The bending and curving of sheet metal is an operation that consists of getting a piece with generatrices and rectilinear edges, exerting a force of a certain intensity, which causes a permanent deformation of the sheet metal according to the wanted curvature. Normally for this process we will use a press with a matrix .

When we make a bent we can see that the outer part of the sheet and the inner part expand or compress , this is because the strength limit of the materials is not the same under traction than under compression, as materials have a higher elastic limit in compression, a greater plastic deformation will occur on the outside part of the material .

This phenomenon causes that the neutral axis is not equidistant from the two surfaces, therefore, it is closer to the internal surface than to the external one, since the external part yields earlier, because its elastic limit is less, that also may depend on the thickness of the piece that we are bending.

Factors involved in sheet metal bending

- Elasticity of the material : It is the factor that influences the recovery of the material , we must accentuate the bending angles. Therefore, if we want to perform a bend, we will have to do it at a higher value than the required to compensate elastic recovery .

- Radius of curvature : Influences the thickness variation in a decisive way . Also in the appearance of cracks and subsequent breaks . Bends without an internal radius should always be avoided.

- Direction of the fibers : It will depend on the previous lamination that has been subjected. Therefore, the direction where the fibers are will be of great importance because if we make a bend against the direction of the fibers , the test piece will have worse performance, worse quality and worse durability than if it had been done in favor of the fibers.

When performing a bending operation, what we do is to make a small deformation of the material. A slight molecular shift in that part when bending is done.

Phenomena that occur in sheet metal bending

When making the bending and curving of sheet metal, what we are doing is compressing its inner part and stretching its outer part . Consequently, the fibers of the material suffer in the bending zone. The smaller the radius to be achieved, the more intense the requests will be.

Smallest inside radius that can be achieved for a given material.

When the sheet is compressed or stretched on both sides, the particles change their position. There is a neutral zone where the stresses are zero and there is no deformation. The decentration of the neutral axis depends to a large extent on the thickness of the piece and the bending radius.

The designation of the neutral zone will be of great interest , since it will be essential to calculate the length of the bent profiles. It tends to move into the curvature when the ratio is smaller.

Development of a bent part

To calculate the development , the position of the neutral line is determined. So the development of the piece will be the line of the neutral fiber.

The neutral fiber designates the area of a bent element. That does not undergo any deformation , its fibers will not be modified as a result of traction or compression.

The neutral fiber is not always in the center of the sheet. This takes a different position depending on the thickness of the material and the radius of a particular bending. The calculation of the fiber is a basic element for the development at the time of bending the elements.

To calculate the fiber of an approximated shape , it is necessary to start from a flat piece with the appropriate profile. The aforementioned development would be calculated according to the average thickness line of the sheet if the bend retained thickness.

ri=Intern ratio

Elastic recovery after bending and sheet metal bending

Called return factor or elastic recovery , the recovery of the sheet as soon as the action of the punch on it ceases, it is due to the deforming action to which the sheet has been subjected, this < strong> tends to revert to its primitive form . This reaction is due to the property of bodies to be elastic.

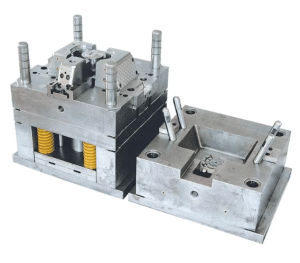

When building a bending mold the return factor must be taken into account. With the intention of constructing the punches or matrices with the angles and modified ratio, so that the manufactured part is the same to measurements of the plane.

Elastic recovery varies based on the following factors:

- Type of material : Depending on the hardness of the material, the deformations may vary.

Material thickness : The greater the thickness, the less elastic recovery . - Radius of curvature : A greater radius, greater elastic recovery .

- Bending angle : A greater radius of curvature, greater recovery elastic. On the contrary, the smaller radius of curvature, smaller elastic recovery .

Bending methods

Central action : it is a bending used to bend large profiles

Side action: perfect bends are obtained, due to the small lever arm in which the punch acts. it is the most used system for bending small pieces.

Front action: used mainly in profiles for closed or curved bends

Examples of different types of bends for machining parts.