Key Features and Advantages of UHMW Plastic

UHMW (Ultra High Molecular Weight Polyethylene) is a high-density, high-performance engineering plastic recognized for its outstanding abrasion resistance, exceptional impact strength, and superior durability, even under cryogenic conditions. Its low coefficient of friction, self-lubricating properties, and excellent sliding performance make it an ideal material for heavy-duty industrial components, precision machinery, and equipment exposed to harsh environments. UHMW provides long-lasting performance in applications requiring continuous wear resistance, low maintenance, and high reliability.

CNC MACHINING IN UHMW: For cylindrical parts, CNC turning is the preferred method for producing bushings, rollers, spacers, and shafts. With our state-of-the-art CNC lathes, we achieve high precision, superior surface finishes, and repeatable accuracy. This process allows for cost-effective production of large quantities without compromising the mechanical properties or performance of UHMW components.

CNC TURNING IN UHMW: For cylindrical parts, CNC turning is the preferred method for producing bushings, rollers, spacers, and shafts. With our state-of-the-art CNC lathes, we achieve high precision, superior surface finishes, and repeatable accuracy. This process allows for cost-effective production of large quantities without compromising the mechanical properties or performance of UHMW components.

Our advanced CNC milling equipment enables the production of custom, complex, and high-precision parts. From special fabrications to inline production, we deliver components that meet strict industrial standards. Milling is perfect for slide bearings, conveyor guides, protective panels, and structural components, ensuring durability, low friction, and minimal wear over time.

At SUMIPARTS SAS, every stage of UHMW processing is carefully monitored, combining engineering expertise, modern machinery, and rigorous quality control. This approach guarantees that components not only meet precise specifications but also deliver long-term performance, reliability, and efficiency in industrial applications ranging from automotive and construction to food processing and heavy machinery.

Engineering Plastics – Applications and Advantages

Engineering plastics have become indispensable materials across multiple industries, including automotive, industrial machinery, construction, and heavy equipment manufacturing. Their unique combination of mechanical strength, chemical resistance, dimensional stability, and wear resistance allows engineers to design components that maintain high performance under demanding conditions. Unlike conventional plastics, engineering plastics are specifically formulated to endure environments with high friction, repeated wear, humidity, and mechanical stress, making them ideal for applications where durability, precision, and reliability are critical.

In the automotive sector, engineering plastics are widely used for the production of gears, bearings, bushings, pulleys, and sliding components. These parts are often exposed to continuous mechanical loads, high temperatures, and contact with oils or lubricants, so material selection is critical. Components made from high-performance plastics, such as Acetal (POM), UHMW, ABS, and Polyamide (PA), ensure long-term stability and reduced maintenance costs, while allowing manufacturers to lightweight vehicles, improving fuel efficiency and overall vehicle performance.

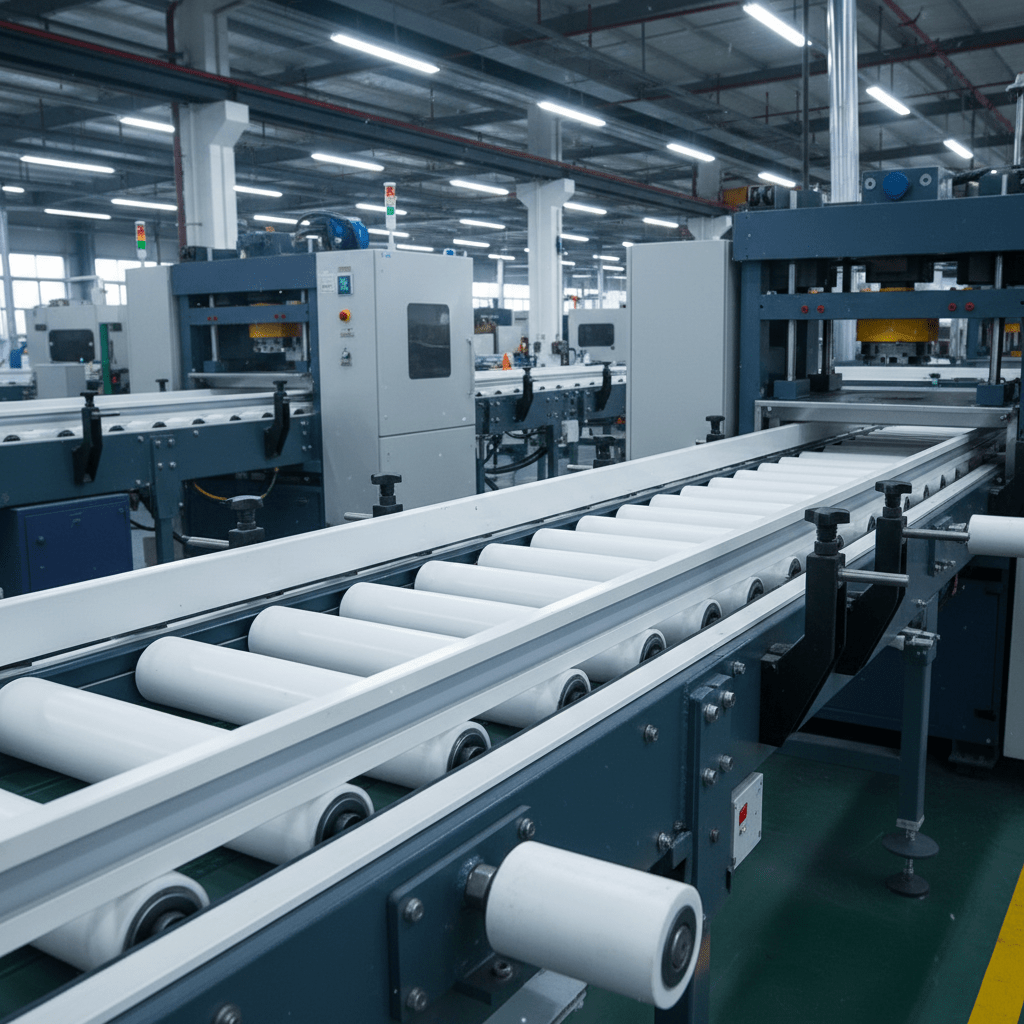

The industrial and machinery sector also relies heavily on engineering plastics. Conveyor systems, rollers, guide rails, chutes, protective panels, and high-precision mechanical components are often manufactured using high-density and wear-resistant plastics. These materials reduce friction and abrasion, extending the service life of machinery and decreasing downtime. Additionally, engineering plastics can withstand exposure to chemicals, oils, and extreme temperatures, making them suitable for chemical plants, food processing lines, and heavy industrial equipment.

In the construction industry, engineering plastics are increasingly used for flooring systems, expansion joints, protective covers, anti-slip pads, and vibration dampers. Components exposed to dynamic loads, moisture, and environmental fluctuations benefit from plastics that combine strength, flexibility, and dimensional stability. Their use reduces maintenance costs and ensures the structural integrity of construction assemblies, particularly in bridges, industrial platforms, and public infrastructure.

At SUMIPARTS SAS, our experienced engineering and production teams provide customized solutions for every application. We combine modern CNC machining, precision molding, extrusion, and finishing processes to deliver parts tailored to each customer’s requirements. Our CAD/CAM design department works closely with clients to ensure the best fit, functionality, and aesthetic quality for each component.

Our capabilities cover high-volume production, tight tolerance machining, and complex geometries, allowing the creation of components that would be difficult or impossible to achieve with traditional materials. This includes custom bushings, gears, sliding pads, protective components, conveyor guides, and high-performance industrial parts. By leveraging advanced engineering plastics, SUMIPARTS SAS ensures that each product meets international standards for mechanical performance, chemical resistance, and longevity.

Furthermore, our approach emphasizes continuous improvement, quality assurance, and technological innovation. We constantly invest in modern equipment, staff training, and process optimization to guarantee that each component maintains precision, durability, and reliability. Working with engineering plastics also allows clients to optimize production processes, reduce downtime, and achieve cost-effective, high-performance solutions across automotive, industrial, and construction sectors.

The use of engineering plastics not only enhances product longevity and performance but also supports sustainability initiatives, as many of these materials can be recycled, reused, or replaced in environmentally friendly ways. This aligns with the growing demand for eco-conscious manufacturing without compromising on industrial standards or operational efficiency.

In conclusion, engineering plastics play a fundamental role in modern manufacturing, providing versatile solutions for a wide range of industrial, automotive, and construction applications. At SUMIPARTS SAS, our combination of experience, technical expertise, and advanced manufacturing processes ensures that every component performs optimally, is delivered on time, and meets the specific needs of each customer.

With a focus on innovation, precision, and quality, SUMIPARTS SAS continues to be a trusted partner for companies seeking high-performance, durable, and reliable components made from engineering plastics.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 318 728 7721, or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.