What Is Electrostatics Painting?

Electrostatics painting is a highly efficient coating process that uses electrically charged particles to create smooth, even finishes on conductive surfaces. By applying an opposite charge to the part and the paint, the coating is naturally attracted to the surface, resulting in uniform coverage and minimal overspray.

This technology is widely used in industries such as automotive, furniture, and manufacturing, where consistency, durability, and visual quality are essential. It not only enhances appearance but also increases the protection of materials against corrosion, wear, and environmental exposure.

How the Process Works

The electrostatic process relies on a simple but powerful principle — opposite charges attract. When paint particles are atomized, they receive an electrical charge, while the object being painted is grounded. As the charged particles are sprayed, they are drawn toward the surface, wrapping around edges and corners for complete coverage.

This method reduces paint waste and eliminates the need for multiple passes, making it both economical and environmentally friendly. Once the paint is applied, the coated object is cured — either by heat or air — to achieve a strong, long-lasting bond.

💡 Tip: Keeping proper grounding and adjusting voltage levels are key to maintaining coating uniformity and avoiding excessive buildup in recessed areas.

Benefits of Electrostatics Painting

This technique offers several clear advantages compared to traditional painting methods:

-

Electrostatics Painting offers several clear advantages compared to traditional coating methods:

Superior coverage: The electrostatic charge allows paint to wrap evenly around all surfaces, ensuring complete coverage even on complex geometries.

Reduced waste: Because Electrostatics Painting minimizes overspray, it delivers efficient material use and reduces paint loss.

High durability: Coatings applied through Electrostatics Painting resist corrosion, scratches, and chemical damage, extending the life of metal components.

Consistent appearance: Surfaces treated with Electrostatics Painting achieve a smooth, professional, and uniform finish suitable for industrial and decorative applications.

Eco-friendly process: Electrostatics Painting consumes less paint and generates lower emissions, making it a sustainable choice for modern manufacturing.

Time savings: Faster application and reduced rework increase productivity and efficiency.

Applications Across Industries

Electrostatics painting is used in a wide range of industrial and commercial sectors:

-

Automotive parts: Chassis, frames, rims, and accessories.

-

Appliances: Refrigerators, washing machines, and metal panels.

-

Furniture: Metal chairs, tables, and office structures.

-

Construction: Metal beams, handrails, and decorative elements.

-

Machinery and tools: Components requiring durable and clean finishes.

Its adaptability makes it one of the most trusted techniques for achieving aesthetic appeal and long-lasting protection in metal fabrication and finishing.

Practical Recommendations for a Perfect Finish

To ensure the best results in Electrostatics Painting, several factors must be controlled throughout the process. Each step directly impacts coating quality, adhesion, and long-term durability.

-

Maintain clean and dry surfaces: Any trace of dust, oil, or moisture can interfere with paint adhesion. Proper surface preparation ensures that the electrostatic charge is evenly distributed, allowing the coating to fully wrap around the part.

-

Verify correct grounding: Since Electrostatics Painting depends on attraction between charged paint particles and the grounded object, proper grounding is essential. It ensures that the paint reaches even hidden corners and complex geometries, achieving full and uniform coverage.

-

Use high-quality coatings: Always select premium powder or liquid coatings designed specifically for electrostatic application. The right formulation improves transfer efficiency, reduces waste, and enhances the final finish’s resistance to corrosion and impact.

-

Adjust voltage and spray distance: Fine-tuning the electrostatic voltage and maintaining an optimal distance between the spray gun and the part prevents overcoating or uneven layers. These adjustments are crucial for achieving a consistent, smooth surface across all components.

-

Control curing temperature and time: After coating, Electrostatics Painting requires precise curing. Maintaining the correct temperature and time allows the paint to crosslink effectively, forming a durable bond that resists wear, heat, and chemical exposure.

When performed correctly, Electrostatics Painting delivers a smooth, uniform, and highly durable coating that enhances both the performance and aesthetic value of metal products. It provides manufacturers with a cleaner, more efficient, and environmentally responsible alternative to traditional painting methods — ensuring consistent results even in large-scale industrial applications.

Conclusion

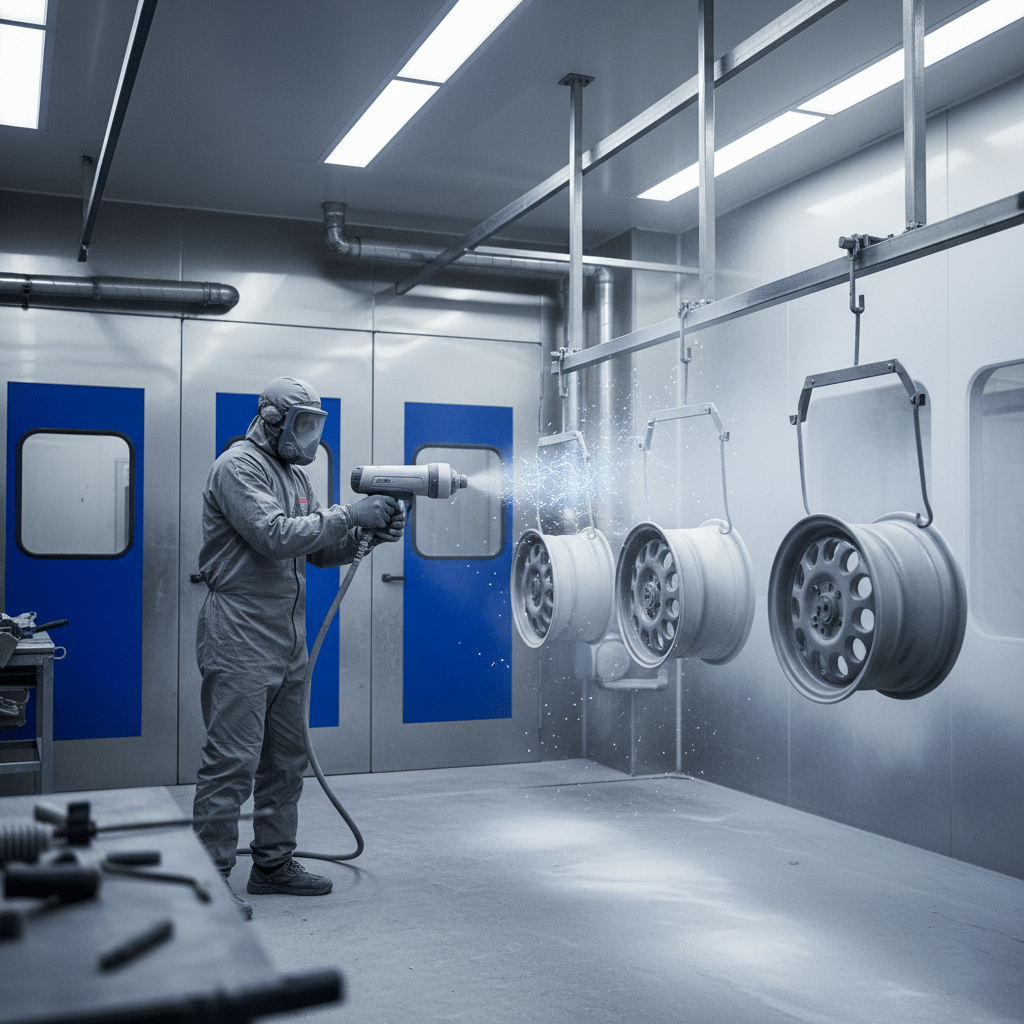

Electrostatic Paint is classified as a coating that is applied as a fluid, dry powder, which is usually used to create a hard finish that is more resistant than conventional paint.

The process is carried out in facilities equipped that provide a curing oven, cabinets for application with electrostatic guns and usually an air transport chain, where the parts are hung, usually aluminum parts, auto parts or electrical appliances.

In the manufacturing industry electrostatic painting finds a wide application, from a qualitative point of view, it is easier to apply and from an ecological point of view, it does not create any problems for the operators and the environment.

Electrostatic paint can be applied to the following materials such as steel, aluminum, and galvanized metals. With colorants, all shades of color can be obtained, including the RAL 7032 range.

If you want to know more about the Electrostatics Painting, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.