Polycarbonate Injection and Extrusion: High-Performance Solutions for Modern Industry

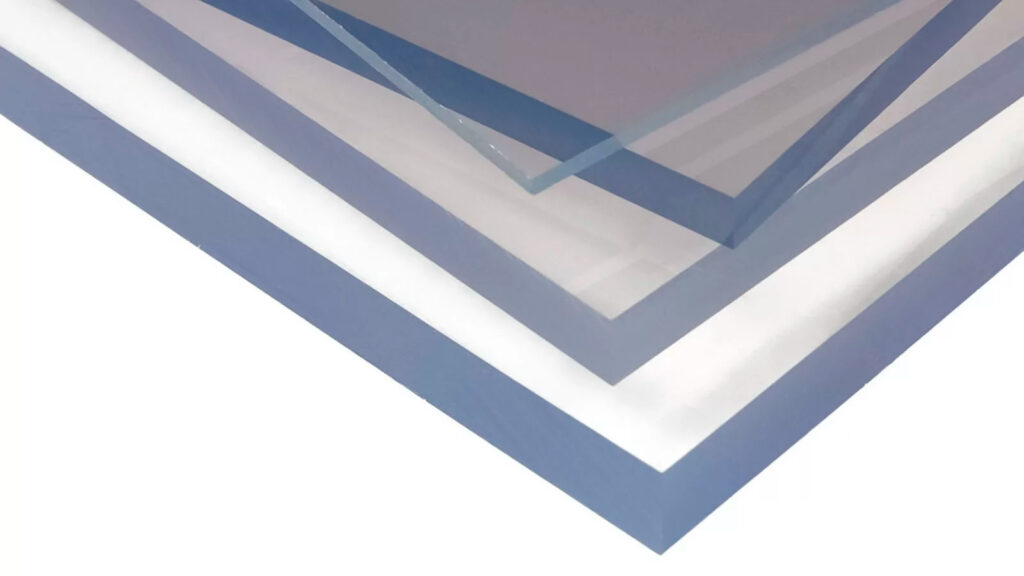

POLYCARBONATE (PC) belongs to a family of high-performance thermoplastics known for their versatility, transparency, and mechanical strength. It is a material that combines durability and lightness, making it ideal for applications where impact resistance, temperature stability, and optical clarity are required. Polycarbonate can be easily molded, machined, and thermoformed, adapting perfectly to a wide range of industrial and commercial uses.

Its unique composition allows it to maintain excellent dimensional stability, even under continuous mechanical stress or extreme environmental conditions. Thanks to this, polycarbonate components are often found in demanding environments where other plastics or even metals might fail.

In SUMIPARTS SAS we are at the forefront of injection molding and extrusion processes of POLYCARBONATE, with the full range that is available in terms of natural and color formulations.

POLYCARBONATE INJECTION MOLDING

The polycarbonate injection molding process allows us to produce precision-engineered parts with excellent dimensional accuracy and smooth finishes. Using our state-of-the-art CNC-controlled injection machines, we can achieve complex geometries that maintain consistent quality even at high production volumes.

This process is particularly useful in sectors such as:

Automotive: manufacturing of headlights, interior housings, dashboards, and transparent components.

Industrial: protective covers, guards, electrical housings, and machine parts.

Construction: lighting elements, skylight panels, and structural fittings that require high impact resistance.

Among the main advantages of our polycarbonate injection process are:

Outstanding impact resistance: ideal for applications that require durability and reliability.

Excellent dimensional stability: maintains accuracy and prevents deformation under stress.

Optical clarity: allows the production of transparent or translucent components with great visual appeal.

Thermal resistance: maintains its integrity under both high and low temperatures.

High production efficiency: short cycle times and consistent quality reduce costs and delivery times.

At SUMIPARTS S.A.S., our injection capabilities go beyond standard manufacturing. We offer custom tooling, material optimization, and post-processing options, ensuring that each part performs as intended in its final application.

Advanced Polycarbonate Injection Processes

At Sumiparts SAS, our Polycarbonate Injection processes are designed to deliver high-precision components with exceptional consistency and quality. Polycarbonate Injection is one of the most versatile thermoplastic manufacturing techniques, allowing us to produce parts with complex geometries, tight tolerances, and superior mechanical and optical properties. By combining state-of-the-art injection molding machines with an experienced engineering team, we ensure that every project benefits from innovative solutions and efficient production cycles.

The Polycarbonate Injection process begins with a careful selection of high-quality polycarbonate resin, which is then melted and injected into precision-engineered molds. These molds can be customized for multi-cavity production, enabling large-scale manufacturing while maintaining exacting quality standards. Thanks to Polycarbonate Injection, parts such as protective housings, machine guards, automotive light covers, and industrial panels can be produced with high repeatability and minimal post-processing.

One of the main advantages of Polycarbonate Injection is the ability to create complex geometries that would be difficult or impossible to achieve with other materials or manufacturing methods. This makes it ideal for applications in the automotive, industrial, and construction sectors, where components must combine strength, durability, and aesthetic appeal. Additionally, Polycarbonate Injection allows for quick production cycles, reduced material waste, and consistent dimensional accuracy, which translates to cost savings and faster time-to-market for clients.

Our advanced Polycarbonate Injection line also supports customization in color, transparency, and surface finishes, meeting the specific design and functional requirements of each project. This flexibility allows Sumiparts SAS to develop parts that are not only functional but also visually appealing, enhancing the overall value of the product.

Furthermore, Polycarbonate Injection components exhibit excellent impact resistance, high thermal stability, and long-term durability, making them suitable for demanding environments. From outdoor applications exposed to UV radiation to industrial equipment subject to mechanical stress, Polycarbonate Injection ensures parts retain their structural integrity and performance over time.

At Sumiparts SAS, our commitment to quality in Polycarbonate Injection extends beyond production. Our engineering team collaborates closely with clients during the design phase, offering insights on mold design, material selection, and process optimization. This ensures that every injection-molded polycarbonate part is tailored to the client’s requirements, delivering consistent performance and reliability.

In summary, our Polycarbonate Injection capabilities provide a comprehensive solution for manufacturing high-quality thermoplastic components. By leveraging cutting-edge technology, skilled personnel, and rigorous quality control, Sumiparts SAS delivers durable, precise, and visually appealing parts suitable for automotive, industrial, and construction applications. Whether it’s small custom batches or high-volume production runs, Polycarbonate Injection at Sumiparts SAS guarantees efficiency, accuracy, and superior results for every project.

Main Applications and Advantages of Polycarbonate Injection and Extrusion (PC)

Polycarbonate Injection and Extrusion (PC) represents one of the most versatile and efficient solutions in modern engineering plastics manufacturing. Polycarbonate is a high-performance thermoplastic widely used in the automotive, industrial, and construction sectors for its exceptional combination of impact resistance, optical transparency, and thermal stability. This material maintains its physical integrity under pressure, heat, and continuous use, making it ideal for applications that demand long-term performance and reliability. In construction and architecture, polycarbonate injection and extrusion products are commonly used in transparent and translucent ceilings, domes, skylights, and façade panels, taking advantage of their lightweight structure and excellent light transmission.

The use of cellular polycarbonate sheets allows greater energy efficiency, structural stability, and reduced installation costs, while providing outstanding UV resistance and weather protection. In the industrial sector, solid polycarbonate components are preferred for machinery guards, safety enclosures, and protective covers, since their impact resistance can be up to 200 times higher than acrylic sheets of similar thickness. This property ensures safety, durability, and clarity in manufacturing environments that require strong, transparent protection materials.

Polycarbonate extrusion profiles are also essential in industrial applications for guides, connectors, and custom-shaped elements that combine rigidity and flexibility in a single product. In the advertising and signage industry, polycarbonate injection components are increasingly chosen for illuminated signs, display panels, and outdoor advertising structures, due to their superior optical quality, color stability, and resistance to yellowing caused by sunlight.

These properties ensure that signage maintains its brightness and professional appearance over time, even in challenging outdoor conditions. The main advantages of polycarbonate include exceptional impact resistance, superior transparency, high mechanical strength, rigidity, thermal deformation resistance, electrical insulation capacity, and excellent UV protection. These features make it a preferred material for high-performance industrial and architectural projects.

At SUMIPARTS S.A.S., we specialize in polycarbonate injection molding and extrusion processes, using CNC-controlled machinery and advanced CAD/CAM engineering tools to ensure tight tolerances, precision, and consistent quality in every part we produce. Our production capacity allows us to manufacture high-volume orders with optimal efficiency, short lead times, and strict quality assurance. Whether for industrial safety components, architectural coverings, or custom transparent parts, polycarbonate injection and extrusion represent a reliable and sustainable choice. At SUMIPARTS S.A.S., our commitment is to accompany each client through the entire process — from product design to final production — ensuring innovation, performance, and durability in every project.

SUMIPARTS SAS has an experienced team of staff, who with their knowledge and skills can provide an excellent service and final product tailored to the needs.

If you want to know more about developments in Polycarbonate injection, in SUMIPARTS SAS we will be very willing to collaborate. We want to provide you with the best services at your fingertips.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 318 728 7721 WhatsApp click here , or by sending an email to info@sumiparts.com. Our technical team will be at your disposal to assist you.