Overview of Tube and Rod Bending

Tube and rod bending is a specialized metal forming process that reshapes cylindrical stock into curves, angles, and complex geometries. Unlike flat sheet bending, cylindrical materials require precise control to maintain diameter, wall thickness, and structural integrity throughout the bend.

Industries such as automotive, aerospace, construction, furniture, and piping systems rely on this technique for components that must fit precisely in assemblies. Controlled bending reduces the need for welding or additional fabrication, resulting in parts that are accurate, strong, and visually appealing.

Methods and Technique

Different bending methods allow manufacturers to meet specific design and material requirements:

-

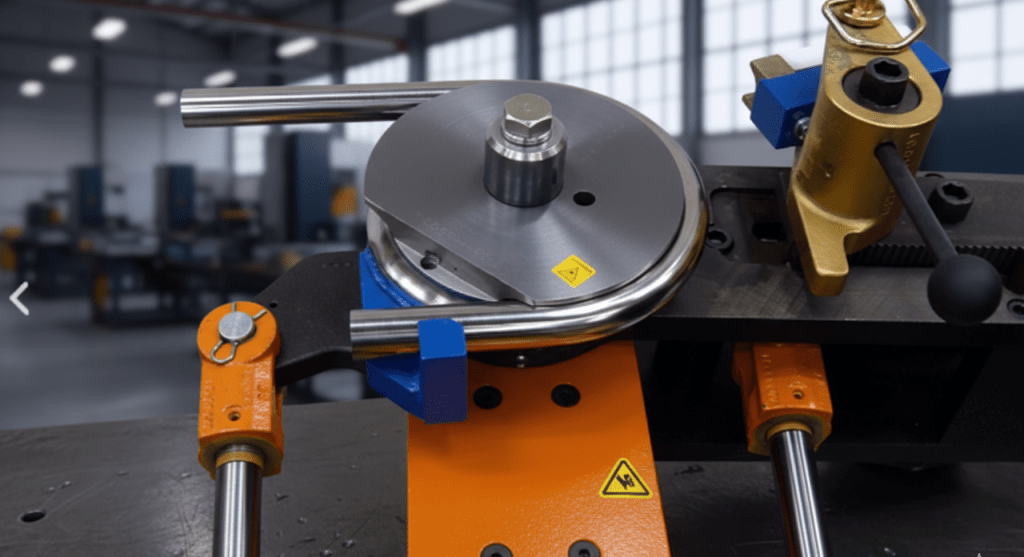

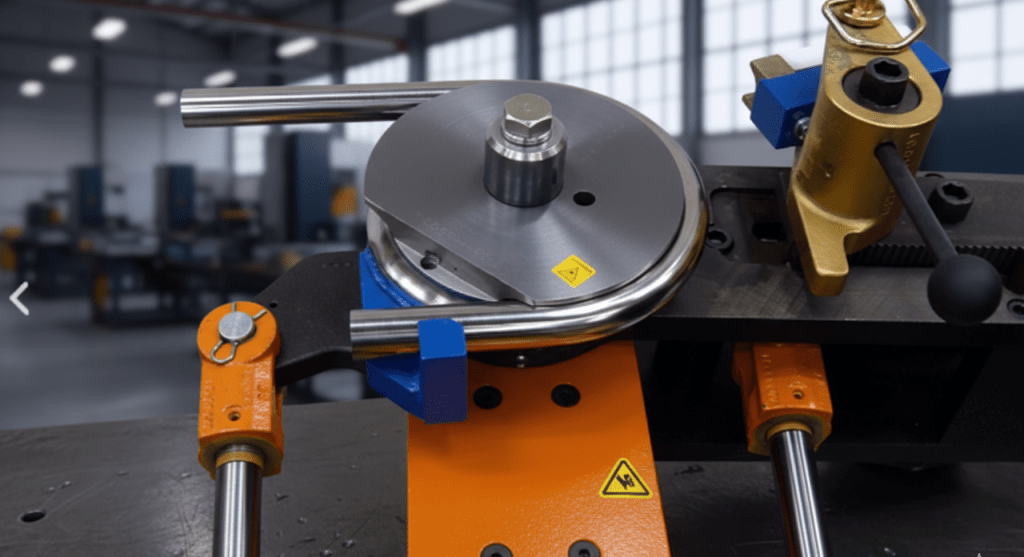

Rotary Draw Bending: The tube is drawn around a rotating die with a supporting mandrel, ensuring tight, uniform bends without flattening.

-

Compression Bending: The tube is held steady while a roller or die presses it into shape, suitable for larger radii.

-

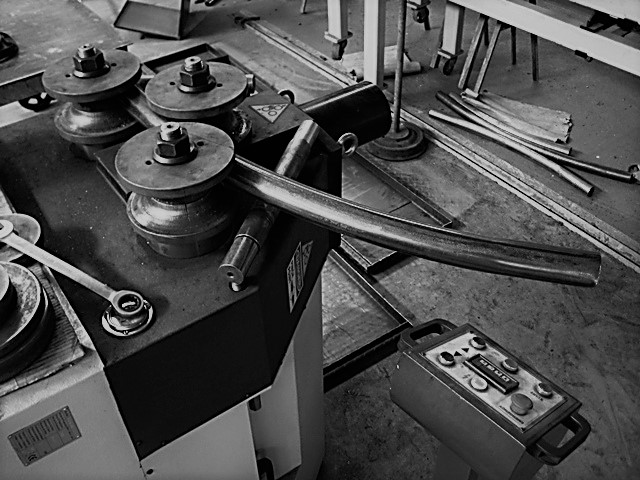

Roll Bending: Sequential rollers gradually curve the tube or rod, ideal for gentle, wide-radius bends.

-

Mandrel-Assisted Bending: A flexible internal mandrel prevents wrinkles or collapse in tight-radius bends.

-

Push or Ram Bending: Simplified technique for lightweight tubes or rods, producing smooth curves in fewer steps.

Modern CNC-controlled machines can automate these techniques, allowing consistent, repeatable bends in high-volume or intricate designs.

Material Selection and Preparation

Successful tube and rod bending requires a thorough understanding of material properties and process parameters. In this type of bending operation, the mechanical behavior of each metal directly influences the accuracy and quality of the final shape.

Metals commonly used in tube and rod bending include steel, stainless steel, aluminum, copper, brass, and titanium, each offering different levels of ductility and strength. Wall thickness plays a crucial role, as it affects both the minimum bending radius and the tooling setup needed to prevent wrinkles or deformation.

The surface finish of the material is another critical factor. Pre-coated or heat-treated surfaces may require specialized lubrication systems or protective pads to avoid scratches during bending. Factors such as tube diameter, alloy composition, and the desired bend radius determine the selection of the most suitable tooling and method — whether rotary draw, compression, or roll bending.

Before any tube and rod bending process begins, careful preparation is essential. This includes inspecting raw stock for surface defects, cleaning to remove debris or contaminants, and calculating accurate bend allowances to compensate for spring-back. These pre-bending steps ensure dimensional precision and extend the life of both the tooling and the finished components.

Preparation and Best Practices

Achieving high-quality results in tube and rod bending requires both technical precision and careful process planning. Each step — from setup to inspection — plays a key role in ensuring that the final components meet structural and aesthetic standards.

-

Align the material correctly:

Tubes or rods must be positioned accurately within the bending machine to maintain symmetry and avoid unwanted deformation. Even small misalignments can lead to inconsistent radii or material stress. -

Use proper tooling and supports:

Incorporate mandrels, formers, or internal supports when working with tight radii or thin-walled sections. These tools help maintain the internal diameter and prevent wrinkling or flattening during the bend. -

Apply suitable lubrication:

Quality lubricants reduce friction and protect the surface finish. This not only prevents scratches but also minimizes internal stress, ensuring smoother and more consistent bends. -

Plan the bending sequence:

Efficient sequence planning avoids collisions between parts and tooling, especially when working with complex multi-bend geometries. It also helps distribute forces evenly, minimizing the risk of overstressing the material. -

Inspect and verify results:

After bending, all components should be checked against design specifications for dimensional tolerances, wall thinning, and surface quality. Non-destructive testing methods can be used for critical parts.

When these practices are applied consistently, manufacturers can minimize waste, reduce rework, and achieve higher production efficiency. Combined with advanced CNC control and quality materials, these techniques ensure that tube and rod bending delivers precise, reliable, and visually refined results — essential for industries such as automotive, aerospace, and construction.

Rod bending when machining

Another type of bending that is also used for precision machining is rod bending .

During the bending process , in which the metal is compressed inside, the base material is placed in the machine and driven until the desired dimension is achieved. rod bending uses specialized machines , such as bending rollers .

If you want to know more about the Tube and rod Bending, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.