Introduction to CNC Turning at Sumiparts

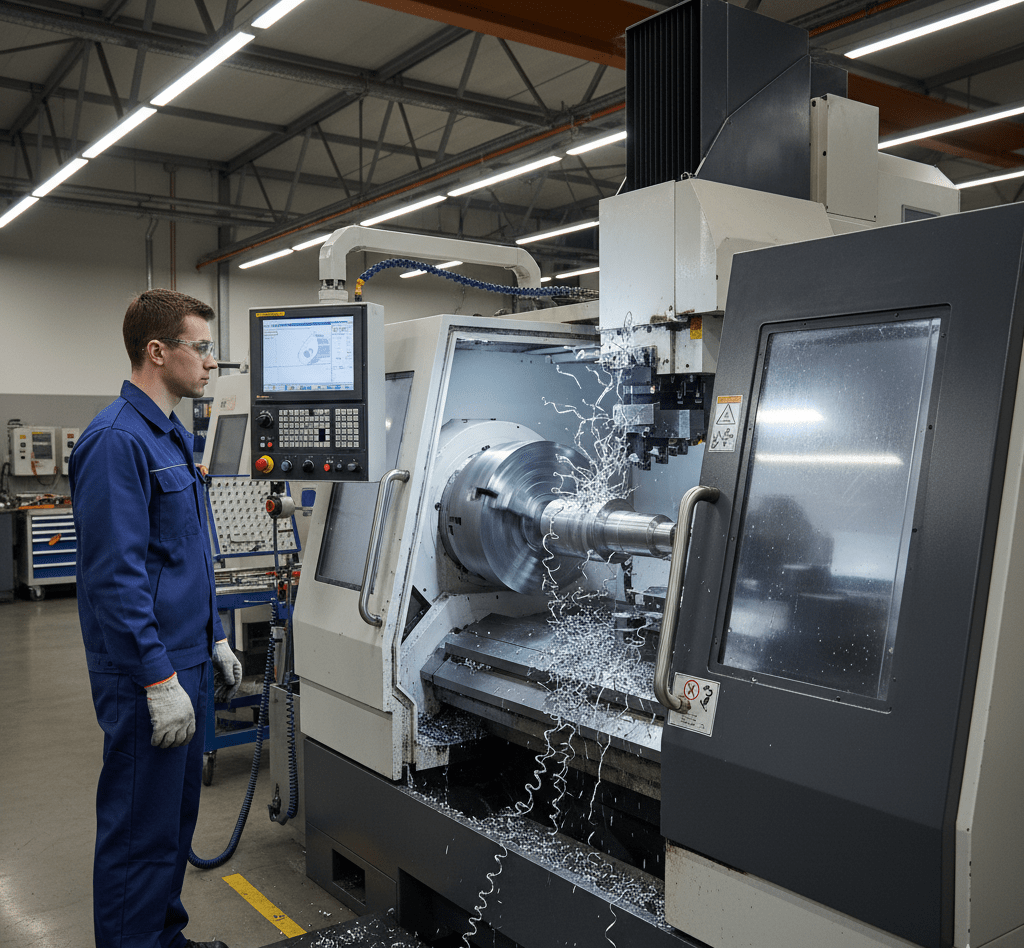

At Sumiparts, CNC Turning is a core capability that allows us to produce high-precision components for industrial clients. By using advanced lathe machining techniques, we ensure each part meets exact specifications, whether it is made from metals, plastics, or composite materials.

Our team combines technical expertise with CNC automation to provide consistent quality, repeatability, and smooth finishes. From prototyping to full production, we work closely with clients to adapt each project to their exact requirements.

Materials and Capabilities

Sumiparts handles a wide range of materials for CNC Turning:

Metals: steel, stainless steel, aluminum, brass, titanium

Plastics: PTFE, Delrin, PEEK, nylon

Composites: reinforced polymers and layered materials

Our engineers select the best tooling, cutting parameters, and cooling strategies for each material to ensure durability and precision, minimizing waste and maximizing efficiency.

Applications and Benefits

With CNC Turning at Sumiparts, clients benefit from:

High precision and consistency for industrial assemblies

Versatility for simple or complex cylindrical components

Excellent surface quality for both functional and aesthetic parts

Efficient production thanks to advanced CNC control

We produce components such as shafts, bushings, threaded parts, and custom pieces for industries including automotive, aerospace, medical, and general manufacturing.

Applications Across Industries

CNC turning is widely used in sectors that demand precision and reliability:

Automotive: shafts, bushings, gears

Aerospace: structural and engine components

Medical: surgical instruments, prosthetic parts

Industrial machinery: rollers, threaded fittings, custom connectors

The versatility of CNC turning makes it suitable for both small-batch prototyping and large-scale production runs.

Quality Control and Inspection

Precision machining requires regular inspection to maintain dimensional accuracy. Common methods include:

Using micrometers and calipers for basic measurements

Coordinate Measuring Machines (CMM) for 3D part verification

Surface finish testers to ensure smoothness and tolerance compliance

By monitoring quality at each stage, manufacturers ensure consistent results and reduce rework or scrap

Tooling and Process Optimization

Selecting the right cutting tools is critical for CNC turning efficiency. Carbide inserts, coated tools, and specialized geometries reduce wear and ensure high-quality finishes. Additionally, optimizing spindle speeds, feed rates, and depth of cut for specific materials can extend tool life and prevent overheating or vibration.

Emerging Trends in CNC Turning

The field is evolving with the integration of AI-assisted programming, IoT-connected machines, and hybrid additive/subtractive systems. These advancements enable:

Faster production cycles

Reduced setup times

Real-time monitoring for predictive maintenance

Enhanced capability to produce complex geometries

Manufacturers can now achieve higher precision while minimizing errors and increasing overall efficiency.

The types of lathe for the turning process

Front : For the manufacture of short pieces, but with large diameter.

Vertical : When the main axis is vertical starting from the ground.

CNC lathe : It is the lathe using numerical control and is presented as the definitive lathe process for machining parts.

Automatic : To make it work in an automated way, a rod is inserted into a tube with a head and adjusted with clamping pieces.

Parallel : It has a chip starter whose cutting movement adjusts to the rotating part. It requires qualified personnel.

Stages of the turning process in machining of materials

Working times:

- Loading and unloading : All the time spent fixing the piece. This time changes depending on the size or weight of the piece.

- Cut : The necessary time to make all the required cuts.

- Tool replacement : The time spent replacing the tool which is at the end of its useful life.

If you want to know more about the CNC Turning, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.