¿How the milling process is carried out and what types can we find?

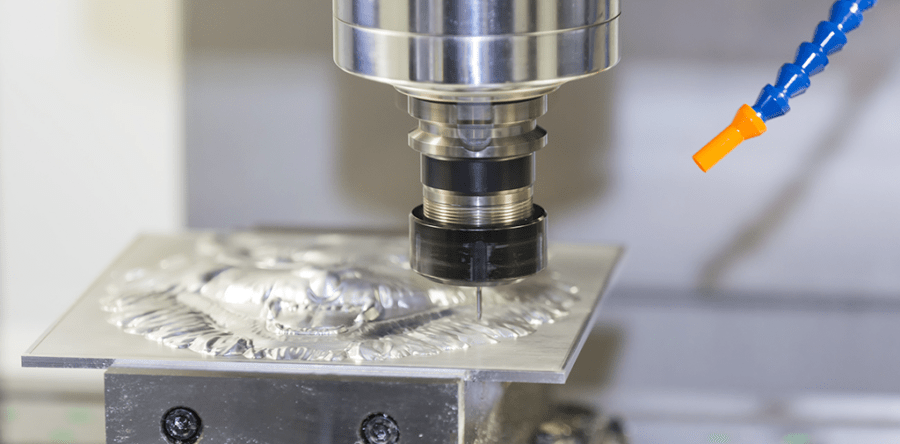

The milling process for accurate machining is the metal cutting for the creation of precision mechanical parts . This process is carried out with a machine called milling machine, capable of making all kinds of cuts and shapes with a finish that is impossible to do by hand. The machine consists of four parts: cutter, shaft, stabilizer and interface.

For the milling process, at the end of the cutter there is an interchangeable head for different cutters. Mills are small toothed wheels with cutting edges that pull the shavings out of the metal when they rotate . Depending on the type of cut required, one type of cutter or another is used. The cutter is attached to the axis or carriage, which is the moving part of the milling machine, capable of making almost any movement in the three directions. The stabilizer or table is the part where the part to be machined is placed and blocks, in some milling machines the table also moves. And the interface or command is the device from which the machine is operated.

What is computer numerical control (CNC)?

There are different types of the most advantageous milling machine is the CNC type (Computerized Numerical Control) , because it is robotized and has greater precision and accuracy in the machining process. Its operation is based on a coordinate system where the computer controls the movement to perform precision machining. Depending on the machine, the cutter can mold even a perfect metal sphere, performing movements in five axes .

The metal milling process performed by an operator of a CNC milling machine consists of four steps. The first is to program the computer from the interface using the CAM (Computer-Aided Manufacturing) manual programming software, or CAD (Computer-Aided Design) automatic programming . It is done by inserting a series of numbers and letters after having made the appropriate calculations.

Once programmed, the material to be worked and the necessary cutter are placed depending on the type of cut to be made. The next thing is to start the milling process for precision machining through the interface. Finally the quality of the finishes is reviewed.

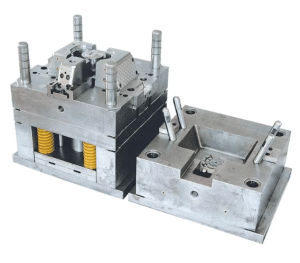

Finishes achieved with the CNC milling process

With the computer numerical control milling machine , or CNC , and various types of milling , all kinds of finishes are achieved in the process of machining.

- Cut milling , the process is the most basic because it is the first to be used to adapt the material to the needs of the job.

- Planned , process that flatten the surface.

- Square , used to create a stepped surface.

- Turner´s cube , to create cubic shaped pieces.

- Shape grooving , to make T-shaped grooves.

- From keyway grooving , a type of asymmetric trapezoidal groove.

- Lathe-milling , to make holes and external milling when surrounding the piece. Depending on the type of milling, a different bur is used

If you want to know more about the CNC Milling, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.We leave you some articles that may be of interest to you https://sumiparts.us/services/plastic-injection-design-service/