Silicone Rubber: Industrial Performance and Transformation Processes

Silicone Rubber is a high-performance elastomer obtained from the polymerization of silicone, carbon, hydrogen, and oxygen. It is available on the market in multiple formulations that vary in hardness, flexibility, and resistance, depending on its intended use. This material stands out for its exceptional chemical stability and its ability to maintain physical and mechanical properties in environments with extreme temperatures — from cryogenic levels to over 250°C — without suffering degradation or deformation.

Due to these unique characteristics, Silicone Rubber has become a key material in engineering and industrial manufacturing. It offers durability, flexibility, and resistance to weathering, ozone, and ultraviolet light, making it suitable for both indoor and outdoor applications where long-term reliability is essential.

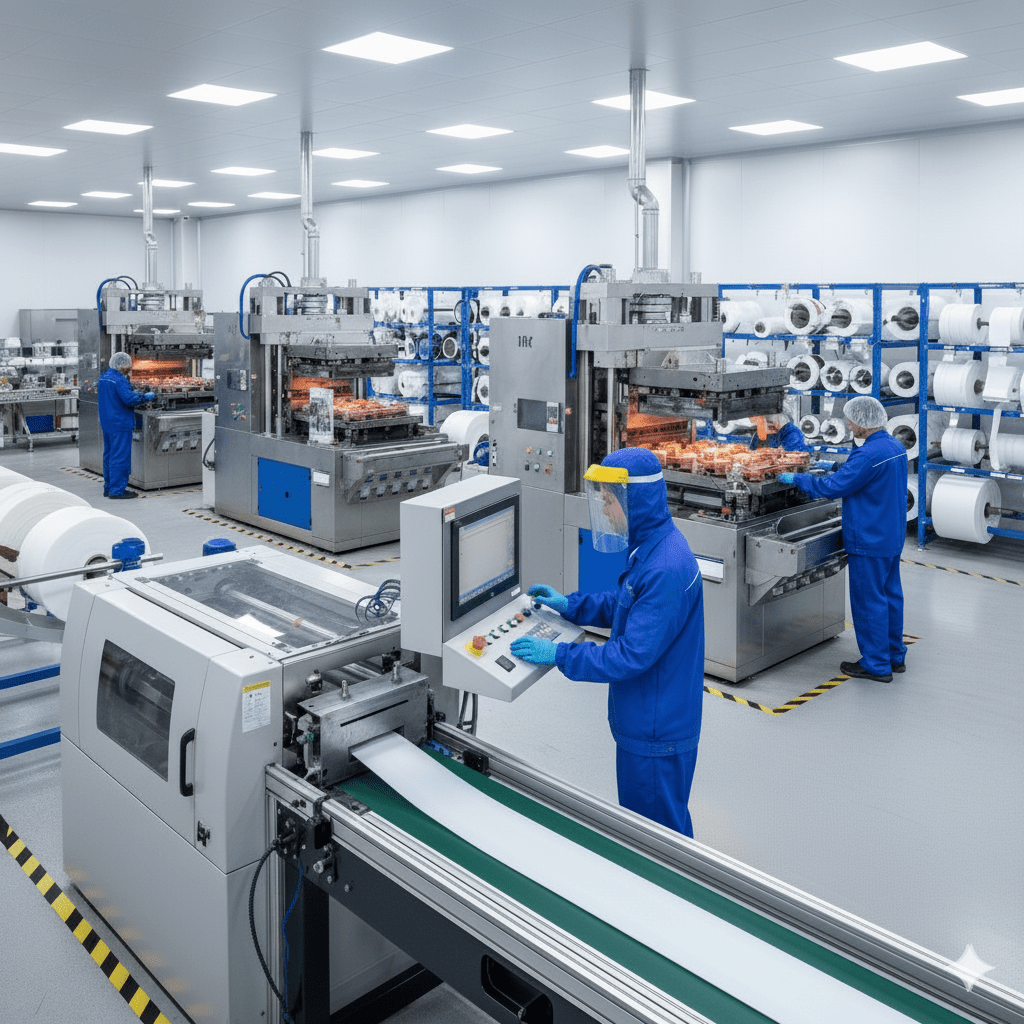

At Sumiparts SAS, we specialize in the transformation and manufacturing of silicone-based components through advanced Vulcanizing and Extrusion processes. Our production capabilities allow us to design and fabricate a wide range of customized pieces that meet the highest quality standards and performance expectations.

Quality Control and Technical Support in Silicone Rubber Manufacturing

At Sumiparts SAS, quality is at the core of every Silicone Rubber product we manufacture. Each part undergoes a rigorous inspection process — from raw material selection to final testing — ensuring compliance with international standards for mechanical strength, elasticity, and dimensional stability.

Our in-house laboratory and precision measurement equipment allow us to validate the thermal resistance, compression set, and chemical durability of every batch. This commitment guarantees consistency, reliability, and superior performance across all production runs.

Beyond manufacturing, our engineering team provides technical support and co-design services, helping clients select the right silicone formulation and process for their specific application. Whether it’s a prototype or a high-volume production, we collaborate closely with our customers to achieve optimal results and cost-efficient solutions.

With this level of process control and technical expertise, Sumiparts SAS stands out as a trusted partner in Silicone Rubber manufacturing, ensuring that every project meets the highest expectations of quality and innovation.

Applications and Industrial Advantages of Silicone Rubber

Silicone Rubber is a versatile material widely used across multiple industries, including automotive, industrial manufacturing, construction, food processing, and household goods. Thanks to its unique combination of flexibility, chemical resistance, and thermal stability, Silicone Rubber is ideal for producing seals, gaskets, hoses, protective coatings, and insulation components that perform reliably under demanding conditions.

In the automotive sector, Silicone Rubber is essential for the production of gaskets, vibration dampers, and wiring insulation, ensuring durability and resistance to heat and oil. In industrial applications, it is used for sealing systems, flexible joints, and protective linings exposed to high temperatures or corrosive environments. Within construction, it provides weather-resistant joints, coatings, and sealants that maintain elasticity and waterproofing over time.

Additionally, Silicone Rubber plays a key role in the food and medical industries, where its non-toxic and hygienic properties make it suitable for tubing, molds, and equipment requiring strict safety and sanitation standards.

At Sumiparts SAS, we are at the forefront of Silicone Rubber processing, using state-of-the-art machinery for vulcanizing and extrusion processes. Our advanced technology allows us to maintain consistent quality, precision, and high production volume to meet the needs of every project.

SUMIPARTS SAS has an experienced team of engineers and technicians who combine technical knowledge and manufacturing expertise to deliver customized solutions. Each component is developed under strict quality control systems to ensure that the final product meets international standards and exceeds customer expectations.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click here

, or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.