Electropolishing of Stainless Steel – Precision Surface Finishing

Electropolishing of Stainless Steel is an advanced electrochemical finishing process designed to enhance the performance, durability, and visual quality of stainless steel components. Through the electropolishing of stainless steel surfaces, a very thin layer of material is uniformly removed to eliminate micro-roughness, weld residues, and surface imperfections. This precise and controlled stainless steel electropolishing process creates a smooth, bright, and reflective surface that significantly improves corrosion resistance, hygiene, and overall cleanability. The result is a high-quality, passivated finish that enhances both the appearance and functionality of electropolished stainless steel parts, making it ideal for demanding applications in industrial, architectural, food, and medical environments.

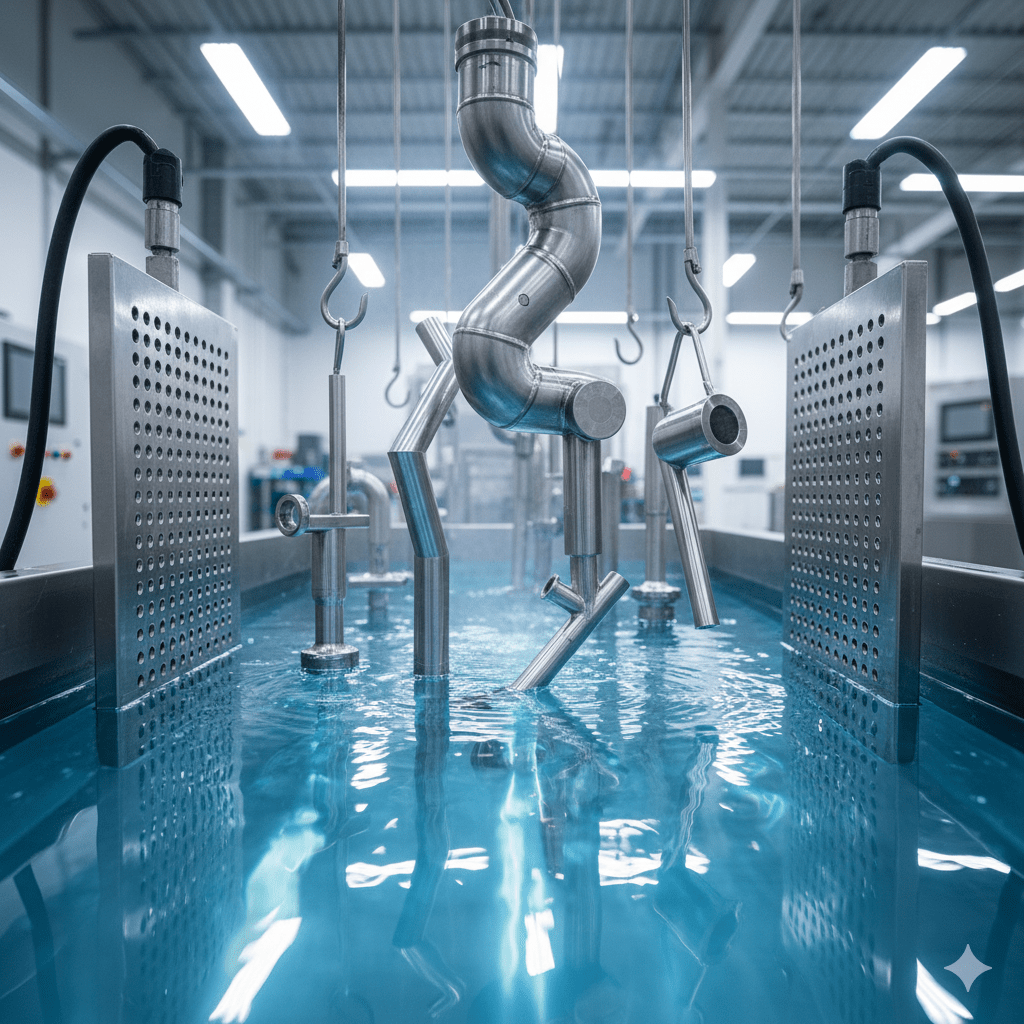

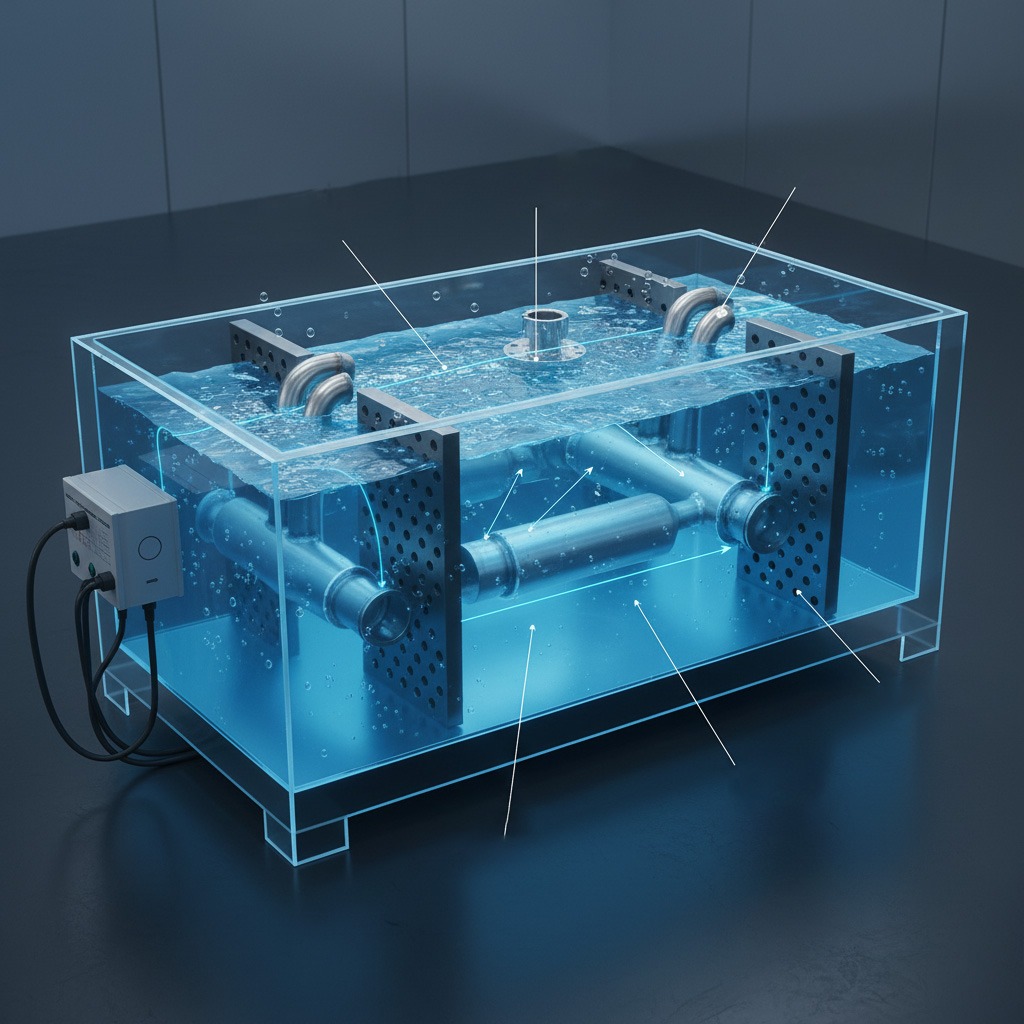

At Sumiparts SAS, we specialize in professional Electropolishing of Stainless Steel, combining advanced technology with a team of skilled technicians to achieve consistent, repeatable results. Our stainless steel electropolishing service begins with the careful cleaning and preparation of each component, followed by immersion in a precisely controlled electrolytic bath. During the electropolishing process, the surface layer of the stainless steel is dissolved at a microscopic level under specific voltage and current parameters, resulting in a defect-free, mirror-like finish. This method not only provides a highly aesthetic and smooth surface but also enhances the passive layer, offering superior protection against corrosion, oxidation, and contamination.

Thanks to our expertise in Electropolishing of Stainless Steel, we deliver products that meet the most rigorous industrial and sanitary standards. Every electropolished stainless steel component we produce demonstrates increased resistance to wear, improved chemical stability, and extended service life. Whether used in industrial machinery, architectural fixtures, medical instruments, or food processing equipment, our electropolished finishes guarantee durability, hygiene, and outstanding performance in every application.

If you would like to learn more about our Stainless Steel Electropolishing service, SUMIPARTS is happy to assist you. We want to provide you with the best services at your fingertips. Contact us by calling +57 748 22 13, mobile (+57) 313 699 13 56, or by emailing info@sumiparts.com. Our technical team will be ready to assist you.

Applications of Electropolished Stainless Steel:

- Industrial Equipment:

The Electropolishing of Stainless Steel process is widely used to improve the durability of components exposed to harsh chemicals, moisture, and corrosion-prone environments. Electropolished stainless steel surfaces offer superior corrosion resistance, smoother finishes, and longer operational life in chemical plants, water treatment systems, and industrial machinery. The process ensures that every stainless steel component maintains high structural integrity and consistent performance under demanding conditions. - Food and Beverage Industry:

In food processing environments, Electropolishing of Stainless Steel plays a crucial role in meeting hygiene and safety standards. The process eliminates microscopic roughness, making stainless steel surfaces non-porous and easy to clean. This minimizes bacterial growth, improves sanitation, and ensures compliance with FDA and food-grade requirements. From tanks, conveyors, and piping to processing equipment, electropolished stainless steel delivers exceptional cleanliness and reliability. - Medical and Pharmaceutical Equipment:

The stainless steel electropolishing process guarantees sterile and contaminant-free surfaces, essential for medical instruments, surgical tools, and pharmaceutical assembly systems. Electropolished stainless steel resists chemical sterilization, prevents contamination, and maintains its mirror-like surface finish even after repeated cleaning cycles. This makes it indispensable in hospitals, laboratories, and pharmaceutical production environments. - Construction and Architecture:

In architectural and construction projects, Electropolishing of Stainless Steel enhances both aesthetic and functional properties. Handrails, decorative panels, and façade elements benefit from a brilliant, uniform shine and increased weather resistance. The electropolished stainless steel finish not only elevates visual appeal but also protects surfaces from oxidation, UV exposure, and pollution damage, ensuring long-term durability in outdoor and indoor environments. - Automotive and Aerospace:

For automotive and aerospace components, Electropolishing of Stainless Steel significantly improves mechanical performance and longevity. By reducing surface roughness, the process minimizes friction and wear in parts such as engine housings, exhaust components, hydraulic fittings, and structural frames. Electropolished stainless steel ensures better fatigue resistance, lower maintenance needs, and greater energy efficiency — all critical factors in high-performance engineering sectors.

Benefits of Electropolishing Stainless Steel:

Electropolishing of Stainless Steel is a highly effective surface finishing process that enhances the durability, cleanliness, and appearance of stainless steel components. This electrochemical technique removes a thin layer of material from the surface, eliminating imperfections and improving both functional and aesthetic performance. It is a preferred method in industries that demand precision, hygiene, and corrosion resistance.

- Improved Corrosion Resistance:

One of the main advantages of Electropolishing of Stainless Steel is its ability to create a passivated and uniform surface layer that protects against oxidation, rust, and chemical corrosion. This property makes it an essential process for food processing equipment, pharmaceutical machinery, and marine applications, where metal surfaces are constantly exposed to moisture and chemicals. - Enhanced Cleanability and Hygiene:

The stainless steel electropolishing process produces an ultra-smooth and non-porous surface, preventing the accumulation of grease, dirt, and bacteria. This makes it ideal for medical instruments, cleanroom systems, and sanitary piping, where hygiene and contamination control are crucial. The smoother surface also simplifies maintenance and extends the life of the component. - Aesthetic and Functional Finish:

In addition to technical advantages, Electropolishing of Stainless Steel offers an attractive mirror-like finish that enhances the visual appearance of industrial and decorative parts. This bright surface not only reflects light evenly but also reduces the risk of contamination by minimizing microscopic roughness. It is widely used in architectural design, high-end appliances, and visible mechanical components. - Defect and Burr Removal:

During manufacturing processes like welding, cutting, and machining, small imperfections or burrs can compromise product performance. The Electropolishing of Stainless Steel process efficiently removes micro-defects and surface irregularities, improving precision, fatigue resistance, and part reliability. This results in smoother operation and longer service life for mechanical assemblies. - Durability and Long-Term Performance:

Electropolished stainless steel surfaces maintain their mechanical strength and dimensional stability even in demanding conditions. This process extends the component’s lifespan by reducing friction, preventing corrosion, and enhancing fatigue resistance — essential in sectors like automotive, construction, and industrial manufacturing. - At Sumiparts SAS, we specialize in Electropolishing of Stainless Steel with advanced equipment and a team of trained professionals. Our goal is to deliver high-precision, high-quality finishes tailored to the unique requirements of each project. We ensure that every component passes through rigorous quality control stages, guaranteeing exceptional results in both function and appearance.

- We provide comprehensive stainless steel finishing services, including MIG, TIG, and coated welding, CNC machining, and surface treatments, ensuring consistency from raw fabrication to final polishing. Whether for industrial machinery, automotive components, or sanitary systems, Sumiparts SAS offers customized solutions that combine efficiency, performance, and superior surface quality.

- If you are looking for a reliable partner for Electropolishing of Stainless Steel, trust Sumiparts SAS to deliver excellence in every detail — from technical design to the final polished surface that enhances durability, hygiene, and visual appeal.

If you want to learn more about our neoprene vulcanization services, Sumiparts SAS is ready to collaborate. We provide technical expertise, high-quality materials, and reliable manufacturing processes to deliver custom solutions that meet the needs of modern industry.

Contact us at Tel: +57 748 22 13, mobile (+57) 313 699 13 56, or email info@sumiparts.com Our technical team is fully available to assist you with any project requiring neoprene vulcanization.