Aluminum is a non-ferromagnetic metal, which represents the third most common element in the earth’s crust. Unlike other metals, it stands out for its low density and high corrosion resistance. Several alloys can be obtained, which allow to increase their mechanical strength (up to 690 MPa). It

it is characterized by being good conductor of electricity and heat and is easy to machine. Its obtaining is economical making it the most used metal after steels.

Aluminium applications occur in different sectors, especially in industry, automotive and construction. They are used for the manufacture of mirrors and optical lenses, food packaging, body parts and construction has various applications, especially in decoration. The body part highlights the properties of low weight, an essential feature to improve the performance of mobile vehicles.

Sumiparts stands out for developing different work processes, thus guaranteeing excellent finishes, with precise measurements, and high production volume with timely delivery.

Processes developed in this material:

LASER CUTTING ON ALUMINUM, an excellent choice for projects where tight tolerances are essential and ease to develop cuts with complex geometries. The advantages are the speed of the process, the high production volume and excellent finishing in the cuts.

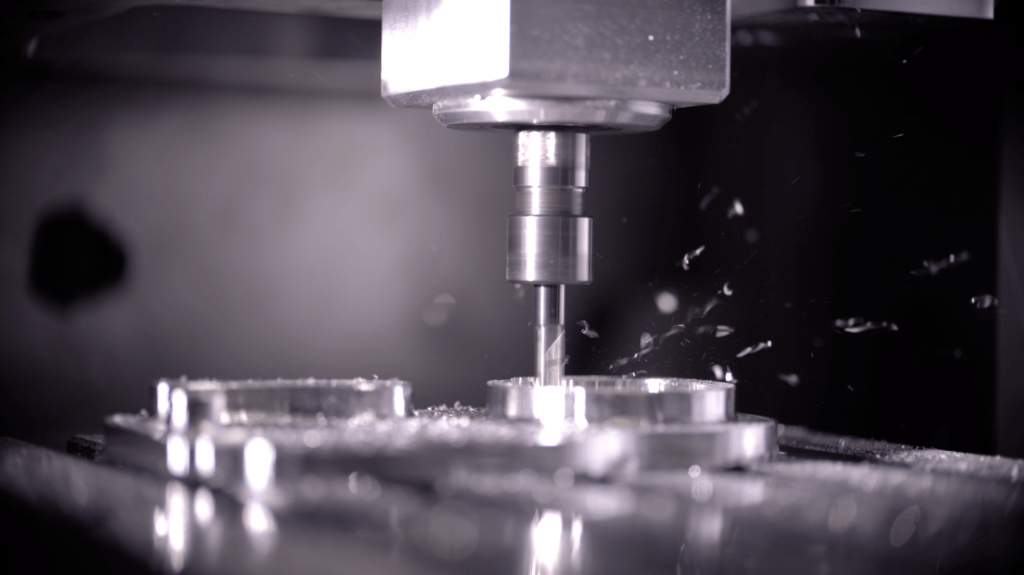

CNC MACHINING IN ALUMINUM, the main advantage of machining in aluminum is the economy in the process, as it represents a reduction of almost 60% in costs and 30% less production energy compared to steel. The efficiency of rapid machining is also highlighted, which makes the casting process not always necessary. Precision, high quality and lower production cost makes it the optimal choice when developing aluminum projects.

Aluminum Processing Techniques

Die Casting in Aluminum by Injection is one of the most widely used manufacturing techniques, especially for producing large volumes of parts with the same geometry. This process stands out for its high production speed, dimensional accuracy, and repeatability, and it allows the development of special aluminum alloys such as Zamak, which offer enhanced mechanical properties and corrosion resistance.

Welding in Aluminum requires highly skilled personnel, and at Sumiparts SAS, our team specializes in MIG, TIG, and coated welding techniques. These processes are essential for joining aluminum parts while maintaining the best surface finishes and preserving the alloy’s physical properties. Strict adherence to quality standards ensures both structural integrity and aesthetic excellence.

Bending and Rolling in Aluminum are critical processes for shaping aluminum sheets and components. We follow precise procedures that consider the direction of the grain at a microscopic level, ensuring that the bending and rolling operations do not compromise the material’s mechanical properties. This guarantees components that are strong, durable, and reliable for industrial applications.

Aluminum Finishes enhance the durability and functionality of the material. While aluminum is naturally corrosion-resistant, applying electrostatic paint, anodizing, or special surface coatings increases surface strength and allows the material to withstand harsh industrial environments. Our technical team is always available to assist clients in selecting the most appropriate finishing method for their specific project needs.

Ponte en contacto con nosotros llamando al Pbx: +57 748 22 13, teléfonos móviles (+57) 313 699 13 56, o enviando un correo a info@sumiparts.us. Nuestro equipo técnico estará en toda la disposición de atenderle.

Sumiparts SAS has an experienced team of staff, who with their knowledge and skills can provide an excellent service and final product tailored to the needs.

If you want to know more about developments in Aluminum, in Sumiparts SAS we will be at the greatest disposition to collaborate. We want to provide you with the best services at your fingertips.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click aquí , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you. Carbon steel