Stainless Steel Turning

At SUMIPARTS, we specialize in high-precision turning of stainless steel components, delivering exceptional mechanical performance and corrosion resistance. Thanks to our advanced CNC technology and experienced engineering team, we produce complex geometries and flawless surface finishes for demanding industrial applications.

Properties and Advantages of Stainless Steel

Stainless steel is one of the most versatile and durable materials in modern manufacturing. It offers excellent resistance to oxidation, high tensile strength, and low maintenance needs, making it ideal for environments exposed to heat, moisture, or chemicals.

Its mechanical stability allows for precise machining, while its clean, aesthetic finish makes it a preferred choice in industries such as automotive, food processing, petrochemical, and construction. The combination of hardness and corrosion resistance guarantees longer part lifespan and lower replacement costs.

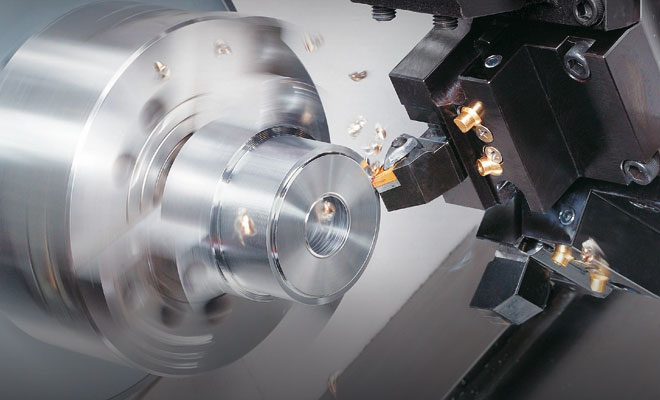

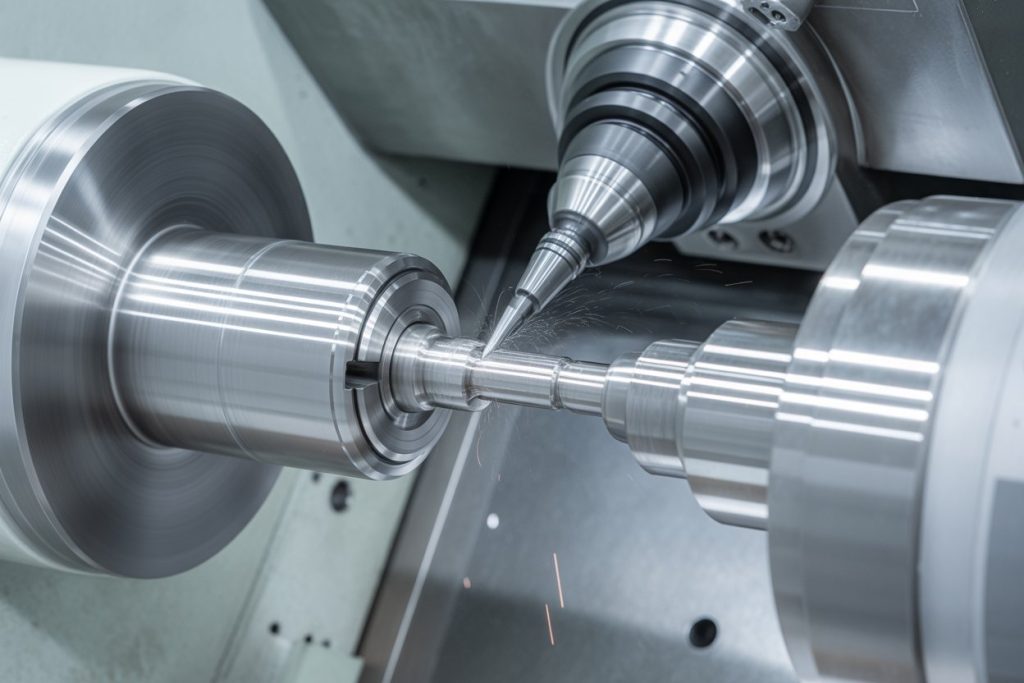

CNC Turning Process for Stainless Steel

At SUMIPARTS, our CNC turning process relies on state-of-the-art multi-axis lathes designed to achieve exceptional levels of precision, efficiency, and consistency. By integrating advanced CAD/CAM software, we convert digital 3D models into tangible components with exact geometries and flawless finishes. This digital workflow allows for seamless coordination between design and production, ensuring that every part meets strict dimensional and performance specifications.

Each stage of the process — from initial material setup to the final finishing — is closely monitored using high-resolution sensors and automated measuring systems. These technologies maintain tolerance levels within microns, guaranteeing repeatability even in complex or large-scale production runs. This not only reduces human error but also optimizes cutting speeds, tool paths, and material utilization, resulting in greater productivity and cost efficiency.

Our CNC turning operations are supported by a skilled engineering team that supervises every adjustment and calibration required to achieve consistent results. The combination of precision machinery, advanced software, and rigorous process control ensures superior surface finishes and the long-term reliability of every part we produce.

Industrial Applications

Stainless steel turning plays a fundamental role in multiple industries that require materials with high resistance, precision, and long service life. Its versatility and excellent mechanical performance make it a preferred option for producing complex components in demanding environments.

In the automotive industry, turned stainless steel parts such as shafts, bushings, couplings, and precision fittings are widely used for their ability to withstand friction, vibration, and continuous mechanical stress. These components are crucial for maintaining vehicle reliability and performance over time.

In the food and pharmaceutical sectors, stainless steel turning enables the manufacture of hygienic-grade components, sanitary fittings, and containers that comply with strict regulations for cleanliness and corrosion resistance. This ensures safe handling of products and long-lasting performance under constant sterilization or exposure to chemicals.

In construction and infrastructure, stainless steel components such as fasteners, supports, and mechanical joints provide structural stability and resistance to weathering and corrosion. Their durability makes them ideal for bridges, high-rise buildings, and mechanical systems exposed to moisture or environmental stress.

The oil and gas industry also relies heavily on stainless steel turning for the production of high-precision valves, seals, and structural components that must endure extreme pressures, temperatures, and corrosive conditions. These parts are critical to maintaining safety and reliability in energy and extraction systems.

At SUMIPARTS, every stainless steel component is produced under strict quality control protocols and in compliance with international standards. Our advanced machining processes, combined with expert engineering and precise inspection methods, ensure that each piece delivers maximum performance, safety, and operational efficiency throughout its lifespan.

Commitment to Quality and Innovation

Quality control is integrated into every stage of our stainless steel turning operations. Using ISO-compliant processes, we perform dimensional inspection, surface roughness evaluation, and hardness testing to ensure precision and consistency.

At SUMIPARTS, we constantly invest in automation and innovation — including high-speed lathes, precision measuring systems, and sustainable machining practices — to remain at the forefront of industrial manufacturing technology.

If you’d like to learn more about our stainless steel turning service, SUMIPARTS is happy to assist you. We want to provide you with the best services at your fingertips. Contact us by calling +57 748 22 13 or +57 313 699 13 56, or by emailing info@sumiparts.com. Our technical team will be ready to help you.