Understanding Stainless Steel Machining

Machining stainless steel requires skill, precision, and the right equipment. Unlike mild steels, stainless alloys are harder, more elastic, and prone to work hardening. These properties make machining more challenging, but they also result in components with superior strength and corrosion resistance.

In modern manufacturing, stainless steel machining is widely used for producing durable parts in industries such as aerospace, food processing, automotive, and medical technology. Its combination of toughness and clean finish makes it a favorite for both functional and aesthetic applications.

Advanced Techniques Used in Stainless Steel Machining

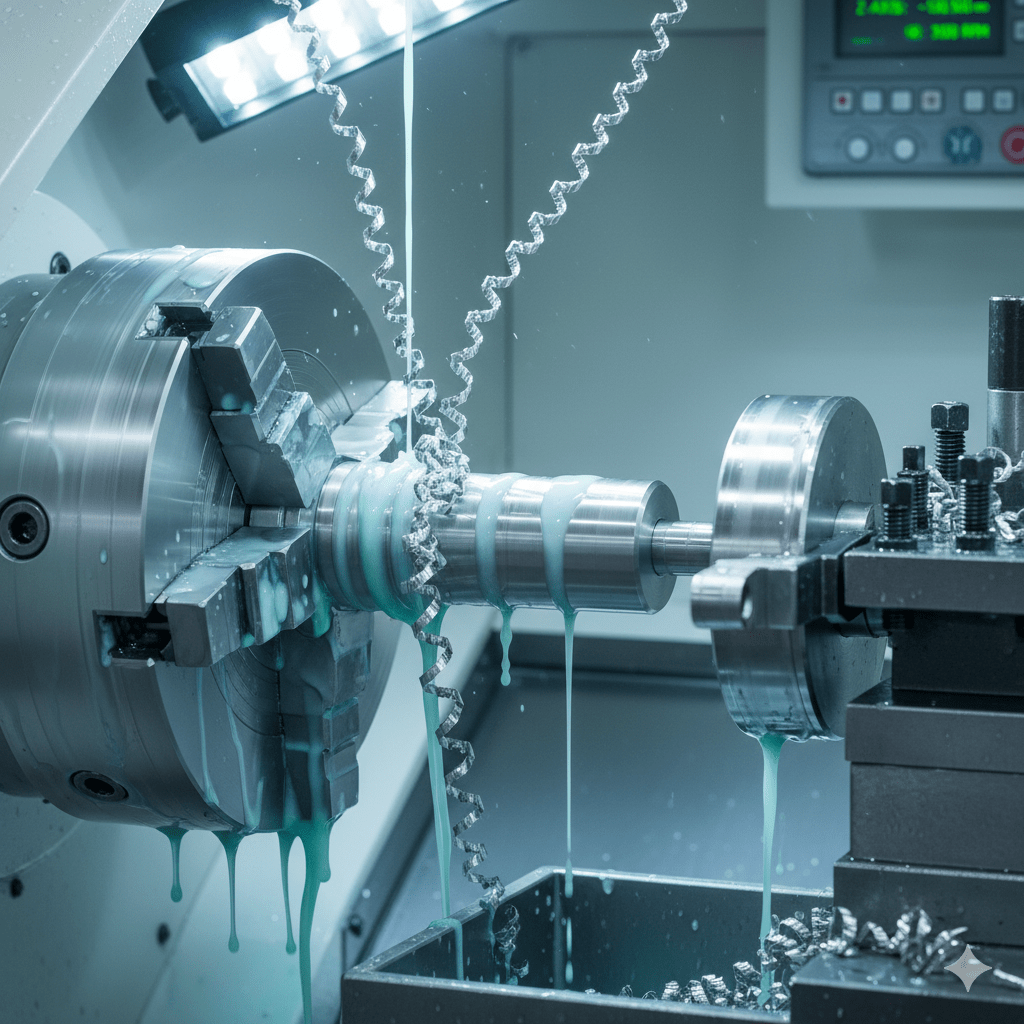

Modern machining relies heavily on CNC-controlled systems that deliver accuracy and repeatability. The main operations include:

Turning: Used to shape cylindrical parts with precise dimensions.

-

Milling: Ideal for flat or contoured surfaces with intricate geometries.

-

Drilling and tapping: Applied for holes, threads, and inserts.

-

Grinding and polishing: Used to achieve smooth or mirror-like finishes.

Each technique requires careful control of cutting speeds, feed rates, and tool selection to prevent excessive heat and premature wear. Using carbide or coated tools and proper coolant application ensures extended tool life and consistent surface quality.

Challenges and How to Overcome Them

Working with stainless steel can present several difficulties:

-

Heat generation: The alloy’s low thermal conductivity causes high temperatures at the cutting edge.

-

Work hardening: Once deformed, the surface becomes harder, requiring sharper tools.

-

Built-up edge formation: Metal adhesion on cutting tools can damage the finish.

To overcome these issues, machinists often use optimized tool geometries, flood cooling, and reduced cutting depths. Modern CNC programming allows adaptive control of these parameters to maintain stability and precision throughout the machining process.

Applications of Stainless Steel Components

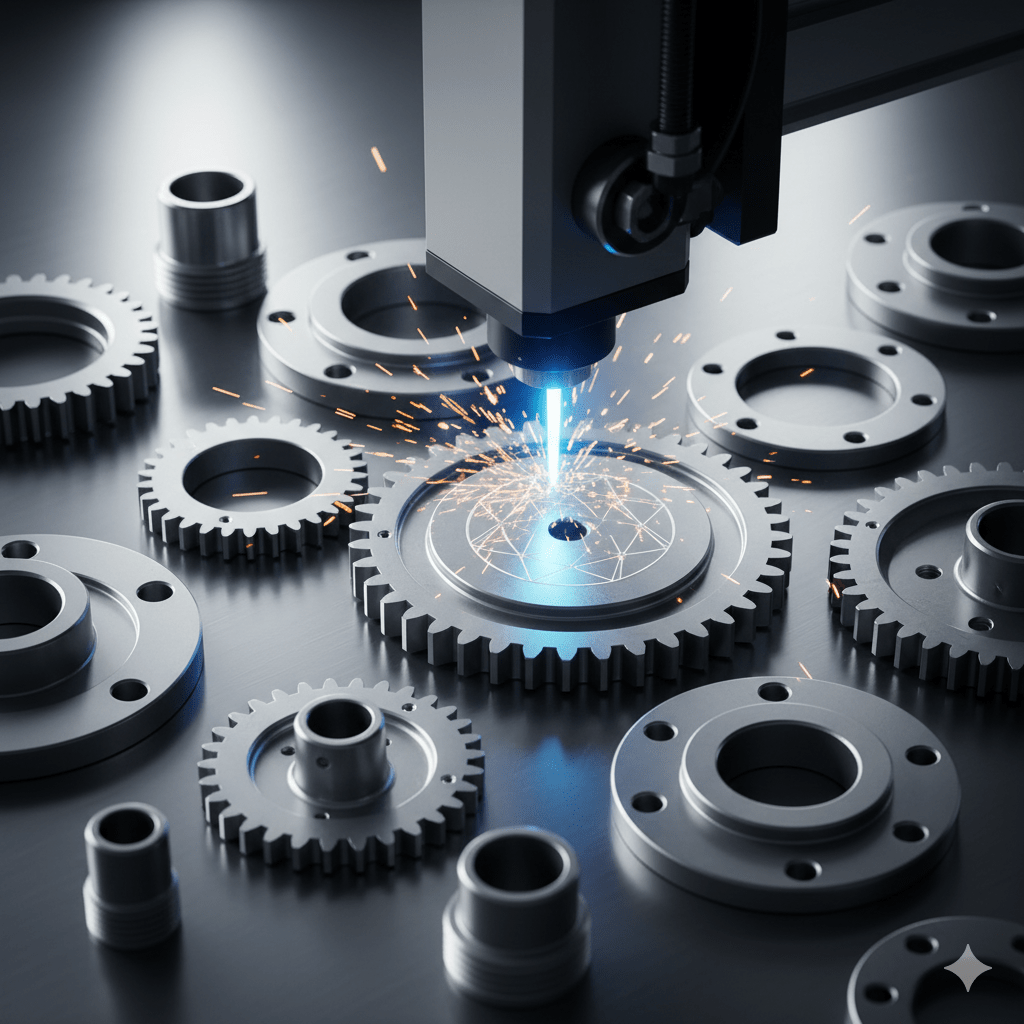

The versatility of machined stainless steel allows its use in countless products, such as:

-

Structural brackets and industrial fasteners

-

Food-grade equipment and medical instruments

-

High-performance automotive and marine parts

-

Decorative elements for architecture and furniture

These components combine durability, corrosion resistance, and excellent mechanical performance—qualities that justify the popularity of stainless steel in precision engineering.

Benefits of Stainless Steel Machining

-

Exceptional strength and longevity

-

Resistance to rust and oxidation

-

Dimensional stability under stress

-

Compatibility with surface finishing and welding

-

Clean, hygienic appearance suitable for sterile environments

Such advantages make stainless steel machining essential for sectors where reliability and precision are non-negotiable.

Quality Control in Stainless Steel Machining

Every stage of stainless steel machining must comply with strict quality standards to ensure that each component meets design and functional requirements. Precision isn’t just about accuracy — it’s about consistency, traceability, and reliability across every batch.

- Dimensional Verification

After machining, parts are inspected using CMM (Coordinate Measuring Machines), micrometers, and digital calipers to confirm that tolerances meet the customer’s specifications. Even minimal deviations can affect assembly or performance, especially in industries such as aerospace and medical manufacturing.

- Surface Integrity

The surface finish of stainless steel determines its performance and durability. Techniques such as profilometry and optical scanning help evaluate roughness and uniformity, while polishing and passivation treatments remove any residues that could affect corrosion resistance.

- Material Certification

Reputable machining facilities provide material traceability certificates, ensuring that every stainless steel grade used — whether 304, 316, or 17-4 PH — meets international standards (ASTM, ISO, or DIN). This guarantees optimal strength and resistance for the intended application.

The Role of CNC Technology in Modern Machining

CNC (Computer Numerical Control) has revolutionized stainless steel machining by combining automation with precision engineering. These systems allow multi-axis movements, automatic tool changes, and real-time monitoring of machining parameters.

With CNC technology:

-

Complex geometries can be produced in fewer steps.

-

Repeatability is ensured even in high-volume production.

-

Errors due to manual handling are significantly reduced.

-

Efficiency increases thanks to automated toolpath optimization.

When integrated with CAD/CAM software, engineers can simulate tool movements, analyze cutting forces, and predict potential deformation — saving time and materials during production.

Final Thoughts

Stainless steel machining remains one of the most demanding yet rewarding areas of modern manufacturing. The right combination of machinery, experience, and process control leads to high-precision parts capable of performing under extreme conditions.

Collaborating with an experienced machining partner ensures consistency from prototype to full-scale production — guaranteeing parts that meet the highest industry standards for quality and performance.

If you’d like to learn more about our stainless steel machining services at SUMIPARTS, we’d be happy to assist you. We strive to provide you with the best services at your fingertips. Contact us by calling +57 748 22 13 or emailing info@sumiparts.com. Our technical team will be ready to help you.

Stainless steel machining remains one of the most demanding yet rewarding areas of modern manufacturing. The right combination of machinery, experience, and process control leads to high-precision parts capable of performing under extreme conditions.

Collaborating with an experienced machining partner ensures consistency from prototype to full-scale production — guaranteeing parts that meet the highest industry standards for quality and performance.