Precision and Strength for Industrial Applications

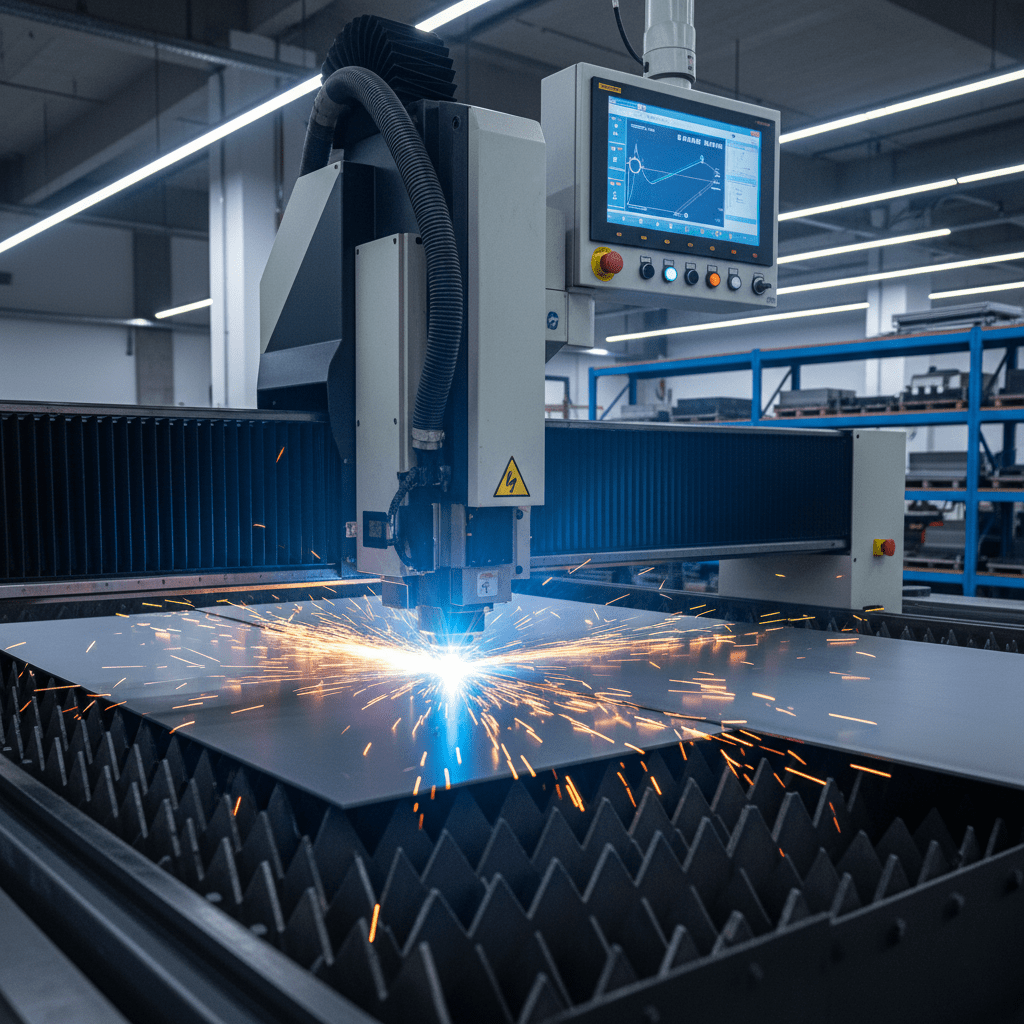

At Sumiparts SAS, we provide professional Laser Cutting services with the highest precision technology, designed for all types of materials, particularly carbon steel and industrial metals. Our Laser Cutting process ensures exact, clean, and consistent cuts, producing components that meet the most demanding technical and aesthetic standards.

The Laser Cutting service at Sumiparts SAS is an ideal solution for your business or industry. This technology allows us to deliver parts and products with superior edge quality, fast delivery times, and optimized production costs, enhancing both efficiency and profitability for our clients.

Contact us by calling +57 748 22 13, mobile +57 313 699 13 56, or by emailing info@sumiparts.com. Our technical team will be happy to assist you.

Advantages of Laser Cutting in Carbon Steel

The use of Laser Cutting in carbon steel components provides numerous advantages that make it one of the most efficient and precise manufacturing technologies available today. This process delivers high dimensional accuracy, making it ideal for producing components with complex geometries and tight tolerances. The precision of the laser beam ensures clean, burr-free edges, which minimizes the need for additional finishing or post-processing, saving both time and operational costs.

Another key advantage of Laser Cutting is its ability to support fast production cycles while maintaining material efficiency. Thanks to the focused energy of the laser, cutting speeds are significantly higher compared to traditional mechanical methods, resulting in improved throughput and reduced production times. Additionally, by minimizing waste during the cutting process, manufacturers can optimize raw material usage — a critical factor in sustainable and cost-effective production.

Consistency and repeatability are also defining characteristics of Laser Cutting, especially in large-scale industrial manufacturing. The process ensures that every part produced matches exact specifications, batch after batch, guaranteeing uniformity and reliability in mass production. Furthermore, the technology offers outstanding design flexibility, enabling the creation of detailed patterns, intricate contours, and customized designs that expand the creative and functional possibilities for engineers and designers.

At Sumiparts SAS, we integrate state-of-the-art laser systems with advanced CAD/CAM programming to deliver precise, efficient, and high-quality results. This digital integration allows for optimal nesting of parts, maximum material utilization, and streamlined workflows, ensuring that every project achieves the perfect balance between technical performance and cost efficiency. Our experienced team supervises each stage of the process to guarantee excellence, precision, and reliability — key attributes that define Sumiparts SAS as a trusted leader in modern Laser Cutting solutions.

Why Carbon Steel is Ideal for Laser Cutting

As its name suggests, carbon steel is an alloy whose main element is carbon, combined with other essential components such as iron, silicon, magnesium, and phosphorus. This chemical composition provides the material with exceptional mechanical strength, formability, and durability, making it one of the most commonly used steels in the manufacturing industry.

Carbon steel is widely known as construction steel, representing a significant portion of the steels produced in global steel mills. It has been classified separately from other types of steels—such as stainless, tool, or electrical steels—due to its distinctive balance between strength, machinability, and cost-effectiveness.

Under the general concept of carbon steel for construction, we can also include steels used in civil engineering, mechanical structures, and industrial fabrication, all of which benefit greatly from the precision and efficiency offered by Laser Cutting technology.

Laser Cutting for Modern Industry

Our Laser Cutting service represents one of the most advanced and efficient manufacturing processes available today, delivering exceptional precision, clean edges, and consistent results across a wide variety of materials. This technology has become a key tool in modern industry, supporting both large-scale production and custom manufacturing needs.

At Sumiparts SAS, our Laser Cutting process is applied in sectors such as construction, automotive, architecture, mechanical assembly, and metal fabrication — industries that demand tight tolerances, repeatable results, and durable performance. Through our commitment to process optimization and advanced technology, we ensure every component meets exact technical specifications and aesthetic requirements.

Beyond cutting accuracy, our service also enables greater design flexibility, allowing complex geometries, fine details, and intricate contours that would be difficult or impossible to achieve through traditional cutting methods. This versatility supports innovative engineering solutions and reduces the need for secondary machining or finishing operations, improving both production speed and cost efficiency.

By integrating this process into our operations, Sumiparts SAS consolidates its role as a trusted partner for industries seeking dependable manufacturing support. Our focus remains on continuous improvement, ensuring that every laser-cut component delivers high quality, reliability, and performance that stands the test of time.