Key Features and Machining Considerations of Nylon

Nylon, a semi-crystalline polymer from the polyamide family, stands out for its exceptional mechanical properties, high impact resistance, and wear performance. Thanks to its combination of strength, lightness, and chemical stability, nylon has become a preferred material for precision-engineered components used in automotive, industrial, and construction applications.

To ensure the highest reliability during machining, nylon requires controlled stabilization, including gradual heating near its melting point. This process relieves internal stresses, prevents cracking, and maintains dimensional stability throughout the manufacturing cycle.

CNC MACHINING: At SUMIPARTS, we specialize in CNC machining of nylon components with tight tolerances and the ability to produce complex geometries with superior surface finishes. Our Engineering Department combines advanced CAD design and CAM programming to optimize machining strategies, material utilization, and production efficiency. Whether for prototype development or large-scale production, our CNC machining process ensures accuracy, repeatability, and timely delivery.

Our experience in CNC nylon machining allows us to deliver consistent results for components that require both mechanical strength and precise performance — from custom bushings and gears to rollers, guides, and fittings.

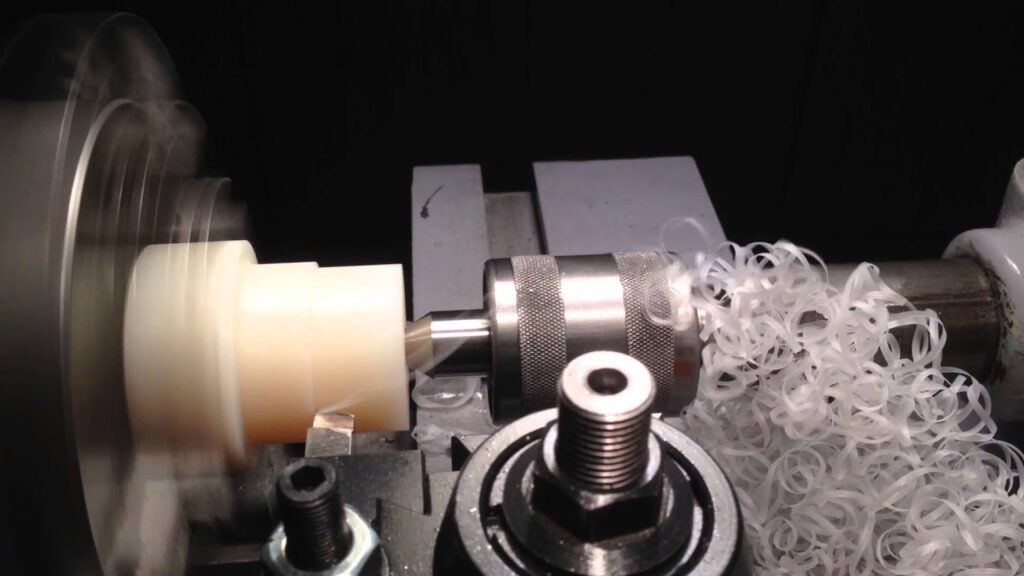

CNC TURNING: When it comes to manufacturing cylindrical nylon parts, CNC turning offers unmatched precision and efficiency. Using automatic lathes and Swiss-type turning centers, we produce parts that meet tight dimensional tolerances while reducing production costs. This process is ideal for high-volume nylon components such as spacers, pulleys, and custom sleeves, where surface finish and concentricity are essential to ensure long-term reliability and performance.

CNC MILLING: Our CNC milling centers are equipped with multi-axis technology that allows us to machine nylon components with high precision and complex designs. This process is ideal for custom fabrications, prototypes, and mass production, ensuring dimensional accuracy and consistent quality across every batch. With advanced tool path simulation, CAM optimization, and automated production lines, SUMIPARTS guarantees fast turnaround times and cost-effective manufacturing solutions.

At SUMIPARTS SAS, our comprehensive nylon machining capabilities — including CNC milling, turning, and drilling — allow us to meet the highest industrial standards. We combine cutting-edge machinery, technical expertise, and rigorous quality control to deliver precision-engineered nylon parts that exceed expectations in both performance and durability.

Advantages and Industrial Applications of Nylon

Nylon is one of the most versatile and reliable engineering plastics used today across automotive, industrial, and construction sectors. Its unique combination of mechanical strength, durability, and resistance to wear makes it an ideal material for manufacturing precision components that must perform under demanding conditions.

Main Advantages

Nylon stands out among technical polymers due to its excellent balance between strength, flexibility, and processability. The main benefits of this material include:

High mechanical strength, hardness, and rigidity, ensuring durability even under mechanical stress.

Superior damping capacity, which reduces vibrations and noise in mechanical assemblies.

Outstanding fatigue resistance, maintaining performance after repeated cycles of use.

Excellent wear and abrasion resistance, extending part lifespan and reliability.

Low friction and good sliding properties, allowing smooth operation without excessive heat generation.

Capability to operate without lubrication, making it ideal for clean and maintenance-free systems.

Silent performance, reducing operational noise in moving assemblies.

Moderate moisture absorption, which must be controlled to maintain dimensional stability and precision.

Thanks to these features, their components are highly efficient in dynamic applications, where strength, friction reduction, and wear resistance are essential.

Industrial and Automotive Applications

In the automotive industry, nylon is widely used to produce valve seats, gears, bearings, bushings, fuel tanks, and cams. Its lightweight and robust characteristics contribute to energy efficiency and mechanical reliability, even under continuous vibration and temperature variations.

In the industrial sector, nylon plays a crucial role in manufacturing electrical insulators, conveyor components, rollers, spacers, and structural parts that demand high wear resistance and precision machining. Its ability to operate without lubrication makes it particularly suitable for environments with strict contamination control, such as food or pharmaceutical production systems.

SUMIPARTS Expertise

At SUMIPARTS SAS, we combine advanced CNC technology with in-depth knowledge of polymer behavior to produce nylon components of exceptional precision and performance. Our highly trained engineering and machining team designs, programs, and manufactures each part according to strict quality standards, ensuring dimensional accuracy, consistency, and long-term reliability.

Whether for automotive assemblies, industrial equipment, or custom-made parts, SUMIPARTS provides comprehensive design, machining, and production solutions tailored to your specific needs — delivering high-performance nylon components that meet the most demanding applications.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 318 728 7721, or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.