Overview of Milling Processes

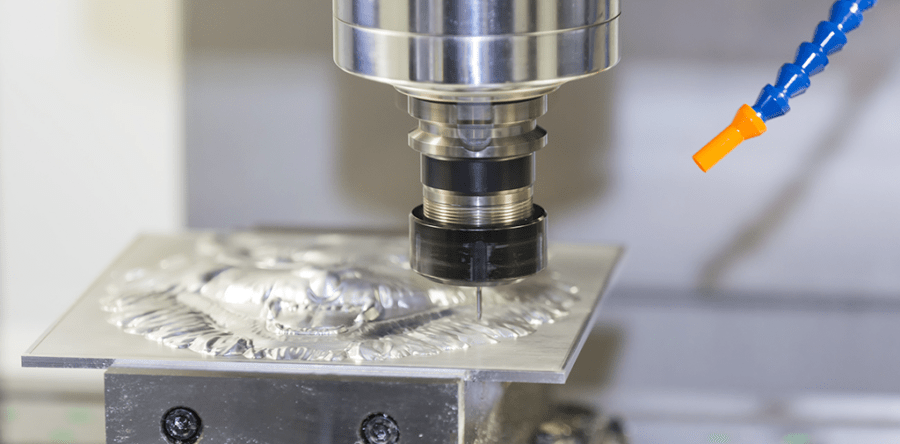

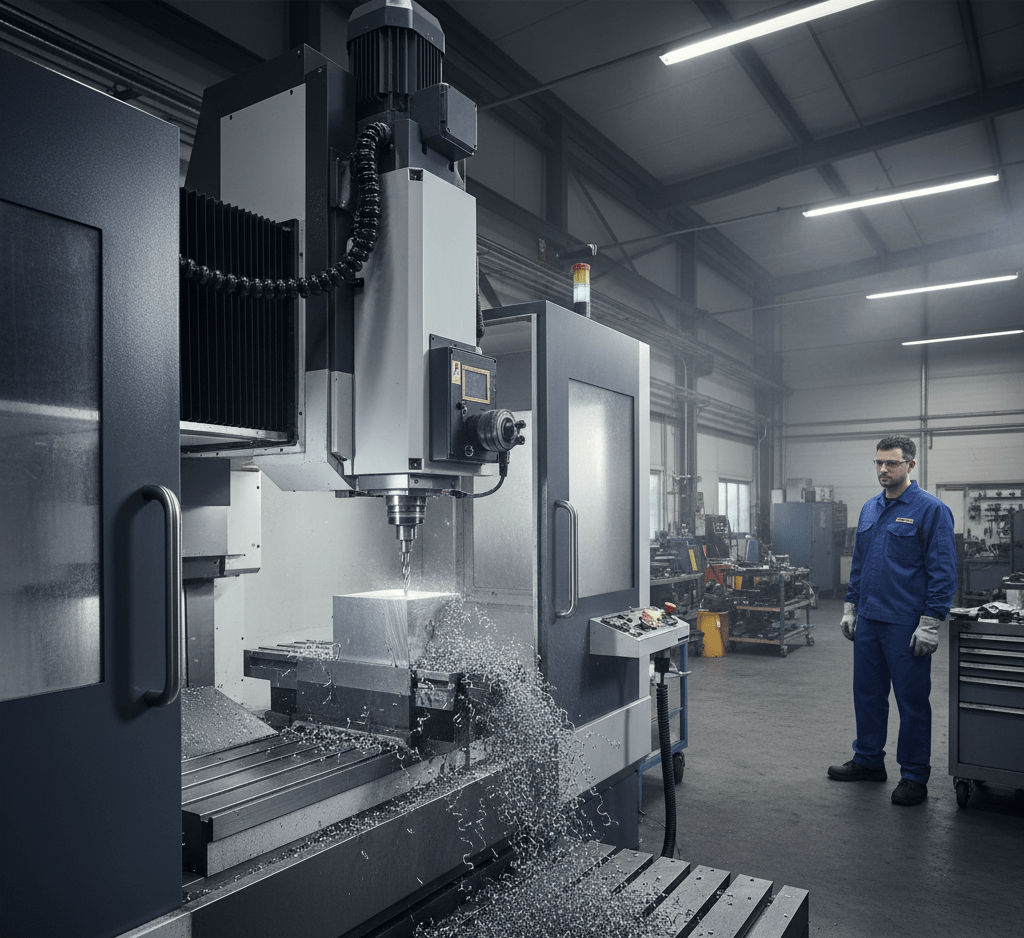

Milling is a versatile machining process that removes material from a workpiece using rotary cutting tools. Modern milling centers use computer-controlled systems to achieve consistent accuracy, high repeatability, and the ability to create complex geometries.

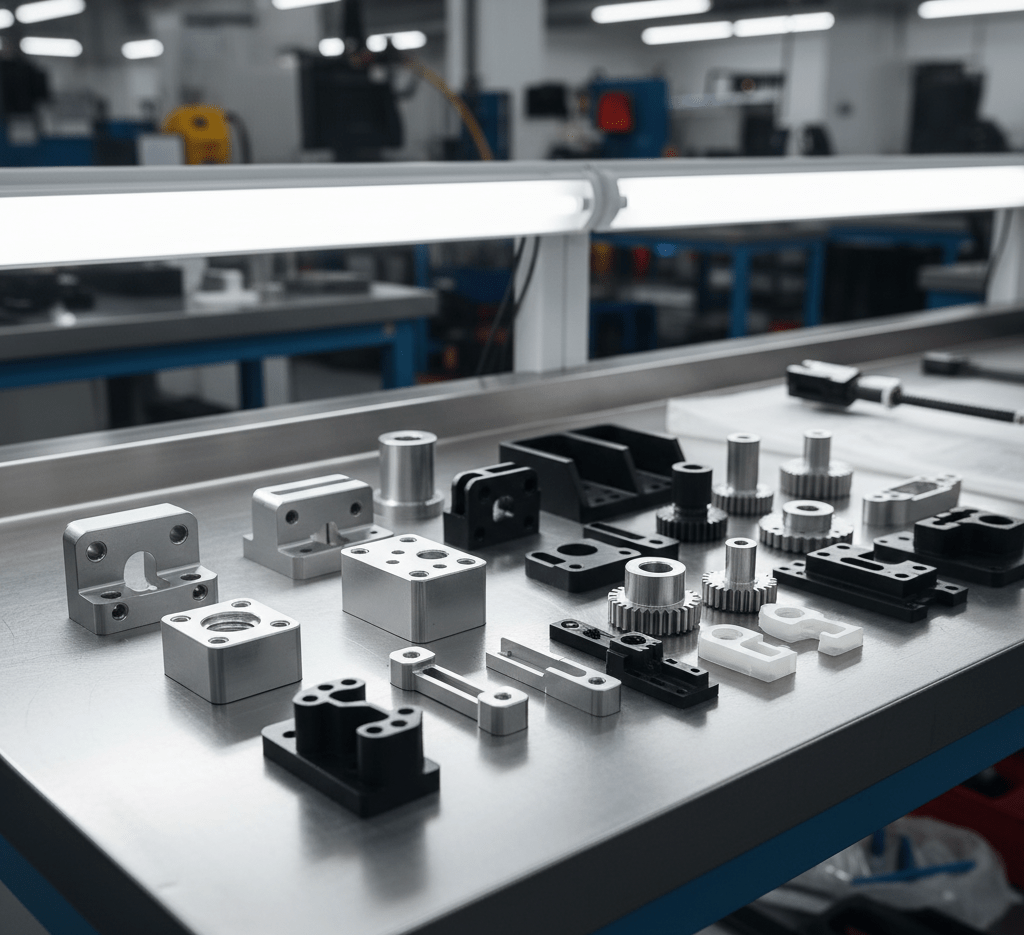

This process is applied to a wide range of materials, including metals, plastics, and composites. Its precision makes it indispensable in aerospace, automotive, electronics, and industrial machinery applications. Milling can produce flat surfaces, angled cuts, slots, pockets, and other intricate features.

If you want to know more about the CNC Milling, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.We leave you some articles that may be of interest to you https://sumiparts.us/services/plastic-injection-design-service/

Different Milling Operations Explained

Milling involves several specialized operations:

-

Face milling: Produces smooth, flat surfaces quickly and efficiently.

-

Peripheral milling: Removes material along the edges of a workpiece, ideal for grooves and slots.

-

End milling: Uses a tool with teeth on the tip to produce pockets, holes, and complex 3D shapes.

-

Angular milling: Cuts angled surfaces or chamfers with high precision.

Operators often combine these operations in a single setup, allowing for both efficiency and complex part production. CNC-controlled machines allow precise coordination of multiple axes, reducing the need for secondary finishing.

Materials Compatible with Milling

Milling works with a variety of materials, including:

-

Metals: aluminum, steel, stainless steel, titanium, brass

-

Plastics: nylon, PEEK, PTFE, Delrin

-

Composites: carbon fiber, reinforced plastics, layered polymers

Tool selection, spindle speed, and feed rate are determined by the material type. Proper lubrication and cooling enhance surface finish, prolong tool life, and prevent heat-related issues, ensuring durable and precise components.

Material Preparation and Setup

Before milling, careful preparation is essential. Surfaces must be clean and free of debris, oil, or coatings that could interfere with the cut. The workpiece is clamped securely to prevent vibration. Advanced setups may include laser alignment tools or cameras to ensure exact positioning.

Proper planning of the machining sequence and tool paths maximizes material usage and reduces waste. This preparation is crucial for achieving smooth edges and dimensional accuracy.

Advantages and Industrial Uses

offers several benefits:

-

High precision: Consistently achieves tight tolerances.

-

Versatility: Capable of producing simple or highly complex shapes.

-

Surface quality: Provides smooth finishes suitable for functional and aesthetic purposes.

-

Efficiency: CNC automation reduces production time.

Typical applications include engine components, molds, structural parts, medical instruments, and custom machinery. Milling is often combined with polishing, coating, or assembly to produce finished components ready for industrial use.

Tips for Optimal Performance

To ensure high-quality milling:

-

Choose the correct cutting tool and spindle speed.

-

Secure the workpiece to prevent vibration.

-

Monitor coolant or lubrication flow to avoid overheating.

-

Inspect parts regularly for dimensional accuracy.

-

Simulate CNC operations before full-scale production to prevent errors.

Following these practices reduces tool wear, minimizes material waste, and ensures consistent, accurate results.

Emerging Trends and Final Thoughts

Modern milling integrates multi-axis CNC machines, hybrid additive/subtractive systems, and AI-assisted programming. These advancements allow for even more complex geometries, faster production, and higher precision.

Milling remains a cornerstone of modern manufacturing, providing flexible, efficient, and high-quality machining for a wide range of industries. Its ability to adapt to different materials and part complexities makes it essential for industrial production, prototyping, and custom fabrication.

Common Machining Methods

Machining includes various approaches depending on the part geometry and material:

-

Surface milling: Produces flat or contoured surfaces efficiently.

-

Edge profiling: Removes material along the perimeter to create grooves, slots, or decorative shapes.

-

Complex pocketing: Allows creation of cavities, holes, and 3D features in a single setup.

-

Angled or chamfer cuts: Shapes edges to precise specifications for assembly or design requirements.

Advanced systems often integrate multiple methods automatically, minimizing manual adjustments and speeding up production cycles.

Future of Precision Machining

Advances in multi-axis and hybrid machining systems allow for more complex geometries and faster production cycles. AI-assisted programming and real-time monitoring improve efficiency while reducing errors. This makes modern machining a core component of industrial fabrication, prototyping, and specialized manufacturing.

Introduction to Material Shaping

Modern manufacturing relies on precise material removal techniques to create functional and aesthetic components. Among these methods, machining with rotary cutting tools allows for complex shapes and surfaces with minimal manual intervention. Operators can tailor the process to a wide range of materials, ensuring each component meets strict dimensional and functional requirements.