Key Properties and Advantages of Rigid PVC

Polyvinyl Chloride (PVC) is obtained through the polymerization of the vinyl chloride monomer, resulting in one of the most versatile and widely used thermoplastics in modern industry. Rigid PVC Extrusion stands out for its excellent chemical resistance, mechanical strength, and dimensional stability, making it an ideal material for structural and industrial applications.

This amorphous polymer exhibits outstanding resistance to diluted and concentrated acids, alkalis, and many corrosive agents, ensuring long-term durability even under harsh environmental conditions. Additionally, PVC is a remarkable electrical insulator, absorbing very little moisture, which enhances its performance in electrical and mechanical components.

Rigid PVC also offers excellent fire-retardant properties, as it does not propagate flames, providing a high level of safety in industrial and construction environments. It can be easily welded, glued, and thermoformed, allowing the creation of customized profiles and components with tight tolerances.

Thanks to these unique characteristics, Rigid PVC Extrusion is widely used in the construction, automotive, electrical, and industrial sectors, where reliability, corrosion resistance, and cost-efficiency are essential.

Rigid PVC Injection and Extrusion Expertise

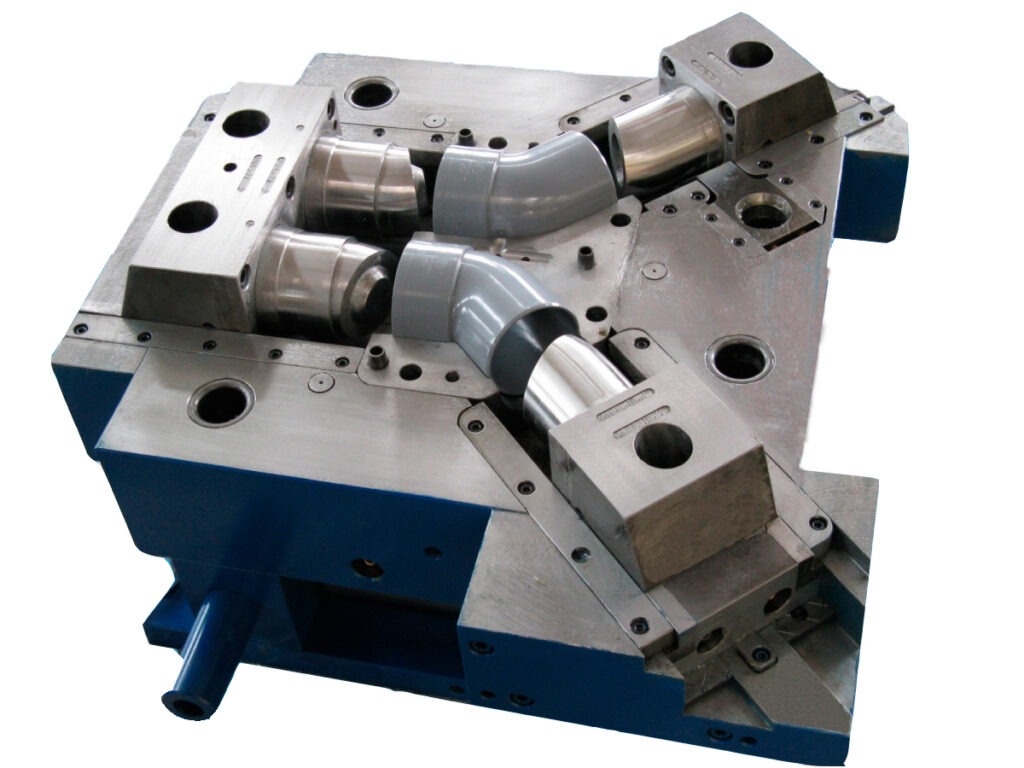

At SUMIPARTS, we provide advanced Rigid PVC Injection and Extrusion processes designed to meet the most demanding industrial standards. Our specialized engineering and production departments work together to design and manufacture precision molds, ensuring consistency and efficiency in every project. With extensive experience in Rigid PVC Extrusion, we are capable of achieving high production volumes while maintaining strict quality control at every stage of manufacturing.

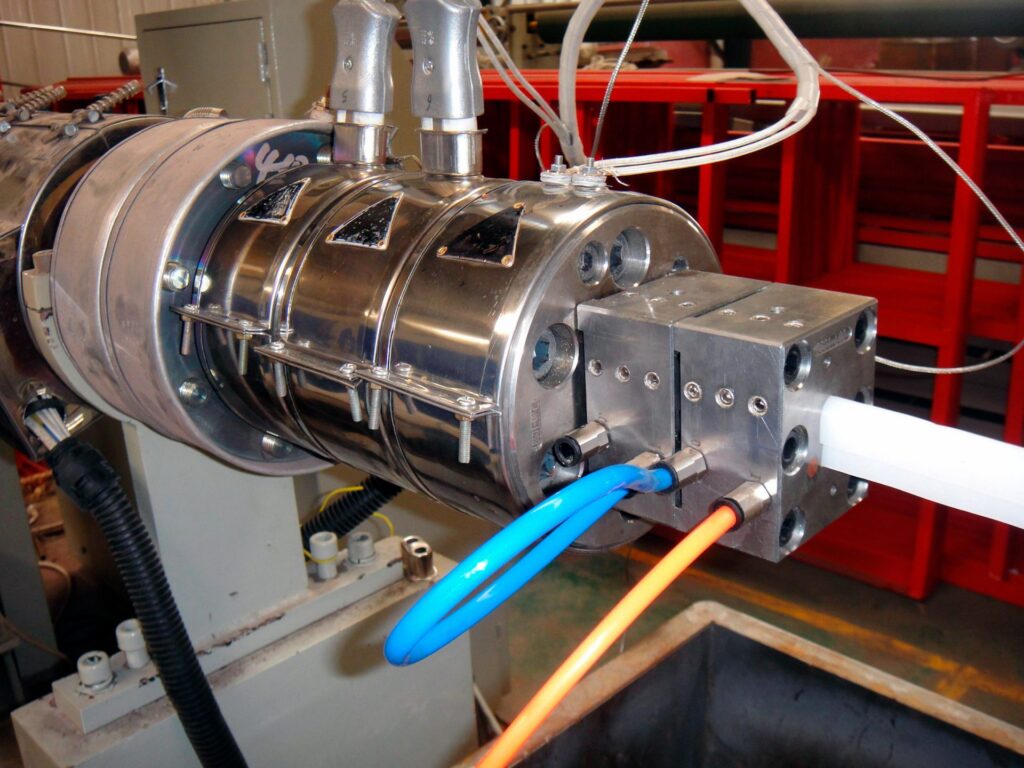

Our production lines are equipped with state-of-the-art extrusion machinery, automated temperature control systems, and dimensional verification tools that guarantee optimal surface finish and mechanical performance. This enables us to create customized profiles, pipes, and components with exceptional precision and repeatability, meeting both structural and functional requirements.

Rigid PVC is one of the most versatile materials in modern industry due to its chemical resistance, rigidity, and electrical insulation properties. Among its most common applications are storage tanks, containers for water and chemical components in industrial plants, sewage treatment systems, and machinery parts. It is also widely used in electroplating systems, industrial piping, and custom components in the automotive sector, where its durability and resistance to corrosion are essential.

At SUMIPARTS, we continuously innovate in Rigid PVC manufacturing techniques, combining engineering expertise with modern equipment to ensure long-lasting and cost-effective solutions. Whether for small-scale prototyping or large-volume production, our focus remains on efficiency, precision, and quality assurance.

Industrial Applications of Rigid PVC

Rigid PVC has become one of the most widely used engineering plastics across multiple industries thanks to its exceptional balance between performance, durability, and cost efficiency. Its adaptability allows it to replace metal, wood, or other polymers in many applications, without compromising structural strength or chemical resistance.

In the industrial sector, Rigid PVC is a preferred material for tanks, ducts, and containment systems designed to store or transport aggressive chemical substances. Its natural resistance to corrosion and acids makes it ideal for manufacturing components used in chemical processing plants, wastewater treatment systems, and electroplating facilities. The material remains dimensionally stable even when exposed to prolonged humidity or fluctuating temperatures, ensuring a long operational life with minimal maintenance.

Another important use is in machinery construction and process equipment. Many manufacturers use Rigid PVC for protective housings, guides, spacers, and machine guards, where impact resistance and insulation properties are required. In automated environments, these parts reduce vibration, minimize friction between moving components, and improve safety conditions for operators.

In the construction sector, Rigid PVC plays a critical role in the production of pipes, profiles, panels, and structural reinforcements. Thanks to its light weight and ease of fabrication, it allows faster installations and reduces transportation costs compared to metal alternatives. Additionally, its resistance to UV rays and outdoor weathering ensures long-term performance, even in harsh environmental conditions.

In electrical and electronic systems, Rigid PVC is used as an insulating and protective material in cable trays, junction boxes, and distribution boards. Its excellent dielectric properties prevent short circuits and ensure safety in industrial environments with high energy demands. The material’s self-extinguishing nature also makes it an excellent option for environments where fire resistance is a critical factor.

In the automotive and transportation industry, Rigid PVC contributes to the manufacturing of trim components, panels, and structural supports that combine lightness with rigidity. It can be easily shaped, welded, or bonded to other materials, which simplifies assembly processes and reduces production costs. Its vibration absorption and low noise emission make it suitable for applications where acoustic comfort is essential.

Beyond these conventional sectors, Rigid PVC is increasingly being used in renewable energy systems — for example, in housings for solar panel inverters or structural supports in photovoltaic installations. Its long life cycle and chemical stability make it a material aligned with modern sustainability and durability standards.

Finally, it is also applied in custom industrial solutions, where companies like SUMIPARTS design and produce parts tailored to the specific requirements of each client. From small precision fittings to large modular structures, the versatility of Rigid PVC allows for a wide range of technical and creative possibilities.

SUMIPARTS SAS has an experienced team of staff, who with their knowledge and skills can provide an excellent service and final product tailored to the needs.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 318 728 7721 WhatsApp click here , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you. we leave you these links that may be of your interest Bronze