Mold Design for Plastic Injection Manufacturing

At Sumiparts SAS, we specialize in mold design and engineering for plastic injection manufacturing, ensuring every mold we produce meets the highest standards of precision, durability, and performance. We understand that mold quality directly determines the final product’s accuracy, surface finish, and production efficiency — which is why we combine advanced design tools with expert craftsmanship to achieve exceptional results.

Our plastic injection mold design service integrates innovation, technical knowledge, and modern software to support clients from concept to production. Each mold is carefully analyzed to optimize geometry, material flow, and cooling systems, reducing production time and minimizing material waste.

Our Mold Design Capabilities

At Sumiparts SAS, we offer a comprehensive range of mold design capabilities, including:

-

CAD/CAM Design Mastery: Using advanced CAD/CAM software, we create 3D models and machining programs that guarantee dimensional accuracy and mold consistency.

-

Product Optimization: We analyze part geometry, wall thickness, and flow patterns to ensure efficient filling and superior mechanical performance.

-

Reverse Engineering: Our team can recreate or improve existing molds by scanning and analyzing components to enhance efficiency and extend mold life.

-

Collaborative, Unique Designs: We work closely with our clients to design molds tailored to specific production requirements, enabling greater innovation and design flexibility.

By combining engineering expertise with cutting-edge technology, Sumiparts SAS enables customers to develop innovative plastic components and complex geometries with confidence. Our tools and simulation processes help anticipate design challenges, optimize part performance, and ensure flawless plastic injection molding results.

With every project, we reinforce our commitment to precision, quality, and innovation — delivering molds that guarantee consistent, efficient, and high-quality production for our clients across all industrial sectors.

Mold Making for Plastic Injection Manufacturing

At Sumiparts SAS, we specialize in mold making for plastic injection manufacturing, offering complete solutions that guarantee durability, precision, and efficiency in every project. Our experience in plastic injection mold production allows us to create molds that meet the highest standards of quality and performance, ensuring consistent and reliable manufacturing results.

We design and manufacture a wide variety of plastic injection molds, ranging from single-cavity to multi-cavity systems, tailored to the specific requirements of each client. Our molds can be equipped with hot runner systems, optimized cooling channels, and variable sizes and weights, depending on the complexity of the part and production volume.

Each mold produced at Sumiparts SAS undergoes a meticulous design and fabrication process. We use advanced CAD/CAM software and high-precision CNC machining centers — including CNC turning and milling machines — to guarantee accuracy in every detail, from the initial mold base to the final finishing stage. This ensures tight tolerances, excellent surface finishes, and superior mechanical performance in the injection process.

Our mold making process combines engineering expertise, tooling experience, and modern manufacturing technology to create molds capable of withstanding continuous high-volume production while maintaining optimal efficiency. We also perform dimensional inspections and test runs to validate mold performance before delivery, minimizing downtime and ensuring smooth integration into our clients’ production lines.

In addition, Sumiparts SAS provides customized mold maintenance and repair services, helping extend the lifespan of molds and ensuring consistent product quality over time. Whether you require a prototype mold or a large-scale production tool, our team delivers solutions designed to enhance plastic manufacturing productivity and reduce overall production costs.

With Sumiparts SAS, you can count on a comprehensive mold making service — from conceptual design and 3D modeling to final assembly and validation — all under strict quality control standards. Our commitment to precision and innovation allows us to deliver world-class plastic injection molds that meet the demands of today’s global industries.

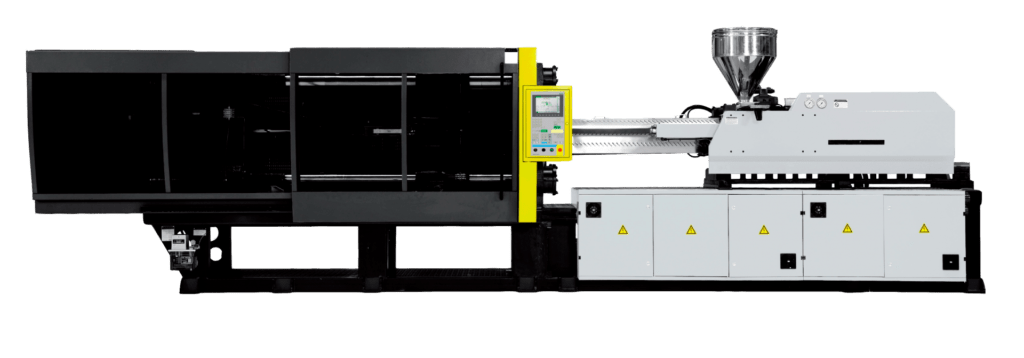

Our machines and production lines are fully equipped to manufacture any type of plastic product, operating 24/7 under a strict quality control system. We ensure excellent finishes, high-quality materials, and large production volumes.

Our integrated processes provide flexible solutions from design to production, allowing us to meet any customer requirement efficiently.

Contact us at +57 748 22 13, mobile +57 313 699 13 56 (WhatsApp) click here, or info@sumiparts.us. Our technical team is ready to assist you.