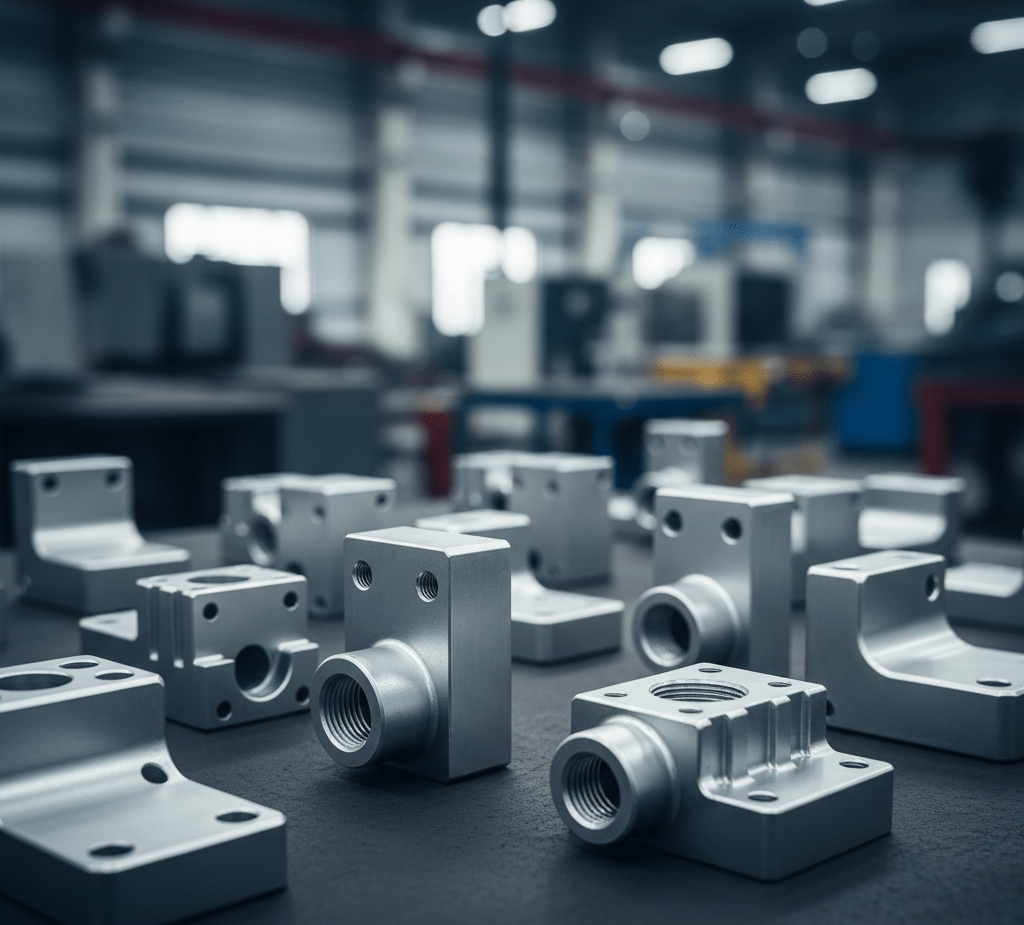

Understanding Aluminum and Zamak Injection

Aluminum and Zamak injection is a manufacturing technique used to produce durable, precise, and dimensionally consistent metal components. Both alloys — lightweight aluminum and zinc-based Zamak — offer distinct advantages that make them essential in industries requiring strength, detail, and visual quality.

Through a controlled balance of pressure and temperature, molten alloy is injected into a steel mold where it cools and solidifies. This results in a part that exhibits high accuracy, smooth surface finish, and excellent mechanical strength. The process minimizes material waste and allows for complex geometries, making it ideal for industrial and decorative applications alike.

Why Manufacturers Choose Aluminum and Zamak

The choice between aluminum and Zamak often depends on the mechanical and cost-performance ratio required.

-

Aluminum provides an outstanding strength-to-weight ratio, natural corrosion resistance, and thermal conductivity, making it suitable for demanding environments.

-

Zamak offers superior fluidity, allowing finer detail and tighter tolerances in molds.

-

Both alloys can be polished, plated, or painted, offering wide design flexibility.

Because these metals also respond well to secondary machining operations, such as CNC turning or surface finishing, manufacturers can refine their properties even further to meet exact specifications.

Technical Aspects of the Aluminum and Zamak Injection Process

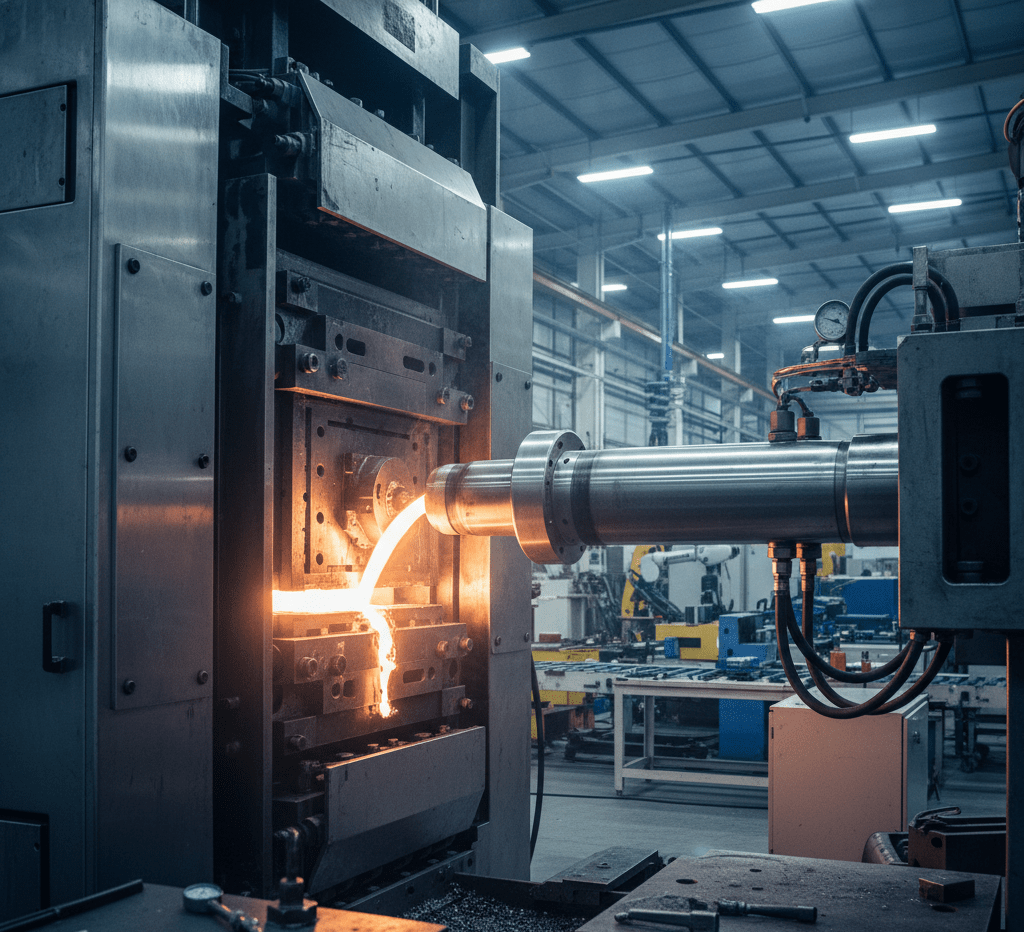

The injection of aluminum and Zamak, as well as other non-ferrous metals, shares similarities with plastic injection molding but demands far greater precision and control. The molten alloy must reach an optimal state — fluid enough to completely fill the mold cavities but stable to prevent shrinkage or porosity once cooled.

Unlike disposable molds, metal injection employs permanent molds made from high-strength tool steels capable of withstanding extreme temperatures and pressure cycles. These molds ensure consistent results, enabling large-scale production without loss of quality or accuracy.

At its core, the aluminum and Zamak injection process relies on high-pressure die casting. Molten metal is forced into the mold at pressures exceeding several thousand psi, capturing intricate details and ensuring tight tolerances. This high-pressure method represents about 50% of global light-alloy casting production, while low-pressure casting accounts for around 20%, typically used for components demanding exceptional mechanical performance.

By controlling critical parameters such as injection velocity, mold temperature, and cooling rate, manufacturers achieve the perfect balance between mechanical strength, durability, and surface quality — resulting in products that combine technical precision with a refined appearance.

Process Workflow

The aluminum and Zamak injection workflow follows several precise stages:

-

Mold preparation and lubrication to ensure clean ejection and avoid surface defects.

-

Metal melting and temperature control to maintain proper viscosity.

-

High-pressure injection for accurate filling of the mold cavity.

-

Cooling and solidification to preserve shape and structure.

-

Trimming, cleaning, and inspection for final quality assurance.

Modern automated systems guarantee consistent part geometry, even in large-scale production runs.

Benefits of Aluminum and Zamak Injection

-

High productivity: Ideal for large production volumes with minimal downtime.

-

Dimensional accuracy: Ready-to-use parts requiring little to no machining.

-

Design freedom: Supports thin walls and intricate details.

-

Sustainability: Excess alloy can be recycled repeatedly without loss of quality.

-

Superior surface finish: Enables anodized, polished, or painted appearances.

These properties make aluminum and Zamak suitable for everything from mechanical housings to decorative hardware, balancing durability and aesthetic appeal.

Inside the Aluminum and Zamak Injection Equipment

The aluminum and zamak injection equipment consists of two vertical plates in which the mold holders that hold the halves of the die are located. A fixed plate and the other has a movement for the removal of the piece.

A metered quantity of metal is poured into the container and then fed into the mold cavity using a hydraulically actuated piston.

Once the metal has solidified, the mold is opened and the injected part is removed. On this process, special precautions must be taken to avoid gas inclusions that cause blistering during heat treatment or welding of the cast product.

If you want to know more about the Zamak Injection, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.