What Makes Stainless Steel Laser Cutting Special?

Have you ever wondered how complex stainless steel parts are created with micron-level precision? Stainless steel laser cutting uses a highly focused laser beam to slice through metal without any physical contact. This produces clean, smooth edges, reduces material distortion, and allows for designs that would be impossible with traditional cutting methods.

From automotive panels to decorative architectural elements, this process is widely valued for accuracy, repeatability, and speed, making it a go-to technique for modern manufacturers.

How the Process Works

The workflow of stainless steel laser cutting can be summarized in four key steps:

-

Design preparation: CAD or digital files guide the laser path.

-

Laser application: A concentrated beam melts or vaporizes the metal.

-

Assist gas application: Nitrogen or oxygen removes molten material and prevents oxidation.

-

Inspection: Components are checked for edge quality, precision, and finish.

💡 Tip: Adjusting laser power and cutting speed according to sheet thickness ensures minimal heat-affected zones and consistent results.

Key Advantages of Laser Cutting Stainless Steel

Why do manufacturers prefer this technique? Here are the main benefits:

-

High precision: Tight tolerances and smooth edges reduce post-processing.

-

Complex geometries: CNC-controlled lasers cut shapes impossible with mechanical tools.

-

Speed and efficiency: High-volume production with minimal setup.

-

Material savings: Narrow kerf reduces scrap.

-

Non-contact process: Preserves the surface finish and structural integrity.

This combination of accuracy, flexibility, and efficiency makes it ideal for industries where both functionality and aesthetics matter.

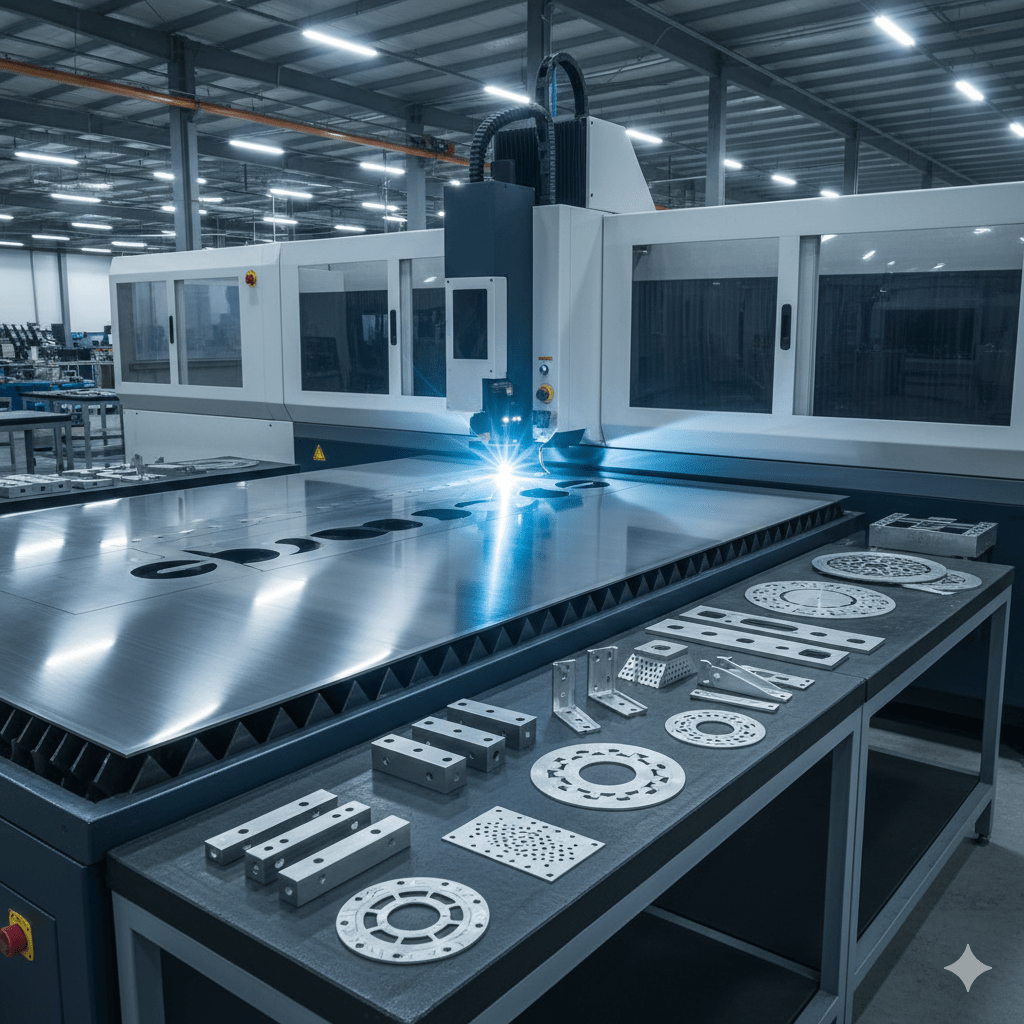

Real-World Applications

Stainless steel laser cutting is used across multiple industries:

-

Automotive: Panels, brackets, and custom trim.

-

Architecture & Interiors: Decorative facades, wall panels, railings.

-

Medical: Surgical instruments, housings, and fixtures.

-

Industrial Equipment: Enclosures, guards, and machinery parts.

-

Signage & Branding: Custom logos and engraved elements.

Each application benefits from the smooth finish, precise dimensions, and durability that only laser cutting can deliver.

Practical Tips for Optimized Results

To get the most out of stainless steel laser cutting, consider these best practices:

-

Use fiber lasers for reflective or thicker stainless steel sheets.

-

Choose the right assist gas to prevent oxidation and achieve polished edges.

-

Maintain ventilation and fume extraction for a safe and clean workspace.

-

Monitor machine calibration and blade alignment for consistent quality.

Following these tips ensures efficient, high-quality production for both prototypes and mass manufacturing.

Why Stainless Steel Laser Cutting Matters

Stainless steel laser cutting is more than a process — it’s a way to combine precision, speed, and design flexibility in one efficient workflow. From intricate decorative panels to critical industrial components, this technique allows manufacturers to deliver high-quality, durable, and visually appealing products.

Partnering with an experienced CNC laser provider ensures every project meets dimensional, functional, and aesthetic standards, maximizing efficiency and reducing waste. Whether you’re producing one-off custom parts or high-volume runs, laser cutting stainless steel ensures reliable results every time.

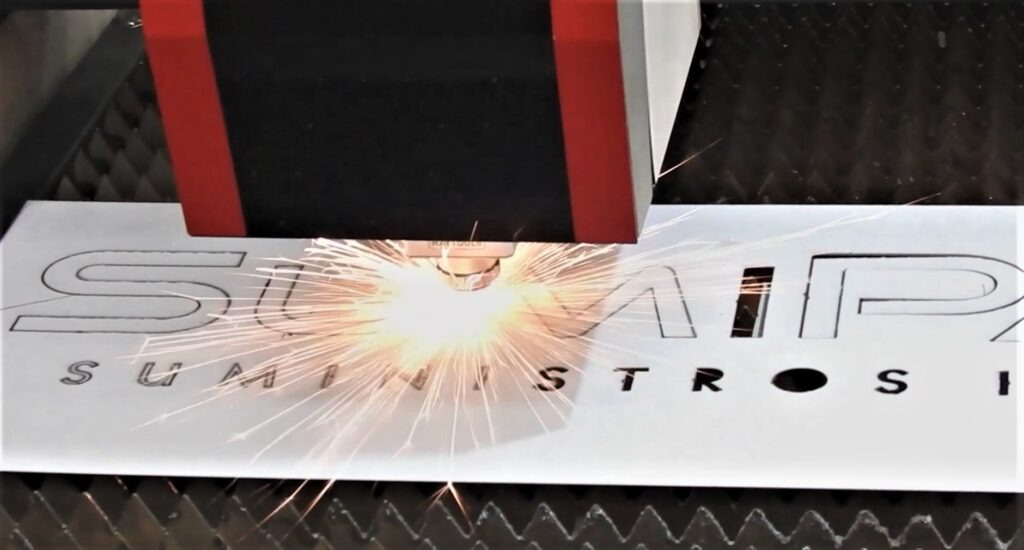

Laser cutting on stainless steel is made with high quality standards and also with good delivery time, that is what SUMIPARTS S.A.S., industrial supplies offers you. If what you are looking for is accuracy on your machined laser cutting jobs, Sumiparts is the best option.

Stainless steel laser cutting is one of SUMIPARTS ‘specialties. We carry out different types of laser cutting to make the precision machining jobs of our clients come true. Depending on the target and the part to be machined, we decide between one type of cut or another, providing the best result, it is undoubtedly the best service of laser cutting in stainless steel .

Our laser cutting system allows you to get complex pieces and the final result reaches the depth and geometry necessary for your project.

Laser vs plasma cutting

One of the most common questions is laser vs plasma . Plasma cutting is based on sending a ionized gas jet at high speed. This ionized gas is plasma , which conducts electricity from the torch to the workpiece. The plasma cutting can be applied to any type of material and no operator is required. So, if we are between plasma vs laser , the solution is to first know the objective of the machining work.

If you want to know more about the Laser Cutting Process, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.