efficiency with diverse components.

Multi-Cavity Molds

When manufacturers need large volumes of identical parts, multi-cavity molds become essential. This injection molding mold type multiplies the number of parts produced in each cycle, dramatically increasing output. As one of the most common types of injection molds used in high-volume manufacturing, multi-cavity tools require perfect cavity balancing, thermal stability, and high-precision machining. Proper design prevents defects, dimensional shifts, and uneven filling—issues that are common when this type of injection molding mold is not optimized. With the right engineering, multi-cavity molds deliver exceptional productivity and consistent quality.

Stack Molds

Stack molds are advanced Injection Molding Mold Types designed to maximize productivity without increasing machine footprint. By adding vertical layers of mold cavities, these tools can double or even triple part output. This type of injection mold is ideal for thin-wall packaging, medical-grade plastics, and consumer products where high throughput is critical. Although stack molds involve greater engineering complexity, their output-to-space efficiency is unmatched in the injection molding industry. For manufacturers seeking to increase volume without investing in larger machinery, stack molds offer one of the most powerful solutions among all injection molding mold types.

4. Specialized Molds for Advanced Applications

Modern manufacturing demands highly specialized molds designed for unique applications and high-performance requirements.

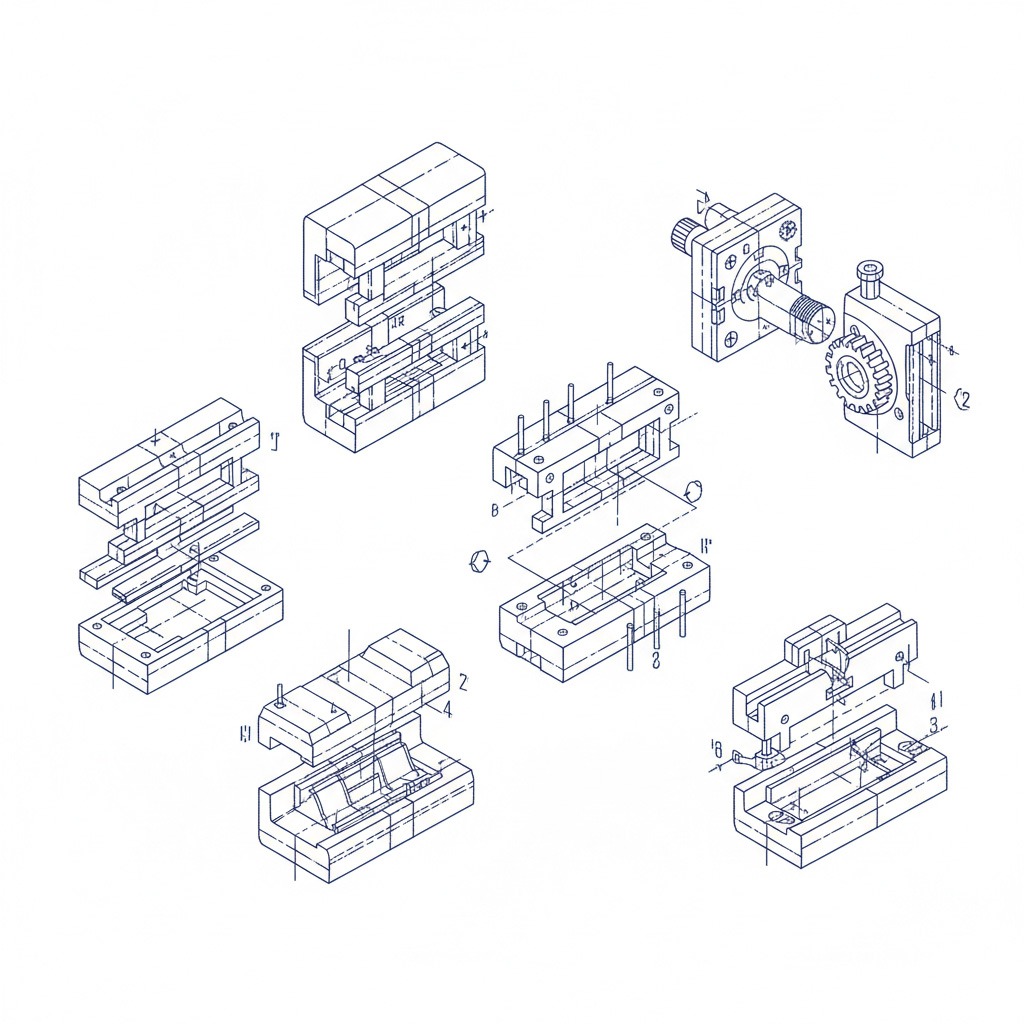

Insert Molds

Insert molding incorporates metal or threaded inserts directly into the molded part, improving strength and functionality. They are widely used in automotive, electronics, and industrial components.

Overmolding Molds

These molds allow engineers to combine multiple materials in a single cycle, creating ergonomic grips, sealed surfaces, vibration-dampening parts, and color accents. Overmolding is essential for tools, medical devices, and consumer products.

Unscrewing Molds

Parts requiring internal or external threads rely on unscrewing mechanisms, which include rotating cores or servo-driven systems. These molds ensure perfect thread formation and high durability.

Gas-Assisted Molds

Used for lightweight structures, these molds inject gas into the molten plastic, reducing sink marks, warpage, and material usage.

Conclusion

Understanding the full spectrum of Injection Molding Mold Types is crucial for optimizing manufacturing efficiency, reducing production costs, and achieving world-class quality. From simple two-plate molds to advanced stack and overmolding systems, each mold design serves a specific purpose within modern industrial applications. As manufacturing technologies continue evolving, mold engineering will remain at the center of innovation, enabling companies to create stronger, lighter, and more complex components across every sector.

Got questions? Go to our Contact Us page and send us a message — we’re here to help.