The Manufacturing of Molds: From Concept Design to Precision Production

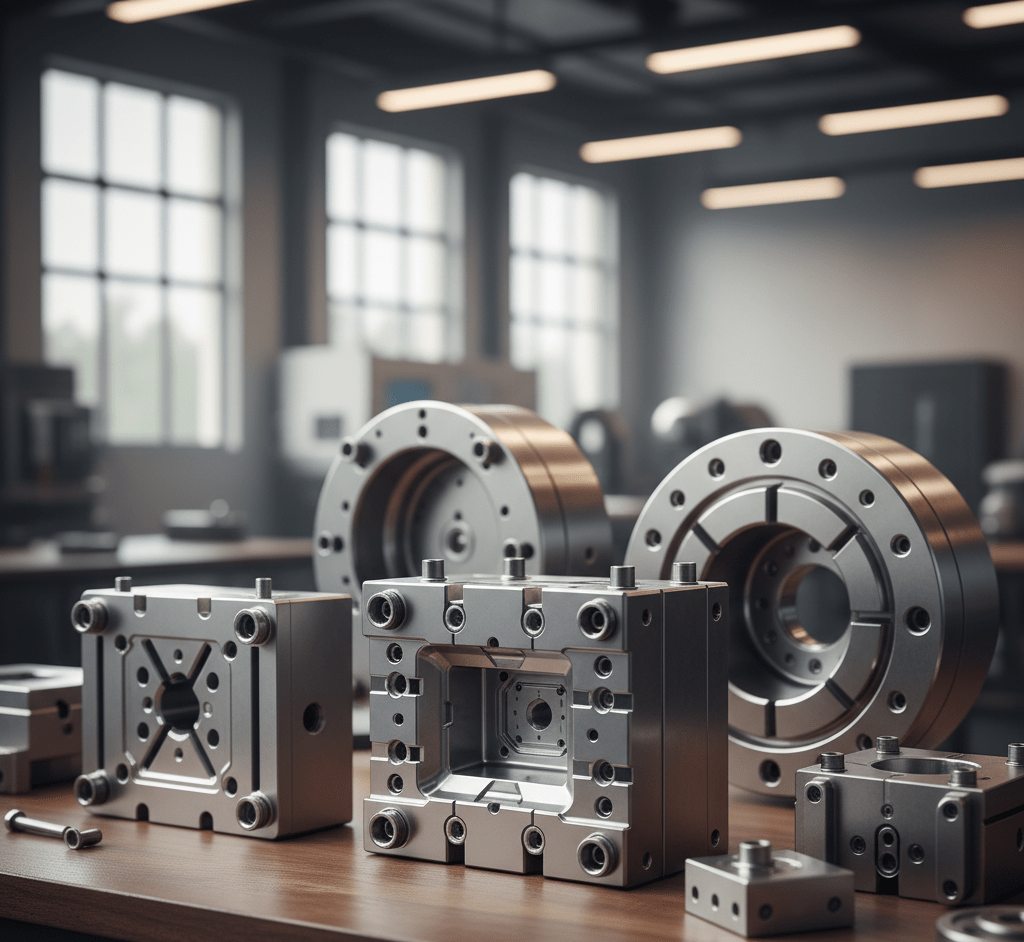

We are specialists in the manufacture of molds for the Plastic Injection industry, metal injection, flexible extrusion, rigid extrusion. Thanks to the experience of manufacturing processes and our human talent. We guarantee our clients the best products with conditions and parameters initially agreed.

Our mold manufacturing processes start from the conception of our clients’ product idea, which we put into format (CAD), where the parameters, conditions, tolerances, among others, are attached. If in any case our clients have doubts or concerns regarding the functionality or final aspect of the components, we offer our line 3D prototyping , later To this, we develop the respective adjustments or increases in the designs in order to mitigate the normal conditions of the material, such as (contraction, deformation, pigmentation, among others), in order to guarantee your products as you initially thought them.

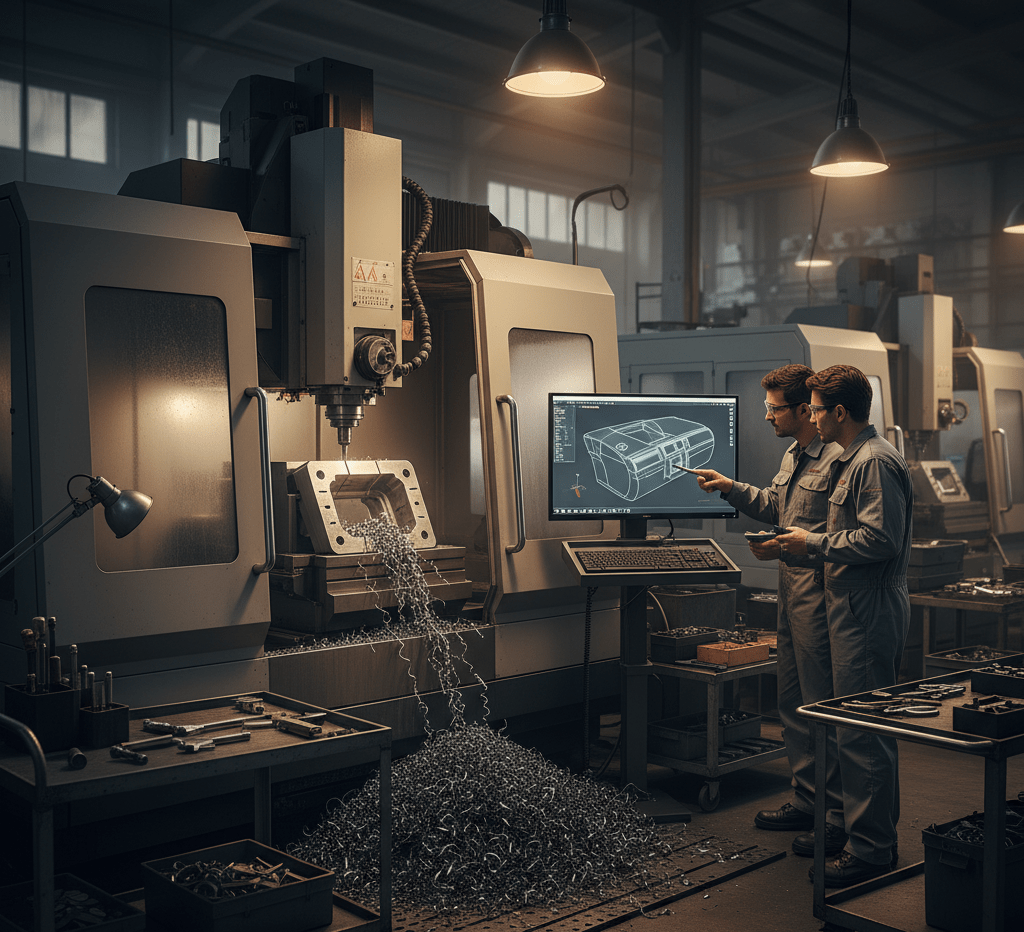

Each stage of the mold manufacturing process is carried out with strict attention to detail, using advanced machining equipment and high-quality materials to ensure durability and precision. Our multidisciplinary team of engineers and technicians supervises every operation — from CNC milling and polishing to assembly and validation — ensuring that every mold meets the highest industry standards. This comprehensive approach allows us to deliver reliable molds capable of maintaining consistency across large production volumes, while reducing waste and optimizing cycle times.

Stages in the Manufacturing of Molds

The manufacturing of molds typically follows several stages to guarantee dimensional precision and durability:

-

Conceptual Design: Engineers create a 3D digital model of the mold, specifying cavity geometry, gating systems, and thermal channels.

-

Simulation and Testing: Software analysis predicts how materials will behave during injection, compression, or casting.

-

Machining: CNC milling, EDM (Electrical Discharge Machining), and surface grinding create the intricate cavities and cores.

-

Assembly and Finishing: Mold parts are fitted, polished, and assembled for final testing.

-

Validation: The mold undergoes production trials to verify functionality, dimensional accuracy, and surface quality.

This step-by-step precision ensures that molds perform flawlessly across repeated cycles, even under high temperature and pressure.

Material Selection and Treatments

Choosing the right material is essential for achieving high-quality Manufacturing of Molds. In the Manufacturing of Molds, tool steels such as P20, H13, and 420 stainless steel are frequently selected because they provide exceptional hardness, wear resistance, and thermal conductivity. These materials ensure that each mold maintains structural integrity under demanding production conditions.

For large-scale Manufacturing of Molds, additional surface treatments such as nitriding, chrome plating, or polishing are applied to enhance performance, reduce friction, and prevent corrosion over time.

Furthermore, precise heat treatments are incorporated into the Manufacturing of Molds process to increase dimensional stability, minimize deformation, and extend the operational lifespan of every mold. This meticulous control guarantees consistent quality and durability across continuous production cycles.

Technological Advances in Mold Fabrication

Innovation plays a decisive role in the manufacturing of molds. Today, technologies such as additive manufacturing (3D printing) are used to create complex cooling systems or rapid prototypes. CNC automation and robotic machining cells enable continuous, high-precision operations.

In addition, simulation software and digital twins allow engineers to detect potential defects like air traps or warpage before a mold is physically produced. These tools reduce costs, optimize design time, and improve final product quality — aligning with Industry 4.0 principles.

Types of Molds and Their Industrial Applications

The manufacturing of molds covers multiple applications across different industries:

-

Injection Molds: For plastic and Zamak parts with fine details and tight tolerances.

-

Compression Molds: Used in rubber and elastomer production for seals, gaskets, and technical parts.

-

Extrusion Dies: Designed to create continuous plastic or aluminum profiles.

-

Casting Molds: For metal parts that require high dimensional accuracy and repeatability.

Each mold type requires specific design strategies to ensure proper filling, cooling, and release, depending on the material and production scale.

Quality Control and Maintenance

Every stage of the mold manufacturing process involves rigorous inspection. Dimensional checks, polishing, and cavity alignment ensure accuracy before full-scale production. Once in use, molds require preventive maintenance — cleaning, lubrication, and periodic verification — to extend their life cycle and maintain product consistency.

This continuous quality management is what allows molds to operate efficiently and maintain productivity across thousands of production cycles.

Comprehensive Manufacturing of Molds for Multiple Industrial Processes

Sumiparts SAS is a specialist in the manufacture of molds for the sector of:

- Plastic Injection

- Aluminum Injection

- Vulcanization

- Plastic extrusion

- Die-Cut

- Polyurethane casting

- thermoformed

If you want to know more about the Design and Manufacturing of Molds, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.