How Sumiparts Executes High-Volume Plastic Extrusion

Sumiparts SAS plastic extrusion is a process that presents high productivity and is one of the most important for obtaining plastic shapes in volume.

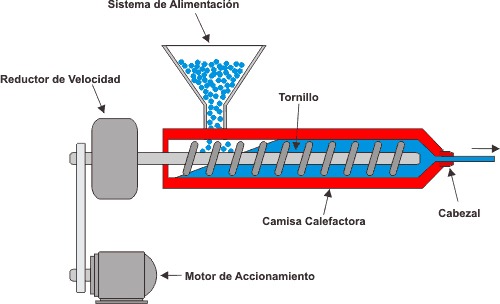

Sumiparts has the equipment, tools and qualified personnel to carry out this operation, which is very simple, once the conditions have been established of operation. The extrusion of rigid and flexible plastics of Sumiparts SAS, consists of giving a defined shape to the plastic through the use of pressure, thrust and temperature.

The material that is supplied to the machine is loaded through the use of a container in the upper part of the extruder called a hopper, which uniformly deposits the material inside the screw, later it will be subjected to temperature and fusion, in order to thus push this material into the cavities of the mold and obtain our profile or packaging footage to the desired size.

Uses in the plastic extrusion market

The extrusion of rigid and flexible plastics is a highly demanded market line which must provide the market for profiles, coatings and finishes, products that meet the needs of individual and / or general projects

We specialize in the development of extruded profiles, with established market lines and line products, we also have new development lines where it is executed:

Manufacture of molds for rigid extrusion

Manufacture of molds for flexible extrusion

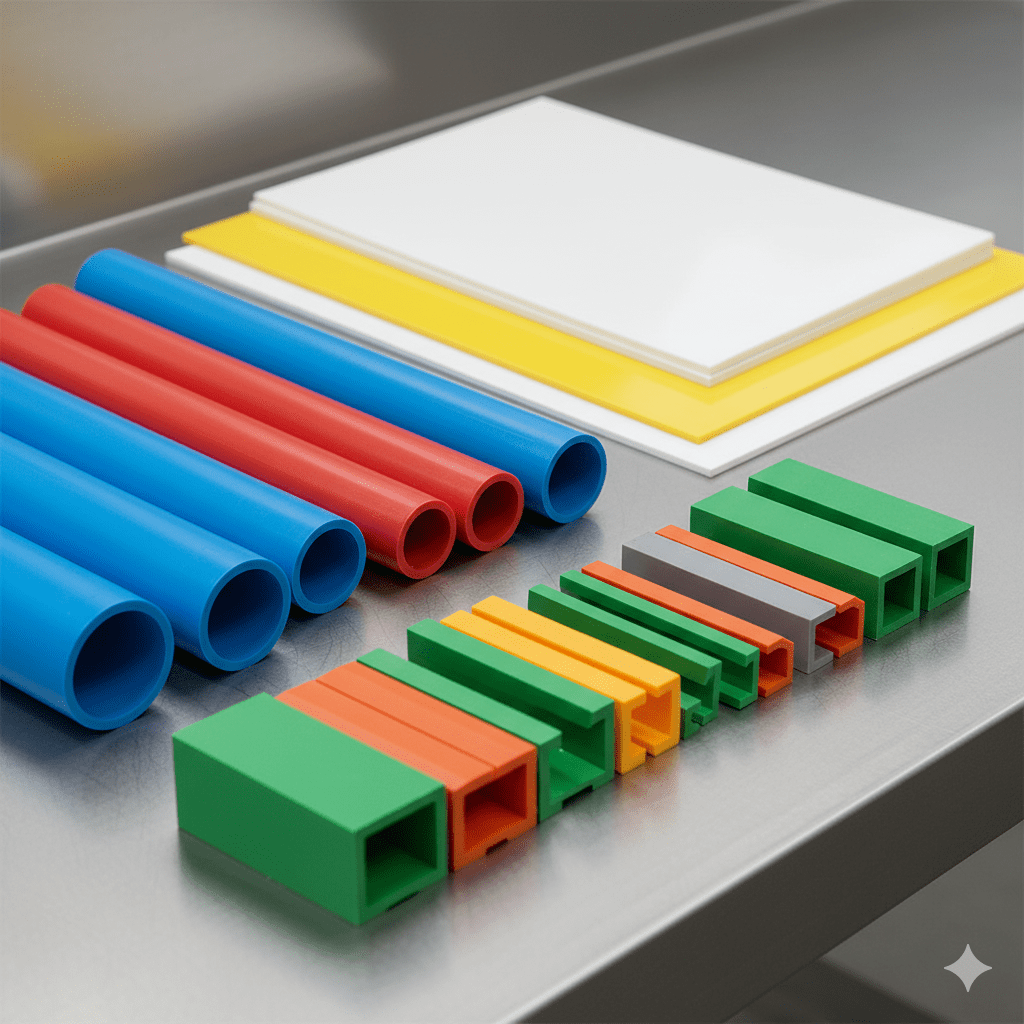

The Sumiparts plastic extrusion process, It is an efficient method of manufacturing profiles and semi-finished products, or also known as shapes, with large wall thicknesses and dimensions.

The inventory of products and semi-finishes goes from the creation of hoses, tubes, sheets, shutter sheets, windows, water flow channels, filaments, save brooms, among others.

With Sumiparts the plastic extrusion process has several advantages, such as the variety of

shapes, lower costs, lighter parts and products, and high productivity, efficiency and quality.

If you want to know more about this Plastic Extrusion service in SUMIPARTS we will be more than happy to serve you. We want to provide you with the best services at your fingertips. Get in touch with us by calling Pbx: +57 748 22 13, Cel: 313 699 13 56 whatsApp or by sending an email to info@sumiparts.com We leave you some articles that may be of interest to you, Injection molding

Advantages of Plastic Extrusion

-

High Efficiency: Continuous operation allows large-volume production with minimal downtime.

-

Design Flexibility: Complex profiles with consistent dimensions can be created.

-

Cost-Effectiveness: Efficient use of material reduces waste.

-

Lightweight and Durable Components: Extruded plastics provide strength without excessive weight.

-

Customizability: Color, material type, and mechanical properties can be tailored to requirements.

These advantages make plastic extrusion a go-to method for producing functional and aesthetic components in industries ranging from automotive and construction to consumer goods and electronics.

Common Applications of Extruded Plastics

Plastic extrusion enables the production of a wide variety of products, including:

-

Pipes and tubing for plumbing, chemical transport, or air ducts

-

Window and door profiles for construction

-

Protective casings for electrical cables

-

Custom shapes for automotive or industrial assemblies

-

Consumer goods such as plastic rods, sheets, and trims

The versatility of extrusion allows manufacturers to meet both mechanical performance requirements and aesthetic standards, ensuring components are reliable, durable, and visually appealing.

Tips for Optimizing Plastic Extrusion

-

Select the Right Material: Consider mechanical, thermal, and chemical resistance properties.

-

Optimize Die Design: Proper die engineering prevents defects like warping or uneven thickness.

-

Control Process Parameters: Temperature, screw speed, and cooling rate directly affect dimensional accuracy and surface finish.

-

Implement Quality Control: Inline monitoring, surface inspection, and regular calibration ensure consistent production quality.

Conclusion

Plastic extrusion is a highly versatile and efficient method for producing durable components with precise dimensions. By combining the right materials, optimized machinery, and skilled operation, manufacturers can create products that meet both performance and aesthetic requirements.

From custom profiles to standardized pipes and tubes, plastic extrusion continues to be a cornerstone in modern industrial production, delivering reliable and cost-effective solutions across multiple sectors.