Neoprene Uses: Industrial Applications and Advantage

Neoprene is a synthetic rubber obtained from the polymerization of chloroprene, known for its excellent mechanical strength, chemical resistance, and flexibility across a wide temperature range. It is one of the most versatile materials in modern industry, ideal for demanding environments that require durability and performance.

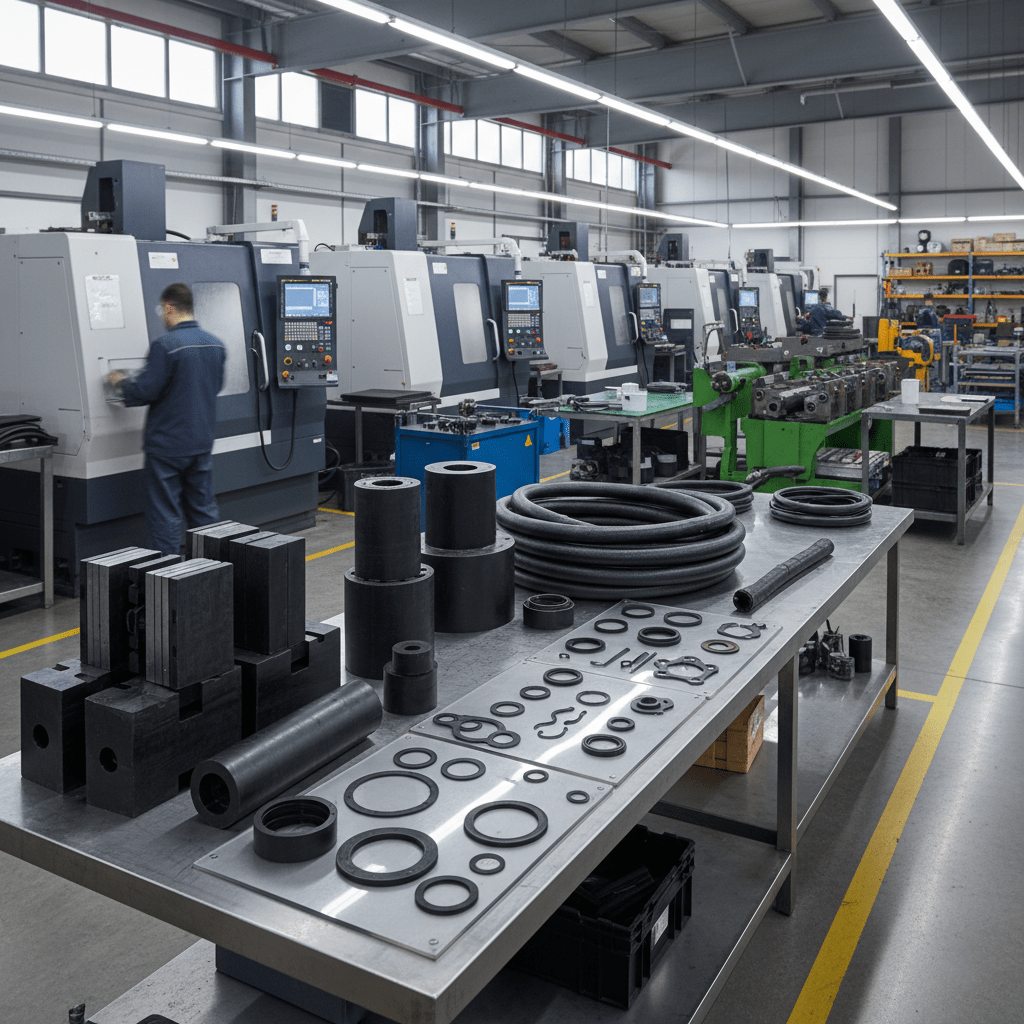

At Sumiparts SAS, we use this material in multiple industrial processes due to its resistance to oils, weathering, and compression, making it suitable for both static and dynamic applications. It can be molded, vulcanized, or extruded according to each client’s specifications, ensuring precision and consistency

Main Industrial Applications

Used across various industries such as construction, automotive, mechanical engineering, and energy for the following applications:

-

Bridge bearings and vibration dampers

Neoprene’s high elasticity and load-bearing capacity make it ideal for bridge bearings, vibration isolators, and structural supports. These components effectively absorb dynamic loads, reducing stress and prolonging the lifespan of bridges and civil structures. They are widely implemented in modern infrastructure projects, ensuring long-term performance, reliability, and safety under constant pressure and changing environmental conditions.Mechanical seals and gaskets

Through precision molding, we produce mechanical seals and gaskets that ensure complete tightness in systems exposed to fluids, gases, or high pressure. These components maintain their flexibility and sealing integrity even under extreme temperature variations and continuous operation. Their adaptability makes them suitable for a wide variety of applications, from heavy industrial machinery to delicate instrumentation systems.Flexible hoses and expansion joints

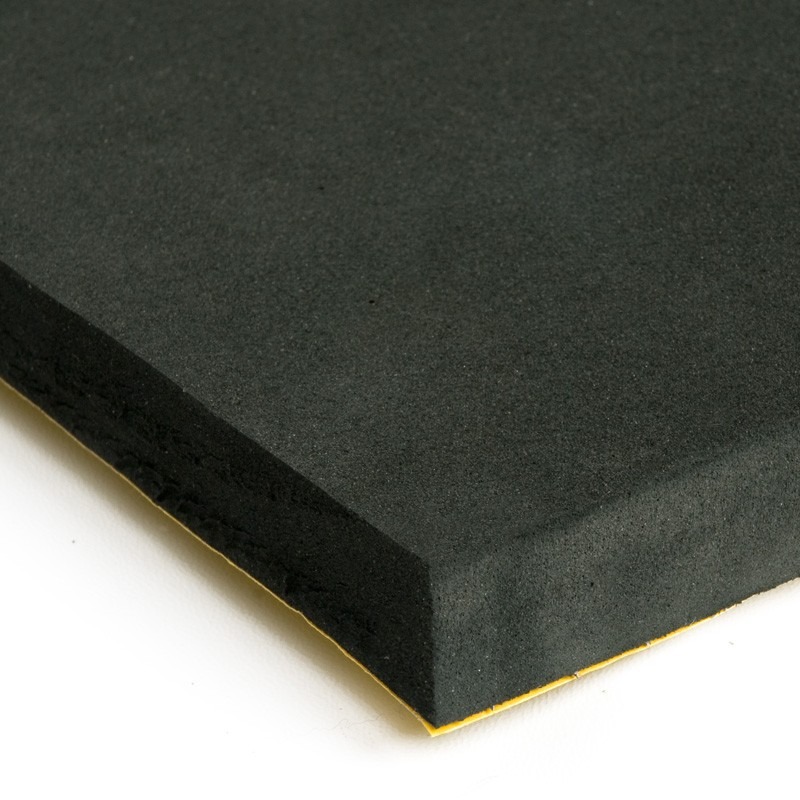

Our hoses and expansion joints are designed to absorb vibration, compensate for movement, and minimize noise in hydraulic and industrial pipeline systems. Their chemical resistance and adaptability make them ideal for the construction, petrochemical, and machinery sectors. They also contribute to reducing maintenance costs and operational downtime, enhancing productivity and system stability.Protective covers and insulators

We manufacture protective components that provide excellent resistance to corrosion, moisture, and temperature fluctuations. These parts are essential for protecting mechanical systems, electrical components, and industrial assemblies operating in harsh environments. Their reliability and long service life make them a practical choice for continuous-use applications and demanding field operations.Shock absorbers and anti-slip pads

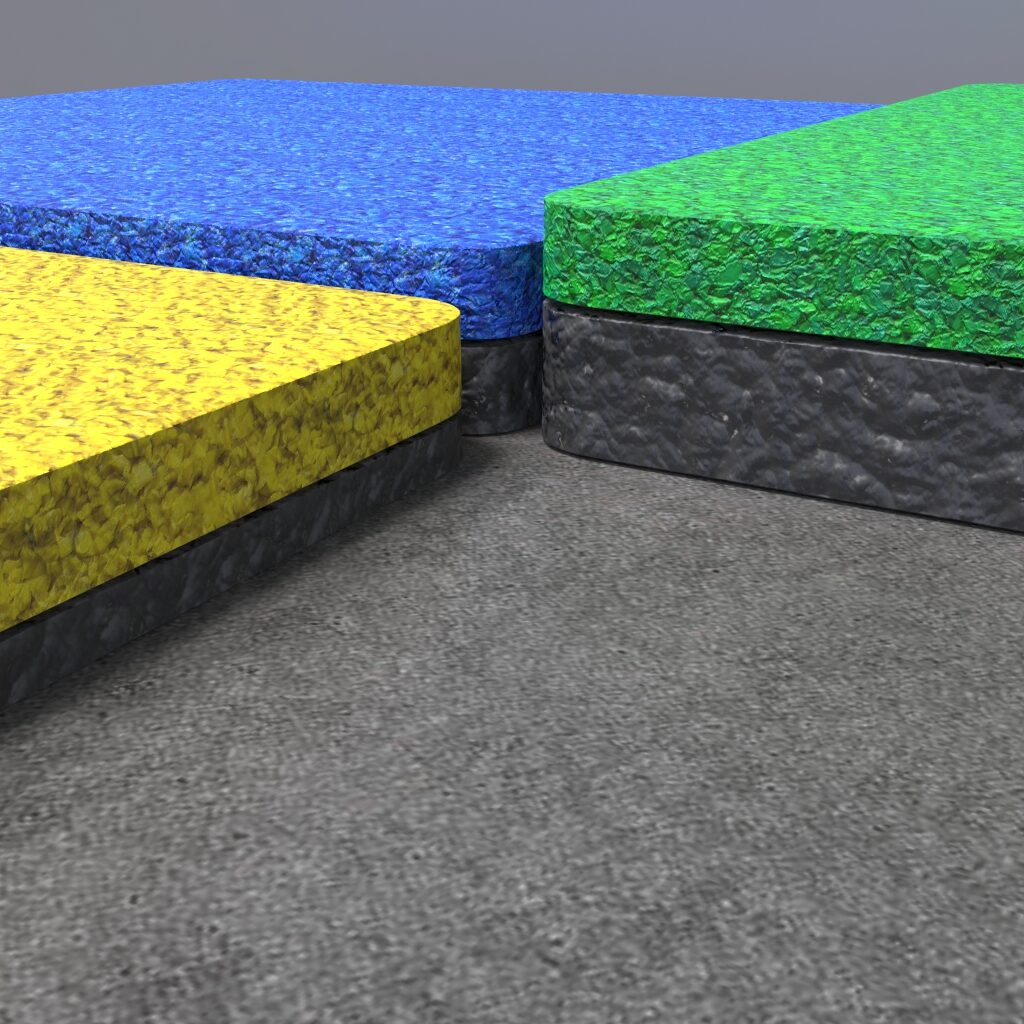

The combination of elasticity and durability allows the creation of shock absorbers, pads, and anti-slip supports for heavy machinery and industrial equipment. These products help reduce impact, vibration, and wear, ensuring stability and safety in continuous-use operations. Their robust design allows for better performance in high-load conditions, contributing to safer and more efficient workspaces.

Vulcanization and Extrusion Processes

At Sumiparts SAS, we specialize in Neoprene vulcanization, offering comprehensive solutions for the development and manufacturing of custom components. Our process covers every stage — from mold design and construction to vulcanizing and high-volume production — ensuring consistent quality, precision, and durability in every part.

Through vulcanized Neoprene, we can form a wide variety of industrial components, such as seals, gaskets, supports, vibration dampers, and protective elements. This process enhances the material’s elasticity, mechanical strength, and resistance to deformation, making it ideal for heavy-duty and high-performance applications in the construction, automotive, and mechanical industries.

We also offer Neoprene extrusion services, developing continuous profiles and shapes according to the specific geometries required by our clients. Our extrusion processes enable large-scale production while maintaining tight tolerances and uniform surface finishes, fully adapted to industrial standards.

At Sumiparts SAS, our experienced engineering and production teams ensure excellent service and tailor-made solutions, combining technical expertise with modern machinery and strict quality control. The result is a final product that meets your exact requirements and performs reliably in demanding environments.

Whether you need vulcanized or extruded Neoprene components, we provide the flexibility, capacity, and precision needed to bring your industrial projects to life.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click here , by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you