How CNC Machining is Transforming Modern Manufacturing

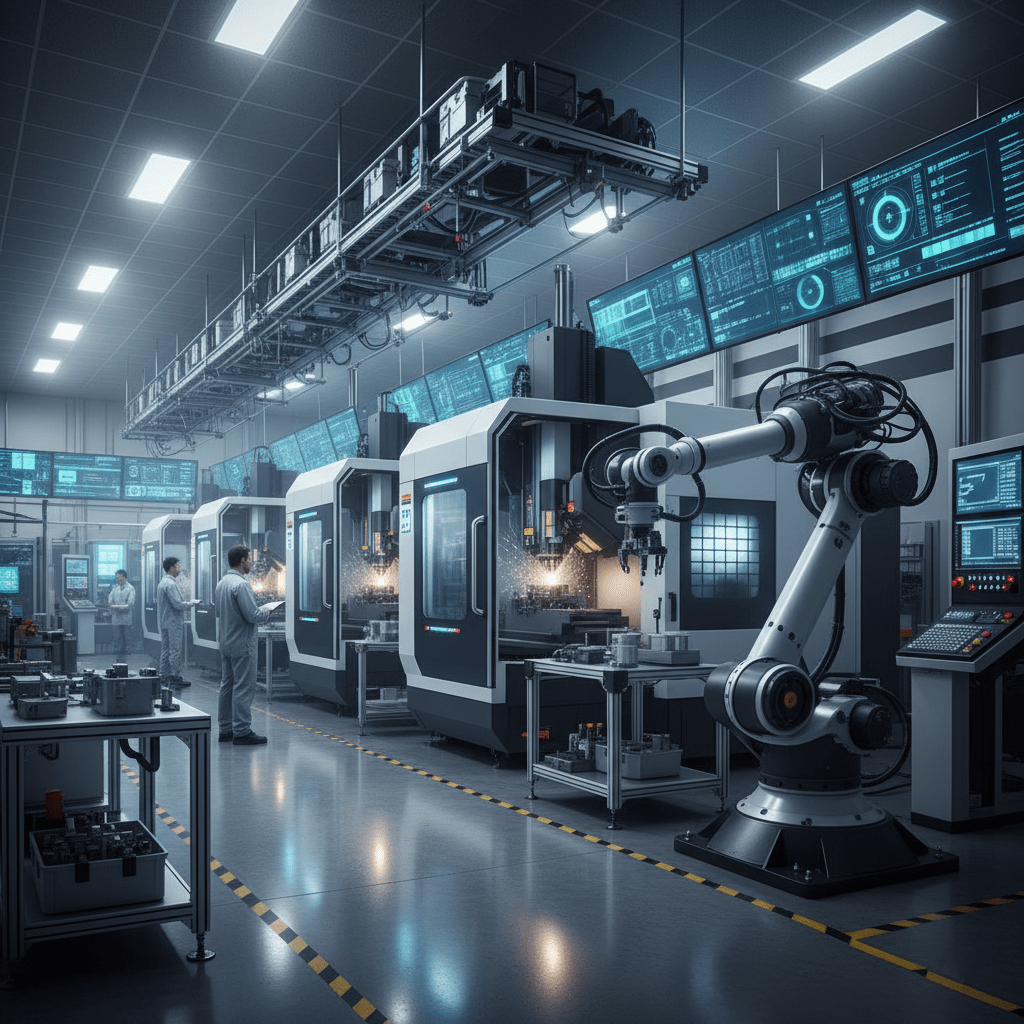

CNC Machining — or Computer Numerical Control Machining — is one of the most transformative technologies driving the Fourth Industrial Revolution. This advanced process merges automation, digital precision, and mechanical control to produce high-quality components for the automotive, aerospace, construction, and industrial manufacturing sectors.

At Sumiparts SAS, we specialize in CNC Machining services that combine technological innovation with exceptional craftsmanship. Our modern machining centers and specialized engineering team allow us to create complex geometries with outstanding accuracy, repeatability, and efficiency. Each process is digitally programmed to ensure consistency and precision, meeting the strictest international quality standards.

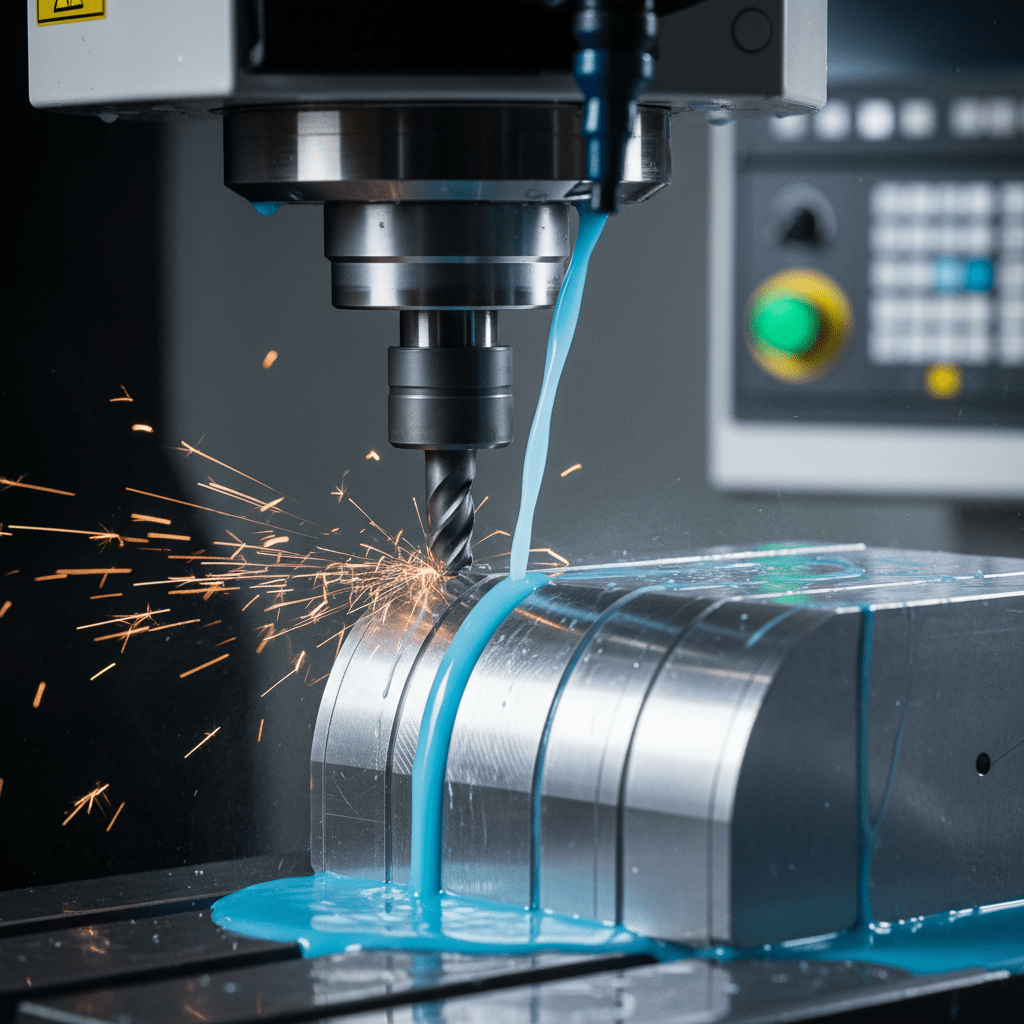

The CNC Machining process starts with a digital design developed through CAD software. These models are then transformed into exact machining instructions that control cutting tools along pre-defined axes. This computer-controlled precision enables the shaping of metals, plastics, and specialized materials into components with minimal error margins and flawless surface finishes.

One of the greatest strengths of CNC Machining is its integration with the digital technologies that define Industry 4.0. Automation, data exchange, and real-time control allow faster production cycles, predictive maintenance, and reduced material waste. The synergy between intelligent systems and CNC equipment ensures higher productivity, customization flexibility, and operational sustainability.

In the context of the Fourth Industrial Revolution, CNC Machining serves as the bridge between digital design and physical manufacturing. The use of sensors, interconnected machines, and continuous data analysis allows for ongoing process optimization. This digital connection results in greater precision, lower production costs, and improved energy efficiency — essential factors for sustainable industrial growth.

At Sumiparts SAS, our CNC Machining services are tailored to meet the needs of each client. From prototyping to full-scale production, we guarantee precision tolerances, high mechanical performance, and superior finishing. Our machining capabilities include materials such as stainless steel, aluminum, brass, engineering plastics, and other industrial alloys.

We also integrate CNC Machining with complementary services such as electropolishing, injection molding, and surface finishing — offering complete manufacturing solutions in one place. Each component undergoes strict inspection to ensure durability, resistance, and long-term performance in the most demanding environments.

The Fourth Industrial Revolution has transformed manufacturing into a smart, connected, and data-driven ecosystem. CNC Machining is at the core of this transformation — merging automation, precision, and innovation to redefine the way products are designed and produced.

At Sumiparts SAS, we are proud to lead this evolution. Our advanced CNC Machining services empower innovation, enhance performance, and ensure excellence in every part we manufacture — turning digital ideas into tangible, high-precision results.

The Future of CNC Machining and Industrial Technologies

The evolution of CNC machining continues to accelerate with the integration of emerging technologies that are reshaping industrial production worldwide. The combination of artificial intelligence (AI), machine learning, and data analytics is allowing machines to learn from every operation, optimizing cutting speeds, reducing tool wear, and predicting maintenance needs before downtime occurs. This transformation moves the industry toward a model of smart, autonomous manufacturing — where decisions are made in real time based on data, not just operator experience.

Another major influence is the advancement of additive manufacturing (3D printing), which complements CNC machining by enabling the production of complex geometries, lightweight components, and rapid prototyping. Hybrid systems that combine both subtractive and additive processes are becoming increasingly common, maximizing efficiency and material use.

Internet of Things (IoT) connectivity is also playing a crucial role, linking CNC machines, sensors, and production systems to centralized control platforms. This interconnectivity provides continuous monitoring, ensuring consistency, traceability, and improved energy management — key factors in modern Industry 4.0 environments.

At Sumiparts SAS, we closely follow these technological trends to stay ahead of the curve. Our goal is to integrate smarter control systems, advanced simulation software, and sustainable production methods to meet the growing demands of the automotive, construction, and industrial sectors. By adopting these innovations, we continue to deliver precision, quality, and efficiency in every component we produce.

The future of CNC machining is one of adaptability, intelligence, and precision — and at Sumiparts SAS, we are ready to lead this new era of industrial transformation.