How the Laser Cutting Process Works

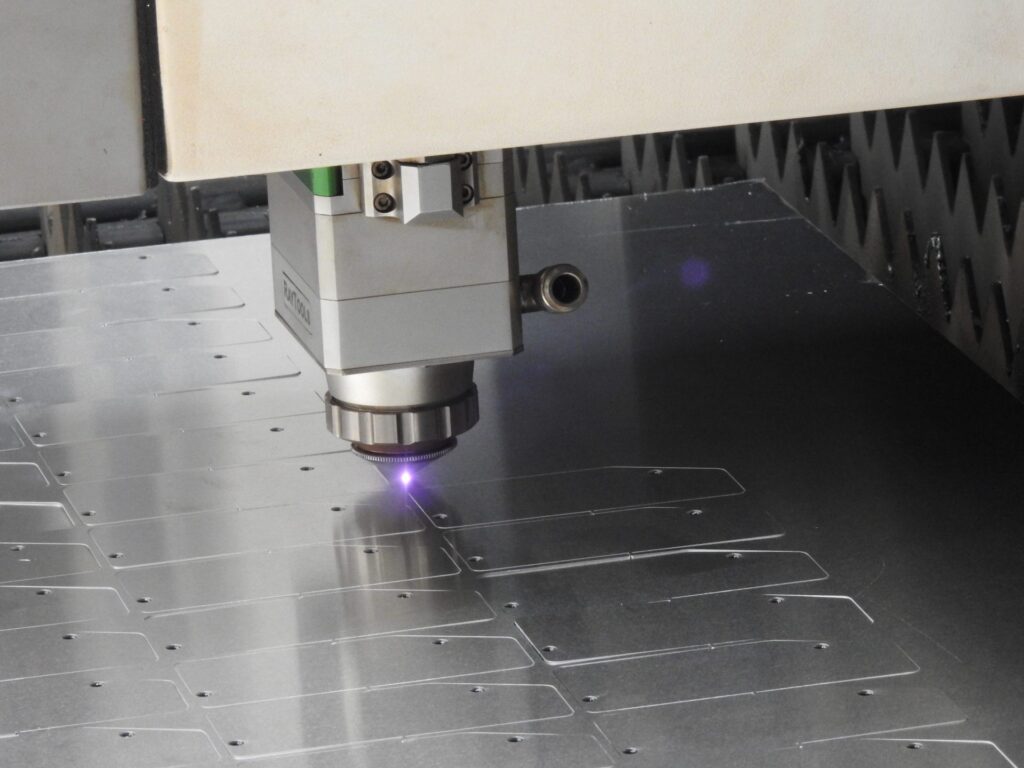

During laser cutting, a high-energy beam is directed onto the aluminium surface through optical lenses. The focused heat melts or vaporizes the material in a narrow path, while a stream of gas — typically nitrogen or oxygen — removes molten residues. This combination ensures clean edges and fast processing speeds.

Modern CNC laser machines can follow complex cutting paths directly from digital designs, eliminating the need for tooling and reducing setup time. Parameters such as laser power, cutting speed, and gas pressure are carefully adjusted to prevent oxidation and ensure optimal results across different aluminium thicknesses.

Challenges and Solutions in Aluminium Laser Cutting

Although aluminium is highly reflective and thermally conductive, advanced laser systems have overcome many of these challenges. Fiber lasers, in particular, are designed to handle reflective metals safely, converting energy efficiently and minimizing beam reflection.

Proper focus control, assist gas selection, and machine calibration are essential to maintain edge quality and avoid burr formation. Additionally, using protective coatings or specialized nozzles can enhance performance when working with thin or polished aluminium sheets.

These innovations have made aluminium laser cutting faster, safer, and more reliable than ever before.

Key Applications Across Industries

Aluminium laser cutting is used in a wide variety of fields thanks to its balance of precision and productivity. Some of the most common applications include:

Automotive components, such as brackets, covers, and trim pieces

Architectural panels and decorative facades requiring detailed designs

Electronic housings and lightweight structural parts

Aerospace components demanding tight dimensional control

Custom signage and branding elements with smooth, polished finishes

Each of these applications benefits from the accuracy and repeatability of laser processing, reducing post-processing needs and improving overall efficiency.

Benefits and Practical Advantages

Manufacturers choose aluminium laser cutting because it offers a combination of speed, accuracy, and cost-effectiveness that few other processes can match. The main advantages include:

Exceptional precision with minimal edge deformation, allowing components to meet tight tolerances and reducing the need for secondary finishing.

Clean, oxide-free cuts when using nitrogen or argon assist gases, producing surfaces ready for assembly or coating.

Reduced material waste, thanks to narrow kerf widths that maximize the use of aluminium sheets and minimize scrap.

High production efficiency through automated CNC control, enabling faster turnaround times and consistent output.

Design flexibility, allowing intricate geometries, complex patterns, and fine details that would be difficult or impossible with traditional cutting methods.

No physical contact, minimizing the risk of material distortion, scratches, or surface imperfections, which is especially important for polished or decorative components.

In addition to these technical benefits, aluminium laser cutting also contributes to overall operational efficiency. By reducing setup times, eliminating tool wear, and minimizing manual handling, manufacturers can lower production costs while maintaining high quality. The process is particularly valuable for high-volume production where repeatability and reliability are critical.

These features make laser processing a preferred choice for industrial manufacturing, combining performance, visual appeal, and precision. Whether for structural components, automotive parts, or architectural elements, aluminium laser cutting ensures consistent results even in complex or large-scale projects. Its combination of speed, accuracy, and flexibility allows companies to meet modern design and production demands without compromising quality.

Conclusion and Next Steps

Laser cutting in aluminium has revolutionized the way manufacturers create lightweight, durable components. Its ability to combine speed, precision, and repeatability supports industries that demand perfection in every cut.

To achieve the best performance, work with a machining partner who understands laser technology and aluminium behavior — ensuring each project meets dimensional, visual, and functional standards.

By integrating advanced laser systems and proper process control, companies can deliver products that reflect true engineering excellence and modern design.

If you’d like to learn more about our aluminum laser cutting service, SUMIPARTS is happy to help. We want to provide you with the best services at your fingertips. Contact us by calling +57 748 22 13, mobile (+57) 313 699 13 56, or by emailing info@sumiparts.com. Our technical team will be ready to assist you.