What Is Rubber Extrusion?

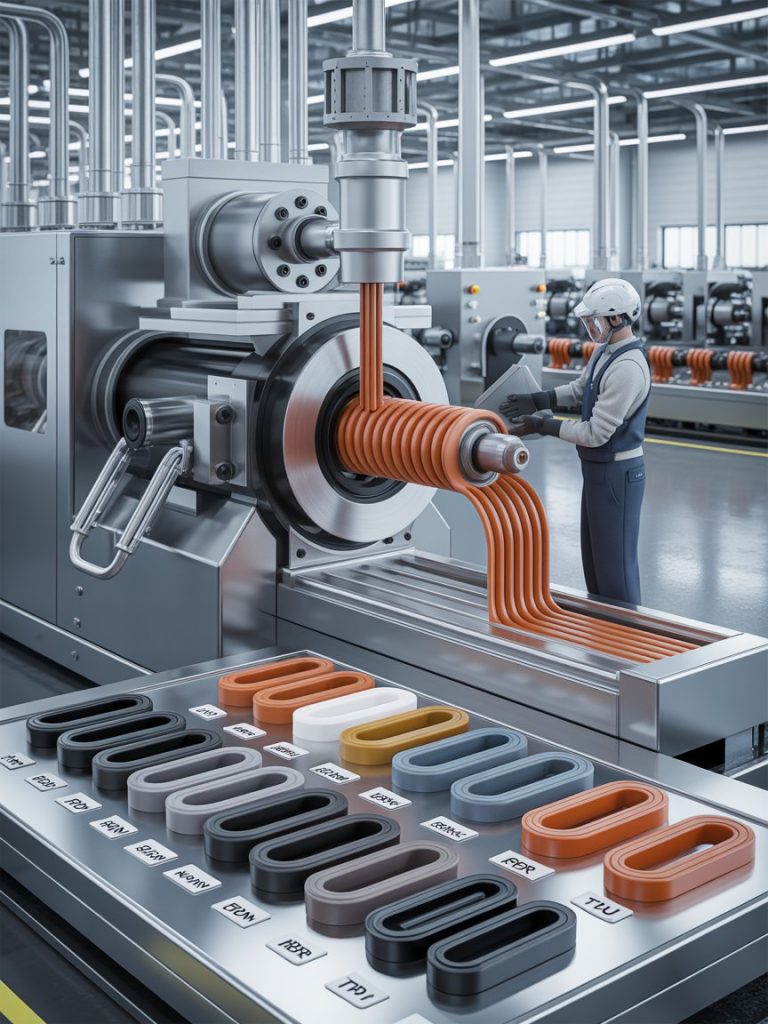

Rubber Extrusion is a manufacturing process that transforms raw rubber compounds into continuous shapes with consistent cross-sections. Using a specialized extrusion machine, rubber is forced through a die, forming profiles such as seals, gaskets, tubing, or custom shapes.

This Rubber Extrusion technique is widely used in automotive, construction, industrial, and consumer products, offering flexibility in design, material choice, and production scale. It ensures uniformity, strength, and functional performance, making Rubber Extrusion an essential method for producing high-quality rubber components.

Types of Rubber Extrusion According to Vulcanization Processes

Rubber Extrusion can be classified based on the vulcanization process used to cure the material. Understanding these types ensures optimal performance, consistency, and durability in the final products.

Continuous (Non-stop) Vulcanization Extrusion: In this process, the extruded rubber passes through a curing or vulcanization tunnel, where the temperature is carefully controlled to achieve the desired level of vulcanization. This method allows for highly uniform rubber extrusion over long continuous runs, ideal for producing consistent profiles with minimal defects.

Off-line Vulcanization Extrusion: Here, the rubber is first extruded through the die and then exposed to high-pressure steam to reach the required vulcanization temperature. This approach provides flexibility for smaller production runs or specialized shapes, allowing manufacturers to produce customized rubber extrusion profiles efficiently.

Both methods are widely used in the Rubber Extrusion industry, depending on production volume, material type, and technical requirements.

Advantages of the Process

The Rubber Extrusion process offers numerous benefits for industrial and commercial applications:

Wide variety of shapes: Rubber extrusion allows complex cross-sections that can be tailored to specific technical specifications.

Economical process: Efficient material usage and reduced waste make it a cost-effective manufacturing method.

Flexible and lightweight products: Rubber extrusion produces parts that maintain flexibility without adding unnecessary weight.

High efficiency: Continuous or off-line extrusion enables fast production and scalability for small or large orders.

Thanks to these advantages, is widely preferred for producing seals, gaskets, tubing, protective profiles, and other industrial components.

Materials Used

Modern techniques support a wide range of elastomers and compounds, offering versatility in applications. Our factories and suppliers are capable of producing custom rubber parts from virtually any type of rubber, including

EPDM: Excellent weather and ozone resistance, ideal for outdoor seals.

TPU (Thermoplastic Polyurethane): High elasticity and wear resistance.

Foam Rubber: Lightweight, cushioning, and insulating applications.

Neoprene: Chemical and oil-resistant, suitable for industrial components.

Butyl Rubber: Gas impermeability and excellent sealing properties.

Fluoroelastomer / FKM (Viton): High-temperature and chemical resistance.

Nitrile Rubber (NBR): Oil and fuel-resistant for automotive and industrial parts.

Polyisoprene: Natural rubber alternative for flexible components.

PVC: Cost-effective, versatile profiles for various uses.

Silicone (VMQ): Heat-resistant and flexible, suitable for medical and food applications.

This wide material compatibility makes a highly versatile process, capable of meeting diverse industrial requirements and producing profiles that comply with stringent technical standards.

Customization and Technical Capabilities

Our Rubber Extrusion facilities can produce a wide variety of cross-sections, even fully customized shapes and sizes, according to the customer’s specifications. By combining precision dies, advanced extrusion equipment, and material expertise, manufacturers can achieve consistent quality across every batch.

Whether the requirement is high-volume production or specialized custom profiles, Rubber Extrusion allows for reliable, cost-effective, and high-quality results across multiple industries.

Innovations and Trends in Rubber Extrusion

This field is constantly evolving as manufacturers seek higher efficiency, better material performance, and more complex designs. Some of the latest trends and innovations include:

Advanced automation: Modern extrusion lines use robotic handling and automated quality checks to improve precision and reduce human error.

Hybrid extrusion processes: Combining traditional extrusion with post-extrusion curing, co-extrusion, or multi-material extrusion enables more sophisticated profiles in a single process.

Eco-friendly materials: Sustainable and recyclable rubber compounds are increasingly used, making Rubber Extrusion both environmentally responsible and cost-effective.

Custom surface textures: Some extruded profiles now include textured or patterned surfaces directly from the die, eliminating additional finishing steps.

High-performance elastomers: New synthetic rubbers with superior temperature, chemical, and wear resistance expand the applications of Rubber Extrusion in demanding industries like aerospace, medical, and automotive.

These advancements ensure remains not only a reliable production method but also a platform for innovation, enabling manufacturers to meet complex design challenges and stringent industry standards.

If you want to know more about the Rubber Extrusion, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.